You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

the same appearance as when the fabric is turned so<br />

that the edge that was at the top is at the bottom. Thus,<br />

it usually does not make any difference in appearance<br />

with these fabrics if a garment is made with its parts<br />

placed from top-to-bottom or if its parts are turned 180°<br />

and placed bottom-to-top. In fact, most mass-produced<br />

apparel is cut this way to interlock patterns efficiently.<br />

Nevertheless, this could be undesirable because there<br />

may be a slight difference in color or luster that is not<br />

noticeable in a smaller piece of fabric but is obvious in<br />

the full garment.<br />

Yarns Per Inch: A Measure<br />

of Fabric Quality<br />

The yarns per inch in a fabric is given by two numbers<br />

with an × between them. For example, 80 × 74 (pronounced<br />

“eighty-by-seventy-four”) means 80 yarns per<br />

inch in the warp and 74 yarns per inch in the filling.<br />

The first number is for warp yarns per inch and the second<br />

is for filling yarns per inch. A fabric with the same<br />

number of yarns per inch in both directions is said to<br />

be square. An 80-square print cloth has 80 ends and 80<br />

picks per inch. The yarns per inch in the warp and in<br />

the filling is known as the fabric count, fabric density,<br />

or cloth count.<br />

Yarns per inch is a measure of fabric quality. Two<br />

broadcloths may differ in price because one has more<br />

yarns per inch. A higher number of yarns per inch gives<br />

the fabric more strength, more weight, better hand,<br />

reduced possibility of yarns shifting out of place (yarn<br />

distortion; see p. 324), and better abrasion resistance.<br />

Increasing the yarns per inch also increases the cost of<br />

the fabric.<br />

The type numbers given for sheeting are based on<br />

the number of yarns per square inch. The sum of the<br />

yarns per inch in the warp and the yarns per inch in the<br />

filling is referred to as the type number. For example, if<br />

sheeting has 100 ends and 100 picks per inch, the type<br />

number is 200 (100 plus 100). It is also referred to as 200count.<br />

For other fabrics, the value is given as 100 × 100,<br />

and not as a sum.<br />

Historically, manufacturers of sheets with a cloth<br />

count of 100 × 100 made of single yarns would indicate<br />

a 200 thread count on the package. Recently some<br />

manufacturers of sheets have counted ply yarns as two<br />

separate yarns when indicating the thread count. Thus<br />

the same sheet made of 2 ply yarns might indicate a 400<br />

thread count. This confusion triggered a concern for<br />

the industry as well as the retailers and resulted in a<br />

FABRIC SCIENCE<br />

A 96 F<br />

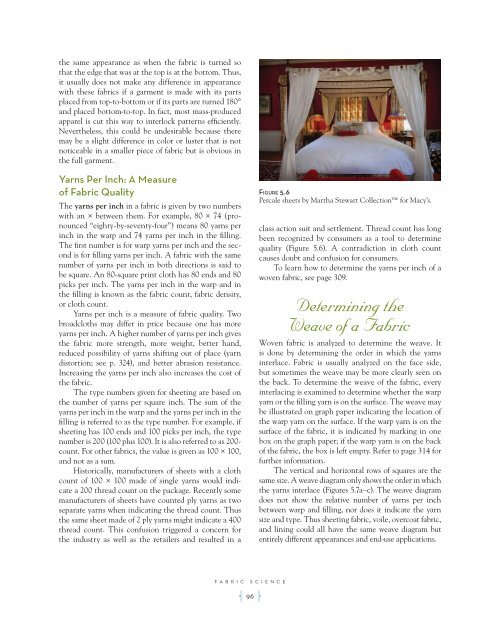

Figure 5.6<br />

Percale sheets by Martha Stewart Collection for Macy’s.<br />

class action suit and settlement. Thread count has long<br />

been recognized by consumers as a tool to determine<br />

quality (Figure 5.6). A contradiction in cloth count<br />

causes doubt and confusion for consumers.<br />

To learn how to determine the yarns per inch of a<br />

woven fabric, see page 309.<br />

Determining the<br />

Weave of a Fabric<br />

<strong>Woven</strong> fabric is analyzed to determine the weave. It<br />

is done by determining the order in which the yarns<br />

interlace. Fabric is usually analyzed on the face side,<br />

but sometimes the weave may be more clearly seen on<br />

the back. To determine the weave of the fabric, every<br />

interlacing is examined to determine whether the warp<br />

yarn or the filling yarn is on the surface. The weave may<br />

be illustrated on graph paper indicating the location of<br />

the warp yarn on the surface. If the warp yarn is on the<br />

surface of the fabric, it is indicated by marking in one<br />

box on the graph paper; if the warp yarn is on the back<br />

of the fabric, the box is left empty. Refer to page 314 for<br />

further information.<br />

The vertical and horizontal rows of squares are the<br />

same size. A weave diagram only shows the order in which<br />

the yarns interlace (Figures 5.7a–c). The weave diagram<br />

does not show the relative number of yarns per inch<br />

between warp and filling, nor does it indicate the yarn<br />

size and type. Thus sheeting fabric, voile, overcoat fabric,<br />

and lining could all have the same weave diagram but<br />

entirely different appearances and end-use applications.