You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

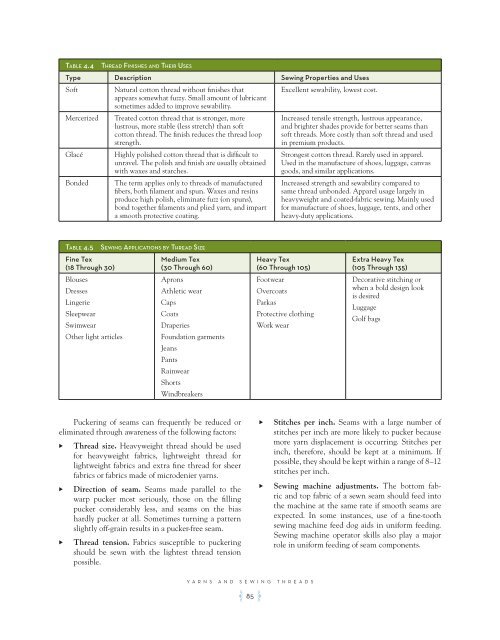

Table 4.4 Thread Finishes and Their uses<br />

Type Description Sewing Properties and Uses<br />

Soft Natural cotton thread without finishes that<br />

appears somewhat fuzzy. Small amount of lubricant<br />

sometimes added to improve sewability.<br />

Mercerized Treated cotton thread that is stronger, more<br />

lustrous, more stable (less stretch) than soft<br />

cotton thread. The finish reduces the thread loop<br />

strength.<br />

Glacé Highly polished cotton thread that is difficult to<br />

unravel. The polish and finish are usually obtained<br />

with waxes and starches.<br />

Bonded The term applies only to threads of manufactured<br />

fibers, both filament and spun. Waxes and resins<br />

produce high polish, eliminate fuzz (on spuns),<br />

bond together filaments and plied yarn, and impart<br />

a smooth protective coating.<br />

Table 4.5 sewing appliCaTions bY Thread size<br />

Fine Tex<br />

(18 Through 30)<br />

Blouses<br />

Dresses<br />

Lingerie<br />

Sleepwear<br />

Swimwear<br />

Other light articles<br />

Medium Tex<br />

(30 Through 60)<br />

Aprons<br />

Athletic wear<br />

Caps<br />

Coats<br />

Draperies<br />

Foundation garments<br />

Jeans<br />

Pants<br />

Rainwear<br />

Shorts<br />

Windbreakers<br />

Puckering of seams can frequently be reduced or<br />

eliminated through awareness of the following factors:<br />

u Thread size. Heavyweight thread should be used<br />

for heavyweight fabrics, lightweight thread for<br />

lightweight fabrics and extra fine thread for sheer<br />

fabrics or fabrics made of microdenier yarns.<br />

u Direction of seam. Seams made parallel to the<br />

warp pucker most seriously, those on the filling<br />

pucker considerably less, and seams on the bias<br />

hardly pucker at all. Sometimes turning a pattern<br />

slightly off-grain results in a pucker-free seam.<br />

u Thread tension. <strong>Fabrics</strong> susceptible to puckering<br />

should be sewn with the lightest thread tension<br />

possible.<br />

YARNS AND SEWING THREADS<br />

A 85 F<br />

Excellent sewability, lowest cost.<br />

Increased tensile strength, lustrous appearance,<br />

and brighter shades provide for better seams than<br />

soft threads. More costly than soft thread and used<br />

in premium products.<br />

Strongest cotton thread. Rarely used in apparel.<br />

Used in the manufacture of shoes, luggage, canvas<br />

goods, and similar applications.<br />

Increased strength and sewability compared to<br />

same thread unbonded. Apparel usage largely in<br />

heavyweight and coated-fabric sewing. Mainly used<br />

for manufacture of shoes, luggage, tents, and other<br />

heavy-duty applications.<br />

Heavy Tex<br />

(60 Through 105)<br />

Footwear<br />

Overcoats<br />

Parkas<br />

Protective clothing<br />

Work wear<br />

Extra Heavy Tex<br />

(105 Through 135)<br />

Decorative stitching or<br />

when a bold design look<br />

is desired<br />

Luggage<br />

Golf bags<br />

u Stitches per inch. Seams with a large number of<br />

stitches per inch are more likely to pucker because<br />

more yarn displacement is occurring. Stitches per<br />

inch, therefore, should be kept at a minimum. If<br />

possible, they should be kept within a range of 8–12<br />

stitches per inch.<br />

u Sewing machine adjustments. The bottom fabric<br />

and top fabric of a sewn seam should feed into<br />

the machine at the same rate if smooth seams are<br />

expected. In some instances, use of a fine-tooth<br />

sewing machine feed dog aids in uniform feeding.<br />

Sewing machine operator skills also play a major<br />

role in uniform feeding of seam components.