You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Special Fabric Weaves<br />

Various special fabric weaves besides the basic weaves<br />

are also used. Three of the most common special<br />

weaves are leno weave, pile weave, and weaves that<br />

make a double cloth.<br />

Leno Weave<br />

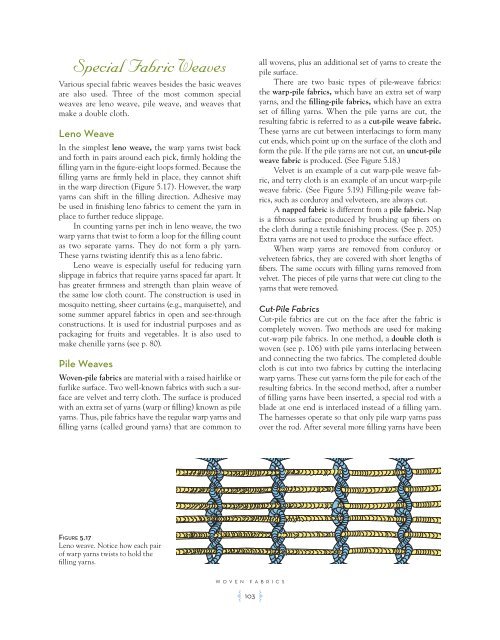

In the simplest leno weave, the warp yarns twist back<br />

and forth in pairs around each pick, firmly holding the<br />

filling yarn in the figure-eight loops formed. Because the<br />

filling yarns are firmly held in place, they cannot shift<br />

in the warp direction (Figure 5.17). However, the warp<br />

yarns can shift in the filling direction. Adhesive may<br />

be used in finishing leno fabrics to cement the yarn in<br />

place to further reduce slippage.<br />

In counting yarns per inch in leno weave, the two<br />

warp yarns that twist to form a loop for the filling count<br />

as two separate yarns. They do not form a ply yarn.<br />

These yarns twisting identify this as a leno fabric.<br />

Leno weave is especially useful for reducing yarn<br />

slippage in fabrics that require yarns spaced far apart. It<br />

has greater firmness and strength than plain weave of<br />

the same low cloth count. The construction is used in<br />

mosquito netting, sheer curtains (e.g., marquisette), and<br />

some summer apparel fabrics in open and see-through<br />

constructions. It is used for industrial purposes and as<br />

packaging for fruits and vegetables. It is also used to<br />

make chenille yarns (see p. 80).<br />

Pile Weaves<br />

<strong>Woven</strong>-pile fabrics are material with a raised hairlike or<br />

furlike surface. Two well-known fabrics with such a surface<br />

are velvet and terry cloth. The surface is produced<br />

with an extra set of yarns (warp or filling) known as pile<br />

yarns. Thus, pile fabrics have the regular warp yarns and<br />

filling yarns (called ground yarns) that are common to<br />

Figure 5.17<br />

Leno weave. Notice how each pair<br />

of warp yarns twists to hold the<br />

filling yarns.<br />

WOVEN FABRICS<br />

A 103 F<br />

all wovens, plus an additional set of yarns to create the<br />

pile surface.<br />

There are two basic types of pile-weave fabrics:<br />

the warp-pile fabrics, which have an extra set of warp<br />

yarns, and the filling-pile fabrics, which have an extra<br />

set of filling yarns. When the pile yarns are cut, the<br />

resulting fabric is referred to as a cut-pile weave fabric.<br />

These yarns are cut between interlacings to form many<br />

cut ends, which point up on the surface of the cloth and<br />

form the pile. If the pile yarns are not cut, an uncut-pile<br />

weave fabric is produced. (See Figure 5.18.)<br />

Velvet is an example of a cut warp-pile weave fabric,<br />

and terry cloth is an example of an uncut warp-pile<br />

weave fabric. (See Figure 5.19.) Filling-pile weave fabrics,<br />

such as corduroy and velveteen, are always cut.<br />

A napped fabric is different from a pile fabric. Nap<br />

is a fibrous surface produced by brushing up fibers on<br />

the cloth during a textile finishing process. (See p. 205.)<br />

Extra yarns are not used to produce the surface effect.<br />

When warp yarns are removed from corduroy or<br />

velveteen fabrics, they are covered with short lengths of<br />

fibers. The same occurs with filling yarns removed from<br />

velvet. The pieces of pile yarns that were cut cling to the<br />

yarns that were removed.<br />

Cut-Pile <strong>Fabrics</strong><br />

Cut-pile fabrics are cut on the face after the fabric is<br />

completely woven. Two methods are used for making<br />

cut-warp pile fabrics. In one method, a double cloth is<br />

woven (see p. 106) with pile yarns interlacing between<br />

and connecting the two fabrics. The completed double<br />

cloth is cut into two fabrics by cutting the interlacing<br />

warp yarns. These cut yarns form the pile for each of the<br />

resulting fabrics. In the second method, after a number<br />

of filling yarns have been inserted, a special rod with a<br />

blade at one end is interlaced instead of a filling yarn.<br />

The harnesses operate so that only pile warp yarns pass<br />

over the rod. After several more filling yarns have been