SIMOTION software - Gregbotos.com

SIMOTION software - Gregbotos.com

SIMOTION software - Gregbotos.com

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

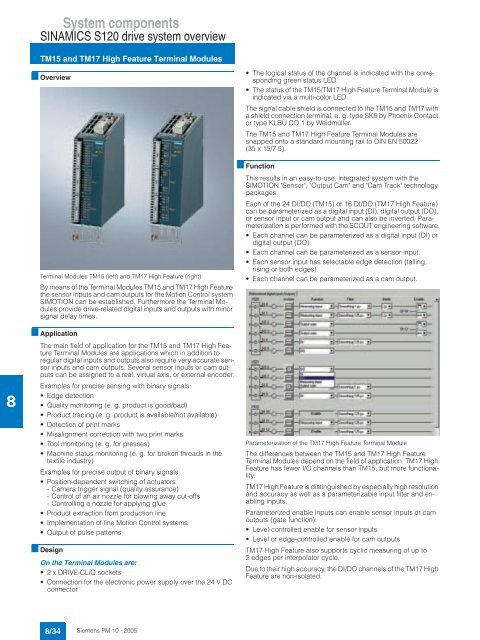

System <strong>com</strong>ponentsSINAMICS S120 drive system overviewTM15 and TM17 High Feature Terminal Modules■ Overview• The logical status of the channel is indicated with the correspondinggreen status LED.• The status of the TM15/TM17 High Feature Terminal Module isindicated via a multi-color LED.The signal cable shield is connected to the TM15 and TM17 witha shield connection terminal, e. g. type SK8 by Phoenix Contactor type KLBÜ CO 1 by Weidmüller.The TM15 and TM17 High Feature Terminal Modules aresnapped onto a standard mounting rail to DIN EN 50022(35 x 15/7.5).Terminal Modules TM15 (left) and TM17 High Feature (right)By means of the Terminal Modules TM15 and TM17 High Featurethe sensor inputs and cam outputs for the Motion Control system<strong>SIMOTION</strong> can be established. Furthermore the Terminal Modulesprovide drive-related digital inputs and outputs with minorsignal delay times.■ FunctionThis results in an easy-to-use, integrated system with the<strong>SIMOTION</strong> "Sensor", "Output Cam" and "Cam Track" technologypackages.Each of the 24 DI/DO (TM15) or 16 DI/DO (TM17 High Feature)can be parameterized as a digital input (DI), digital output (DO),or sensor input or cam output and can also be inverted. Parameterizationis performed with the SCOUT engineering <strong>software</strong>.• Each channel can be parameterized as a digital input (DI) ordigital output (DO).• Each channel can be parameterized as a sensor input.• Each sensor input has selectable edge detection (falling,rising or both edges).• Each channel can be parameterized as a cam output.8■ ApplicationThe main field of application for the TM15 and TM17 High FeatureTerminal Modules are applications which in addition toregular digital inputs and outputs also require very accurate sensorinputs and cam outputs. Several sensor inputs or cam outputscan be assigned to a real, virtual axis, or external encoder.Examples for precise sensing with binary signals:• Edge detection• Quality monitoring (e. g. product is good/bad)• Product tracing (e. g. product is available/not available)• Detection of print marks• Misalignment correction with two print marks• Tool monitoring (e. g. for presses)• Machine status monitoring (e. g. for broken threads in thetextile industry)Examples for precise output of binary signals• Position-dependent switching of actuators- Camera trigger signal (quality assurance)- Control of an air nozzle for blowing away cut-offs- Controlling a nozzle for applying glue• Product extraction from production line• Implementation of line Motion Control systems• Output of pulse patterns■ DesignOn the Terminal Modules are:• 2 x DRIVE-CLiQ sockets• Connection for the electronic power supply over the 24 V DCconnectorParameterization of the TM17 High Feature Terminal ModuleThe differences between the TM15 and TM17 High FeatureTerminal Modules depend on the field of application. TM17 HighFeature has fewer I/O channels than TM15, but more functionality.TM17 High Feature is distinguished by especially high resolutionand accuracy as well as a parameterizable input filter and enablinginputs.Parameterized enable inputs can enable sensor inputs or camoutputs (gate function):• Level-controlled enable for sensor inputs• Level or edge-controlled enable for cam outputsTM17 High Feature also supports cyclic measuring of up to2 edges per interpolator cycle.Due to their high accuracy, the DI/DO channels of the TM17 HighFeature are non-isolated.8/34 Siemens PM 10 · 2005