You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Uses of Spun and Filament Yarns<br />

Some fabrics are made only of spun yarns, some of only<br />

filament yarns, and others of a combination of spun and<br />

filament yarns. Each type of yarn is best for certain uses.<br />

Spun yarns may provide warmth, softness, and lightness<br />

of weight and are, for example, ideal in fabrics for<br />

T-shirts, sweaters, and blankets. Filament yarns are better<br />

for items where smoothness and luster are desired<br />

because the yarns are finer, more uniform in diameter,<br />

and lustrous. Filament yarn fabrics can offer a smooth,<br />

uniform surface. They are used in linings because their<br />

smoothness makes it easier to slide into and out of<br />

garments. They are also used for the outer shell of ski<br />

jackets, in a tightly packed construction, to resist the<br />

penetration of wind.<br />

Yarn Twist<br />

Yarns are made by twisting together parallel or nearly<br />

parallel fibers. The amount of twist in a yarn is designated<br />

as the turns-per-inch (2.54 centimeters), or TPI,<br />

of the yarns. The TPI in a yarn has an important bearing<br />

on the appearance and durability of the yarn and<br />

the fabric that will be made from it.<br />

Spun yarns with relatively low twist (from 2 to 12<br />

TPI) are frequently called soft-twist yarns because the<br />

yarn is softer, fluffier, and more flexible. They are not as<br />

strong as spun yarns with high twist. Knitting yarns are<br />

usually soft twist.<br />

Spun yarns with relatively high TPI (20 to 30 TPI)<br />

are called hard-twist yarns. The higher twist causes<br />

them to be smoother, firmer, and kinkier than spun<br />

yarns with low twist. They are also stronger.<br />

Filament yarns usually have very low twist (½ to 1<br />

TPI). Twist in filament yarns does not increase strength<br />

but merely serves to keep the filaments in the yarn<br />

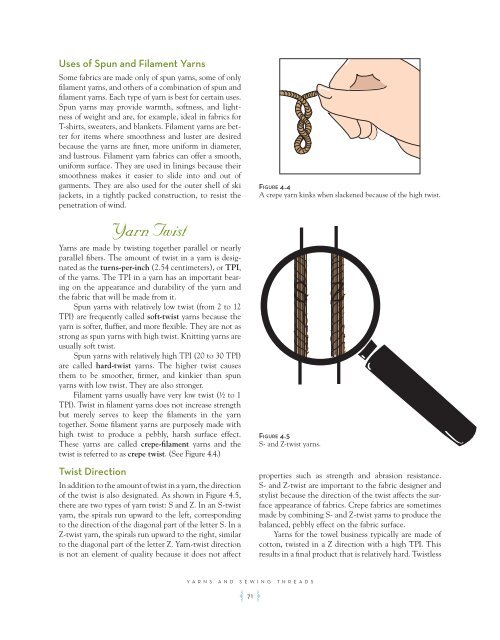

together. Some filament yarns are purposely made with<br />

high twist to produce a pebbly, harsh surface effect.<br />

These yarns are called crepe-filament yarns and the<br />

twist is referred to as crepe twist. (See Figure 4.4.)<br />

Twist Direction<br />

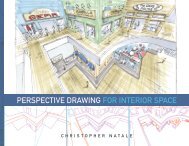

In addition to the amount of twist in a yarn, the direction<br />

of the twist is also designated. As shown in Figure 4.5,<br />

there are two types of yarn twist: S and Z. In an S-twist<br />

yarn, the spirals run upward to the left, corresponding<br />

to the direction of the diagonal part of the letter S. In a<br />

Z-twist yarn, the spirals run upward to the right, similar<br />

to the diagonal part of the letter Z. Yarn-twist direction<br />

is not an element of quality because it does not affect<br />

YARNS AND SEWING THREADS<br />

A 71 F<br />

Figure 4.4<br />

A crepe yarn kinks when slackened because of the high twist.<br />

Figure 4.5<br />

S- and Z-twist yarns.<br />

properties such as strength and abrasion resistance.<br />

S- and Z-twist are important to the fabric designer and<br />

stylist because the direction of the twist affects the surface<br />

appearance of fabrics. Crepe fabrics are sometimes<br />

made by combining S- and Z-twist yarns to produce the<br />

balanced, pebbly effect on the fabric surface.<br />

Yarns for the towel business typically are made of<br />

cotton, twisted in a Z direction with a high TPI. This<br />

results in a final product that is relatively hard. Twistless