You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Over 4,000 years ago, man created fabric through<br />

the use of a crude wood-framed loom. Typically<br />

this weaving device held yarns in an upright position as<br />

they were interlaced with one another by hand. Primeval<br />

man used this to make fabric to clothe and protect.<br />

As civilization began to develop, some woven fabric was<br />

used to indicate standing within the community. Eventually,<br />

royalty and religious figures used ornately woven<br />

fabric to indicate their stature. Looms were also used to<br />

depict stories in woven fabric, some of which are now<br />

highly valued (e.g., tapestry). Centuries later, as looms<br />

became more sophisticated and yarns smoother and<br />

finer, looms were used to create some of the world’s most<br />

intricate woven fabrics.<br />

<strong>Woven</strong> fabrics are made by interlacing two sets<br />

of yarns at right angles to each other. The length-wise<br />

yarns are known as warp yarns, or ends, and the widthwise<br />

yarns are known as filling yarns, or picks. The<br />

length-wise edges of the fabric are the selvages. The selvage<br />

is usually easily distinguishable from the rest of the<br />

material. (See p. 93.)<br />

Grain indicates a direction parallel to either the<br />

warp or filling yarns. The term on grain is used if a<br />

fabric has been cut parallel to either the warp or filling<br />

yarns. A direction not parallel to either of these yarns is<br />

called off grain, or bias. Fabric cut off grain results in a<br />

skewed portion of the textile product (e.g., pants leg or<br />

drapery). <strong>Woven</strong> fabrics elongates most in a direction<br />

that is 45° to both sets of yarns. The reason for this is<br />

that there is maximum yarn bending and shifting from<br />

the pulling force being exerted. Pulling that is on grain<br />

results in only a slight yarn extension, with the least<br />

amount usually in the warp direction.<br />

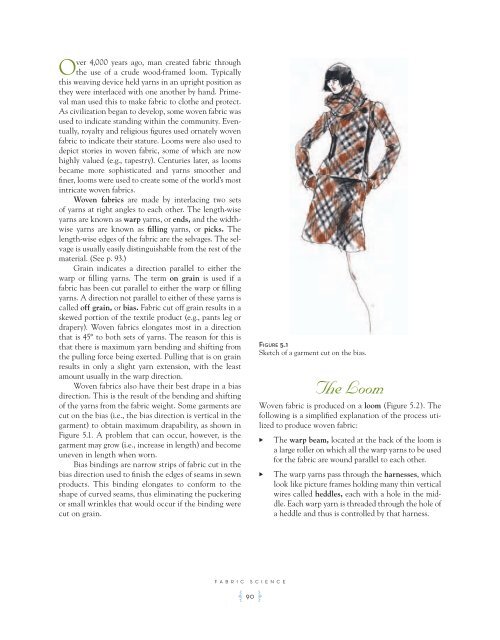

<strong>Woven</strong> fabrics also have their best drape in a bias<br />

direction. This is the result of the bending and shifting<br />

of the yarns from the fabric weight. Some garments are<br />

cut on the bias (i.e., the bias direction is vertical in the<br />

garment) to obtain maximum drapability, as shown in<br />

Figure 5.1. A problem that can occur, however, is the<br />

garment may grow (i.e., increase in length) and become<br />

uneven in length when worn.<br />

Bias bindings are narrow strips of fabric cut in the<br />

bias direction used to finish the edges of seams in sewn<br />

products. This binding elongates to conform to the<br />

shape of curved seams, thus eliminating the puckering<br />

or small wrinkles that would occur if the binding were<br />

cut on grain.<br />

FABRIC SCIENCE<br />

A 90 F<br />

Figure 5.1<br />

Sketch of a garment cut on the bias.<br />

The Loom<br />

<strong>Woven</strong> fabric is produced on a loom (Figure 5.2). The<br />

following is a simplified explanation of the process utilized<br />

to produce woven fabric:<br />

u The warp beam, located at the back of the loom is<br />

a large roller on which all the warp yarns to be used<br />

for the fabric are wound parallel to each other.<br />

u The warp yarns pass through the harnesses, which<br />

look like picture frames holding many thin vertical<br />

wires called heddles, each with a hole in the middle.<br />

Each warp yarn is threaded through the hole of<br />

a heddle and thus is controlled by that harness.