Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Clip-Spot Pattern<br />

<strong>Woven</strong> designs can also be obtained by using extra warp<br />

yarns or filling yarns. In a clip-spot pattern, the extra<br />

yarns interlace in the fabric to make a simple design and<br />

then float until the yarns again interlace to repeat the<br />

pattern. The long floats between the patterns are often<br />

cut away and discarded. The ends of the cut yarns are<br />

easily seen on the back of the fabric.<br />

Dotted Swiss fabric has extra filling yarn, and clipspot<br />

shirting fabric contains extra warp yarn to make<br />

the design.<br />

The durability of the design (i.e., how well the extra<br />

yarns remain in the fabric) depends on the number of<br />

interlacings in the design and the closeness of the yarns<br />

in the fabric. The additional yarns do not substantially<br />

affect the strength of the fabric.<br />

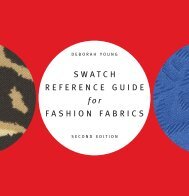

Color-and-Weave Effect<br />

A color-and-weave effect is a pattern produced in a fabric<br />

by using a certain weave and a certain arrangement<br />

of differently colored yarns in both the warp and the<br />

filling. A houndstooth pattern is a common example<br />

of a color-and-weave effect design (Figure 5.23). The<br />

houndstooth pattern shown in the chapter opening<br />

pages is made from a two-up, two-down, 45°, left-hand<br />

twill. In this example, both warp and filling have black<br />

and white yarns arranged four of one color, followed by<br />

four of the second color.<br />

Figure 5.23<br />

Houndstooth plaid.<br />

WOVEN FABRICS<br />

A 107 F<br />

Wherever a warp yarn and a filling yarn interlace,<br />

a small spot of the color of the yarn passing over is seen<br />

on the face of the cloth. The sum of the colors of all the<br />

yarns interlacing on the face produces various stripes,<br />

checks, and plaids.<br />

Technology Advancements<br />

From a design and production perspective, advances<br />

in technology have enabled the industry to produce a<br />

variety of woven fabrics more quickly and effectively<br />

than ever before. They have allowed the woven-fabrics<br />

industry the opportunity to offer value-added merchandise<br />

with a shortened production cycle. This quick<br />

turnaround has fueled new opportunities in the use of<br />

woven fabrics in broad applications for both the apparel<br />

and interior furnishings industries.<br />

The initial design can be made in minutes with<br />

the colored pattern shown on the computer screen.<br />

Any modifications and/or alternatives can be produced<br />

with the same ease. The images of the color monitors<br />

are very realistic, as are the designs that are reproduced<br />

by color printers. These computer-generated designs are<br />

sent directly to buyers anywhere in the world and when<br />

approved can be electronically transmitted to computeroperated<br />

loom systems at the textile mill.<br />

The application of various technologies allows the<br />

textile designer to work directly with the consumer<br />

(e.g., dress designer). Any changes in color or pattern<br />

can quickly be accomplished. The print hard copy that<br />

is finally approved usually has a remarkable similarity<br />

to the fabric to be made. The designer can choose the<br />

type of yarn (e.g., tightness of twist and thickness) as<br />

well as the surface (e.g., smooth or brushed, slightly<br />

blurred look).<br />

Equipment is now available that can scan a woven<br />

fabric and analyze the warp and filling yarns, colors,<br />

the cloth count, and the particular weave. This can be<br />

done to actual fabric samples that are as complex as<br />

multifaceted dobby patterns found in upholstery and<br />

men’s suiting.<br />

The fabrics can be shown as a three-dimensional<br />

object. Thus the effects of changing in yarns, fabric<br />

construction (ypi), and finish can be viewed. Also both<br />

sides of the material can be seen.<br />

The garment designer can also use a computer<br />

system to draw the garment on the screen. When the<br />

garment is completed and approved, any pattern of fabric<br />

stored in the computer can be displayed on the garment.<br />

The garment can also be displayed on a model,<br />

with the computer simulating draping, shadowing, and