You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

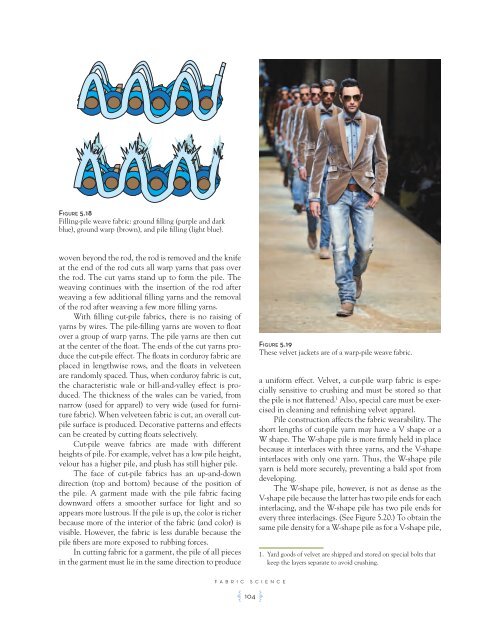

Figure 5.18<br />

Filling-pile weave fabric: ground filling (purple and dark<br />

blue), ground warp (brown), and pile filling (light blue).<br />

woven beyond the rod, the rod is removed and the knife<br />

at the end of the rod cuts all warp yarns that pass over<br />

the rod. The cut yarns stand up to form the pile. The<br />

weaving continues with the insertion of the rod after<br />

weaving a few additional filling yarns and the removal<br />

of the rod after weaving a few more filling yarns.<br />

With filling cut-pile fabrics, there is no raising of<br />

yarns by wires. The pile-filling yarns are woven to float<br />

over a group of warp yarns. The pile yarns are then cut<br />

at the center of the float. The ends of the cut yarns produce<br />

the cut-pile effect. The floats in corduroy fabric are<br />

placed in lengthwise rows, and the floats in velveteen<br />

are randomly spaced. Thus, when corduroy fabric is cut,<br />

the characteristic wale or hill-and-valley effect is produced.<br />

The thickness of the wales can be varied, from<br />

narrow (used for apparel) to very wide (used for furniture<br />

fabric). When velveteen fabric is cut, an overall cutpile<br />

surface is produced. Decorative patterns and effects<br />

can be created by cutting floats selectively.<br />

Cut-pile weave fabrics are made with different<br />

heights of pile. For example, velvet has a low pile height,<br />

velour has a higher pile, and plush has still higher pile.<br />

The face of cut-pile fabrics has an up-and-down<br />

direction (top and bottom) because of the position of<br />

the pile. A garment made with the pile fabric facing<br />

downward offers a smoother surface for light and so<br />

appears more lustrous. If the pile is up, the color is richer<br />

because more of the interior of the fabric (and color) is<br />

visible. However, the fabric is less durable because the<br />

pile fibers are more exposed to rubbing forces.<br />

In cutting fabric for a garment, the pile of all pieces<br />

in the garment must lie in the same direction to produce<br />

FABRIC SCIENCE<br />

A 104 F<br />

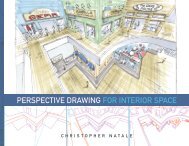

Figure 5.19<br />

These velvet jackets are of a warp-pile weave fabric.<br />

a uniform effect. Velvet, a cut-pile warp fabric is especially<br />

sensitive to crushing and must be stored so that<br />

the pile is not flattened. 1 Also, special care must be exercised<br />

in cleaning and refinishing velvet apparel.<br />

Pile construction affects the fabric wearability. The<br />

short lengths of cut-pile yarn may have a V shape or a<br />

W shape. The W-shape pile is more firmly held in place<br />

because it interlaces with three yarns, and the V-shape<br />

interlaces with only one yarn. Thus, the W-shape pile<br />

yarn is held more securely, preventing a bald spot from<br />

developing.<br />

The W-shape pile, however, is not as dense as the<br />

V-shape pile because the latter has two pile ends for each<br />

interlacing, and the W-shape pile has two pile ends for<br />

every three interlacings. (See Figure 5.20.) To obtain the<br />

same pile density for a W-shape pile as for a V-shape pile,<br />

1. Yard goods of velvet are shipped and stored on special bolts that<br />

keep the layers separate to avoid crushing.