Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

In filament yarn, the diameter is uniform and the<br />

filaments cannot slip when the yarn is pulled. Twist is<br />

not needed to hold the filaments in place. For these reasons,<br />

plying does not improve filament yarns as it does<br />

spun yarns. However, plying of filament yarns can be<br />

done to produce unique effects on novelty yarns and<br />

metallic yarns (see p. 80).<br />

Ply yarns require better-quality fiber, more labor,<br />

and special machinery. Because of this expense, ply<br />

yarns are more costly than singles. Thus, most fabrics<br />

are made of single yarns.<br />

Yarn Spinning<br />

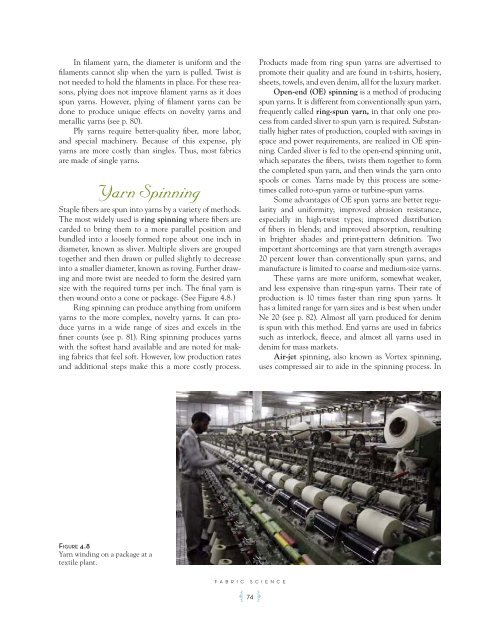

Staple fibers are spun into yarns by a variety of methods.<br />

The most widely used is ring spinning where fibers are<br />

carded to bring them to a more parallel position and<br />

bundled into a loosely formed rope about one inch in<br />

diameter, known as sliver. Multiple slivers are grouped<br />

together and then drawn or pulled slightly to decrease<br />

into a smaller diameter, known as roving. Further drawing<br />

and more twist are needed to form the desired yarn<br />

size with the required turns per inch. The final yarn is<br />

then wound onto a cone or package. (See Figure 4.8.)<br />

Ring spinning can produce anything from uniform<br />

yarns to the more complex, novelty yarns. It can produce<br />

yarns in a wide range of sizes and excels in the<br />

finer counts (see p. 81). Ring spinning produces yarns<br />

with the softest hand available and are noted for making<br />

fabrics that feel soft. However, low production rates<br />

and additional steps make this a more costly process.<br />

Figure 4.8<br />

Yarn winding on a package at a<br />

textile plant.<br />

FABRIC SCIENCE<br />

A 74 F<br />

Products made from ring spun yarns are advertised to<br />

promote their quality and are found in t-shirts, hosiery,<br />

sheets, towels, and even denim, all for the luxury market.<br />

Open-end (OE) spinning is a method of producing<br />

spun yarns. It is different from conventionally spun yarn,<br />

frequently called ring-spun yarn, in that only one process<br />

from carded sliver to spun yarn is required. Substantially<br />

higher rates of production, coupled with savings in<br />

space and power requirements, are realized in OE spinning.<br />

Carded sliver is fed to the open-end spinning unit,<br />

which separates the fibers, twists them together to form<br />

the completed spun yarn, and then winds the yarn onto<br />

spools or cones. Yarns made by this process are sometimes<br />

called roto-spun yarns or turbine-spun yarns.<br />

Some advantages of OE spun yarns are better regularity<br />

and uniformity; improved abrasion resistance,<br />

especially in high-twist types; improved distribution<br />

of fibers in blends; and improved absorption, resulting<br />

in brighter shades and print-pattern definition. Two<br />

important shortcomings are that yarn strength averages<br />

20 percent lower than conventionally spun yarns, and<br />

manufacture is limited to coarse and medium-size yarns.<br />

These yarns are more uniform, somewhat weaker,<br />

and less expensive than ring-spun yarns. Their rate of<br />

production is 10 times faster than ring spun yarns. It<br />

has a limited range for yarn sizes and is best when under<br />

Ne 20 (see p. 82). Almost all yarn produced for denim<br />

is spun with this method. End yarns are used in fabrics<br />

such as interlock, fleece, and almost all yarns used in<br />

denim for mass markets.<br />

Air-jet spinning, also known as Vortex spinning,<br />

uses compressed air to aide in the spinning process. In