SIMOTION software - Gregbotos.com

SIMOTION software - Gregbotos.com

SIMOTION software - Gregbotos.com

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

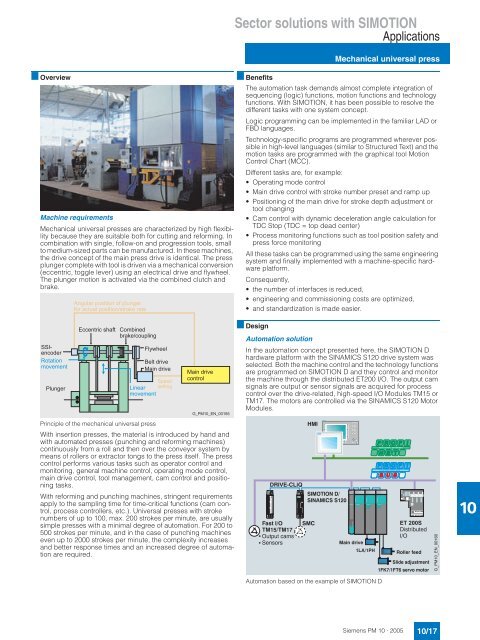

L1+ TM 15DI/0 0 RDYDI/0 1DI/0 2DI/0 3X520DI/0 4DI/0 5DI/0 6DI/0 7M1L2+DI/0 8DI/0 9DI/0 10DI/0 11X521DI/0 12DI/0 13DI/0 14DI/0 15M2L3+DI/0 16DI/0 17DI/0 18DI/0 19X520DI/0 20DI/0 21DI/0 22DI/0 23M3■ OverviewMachine requirementsMechanical universal presses are characterized by high flexibilitybecause they are suitable both for cutting and reforming. In<strong>com</strong>bination with single, follow-on and progression tools, smallto medium-sized parts can be manufactured. In these machines,the drive concept of the main press drive is identical. The pressplunger <strong>com</strong>plete with tool is driven via a mechanical conversion(eccentric, toggle lever) using an electrical drive and flywheel.The plunger motion is activated via the <strong>com</strong>bined clutch andbrake.Angular position of plungerfor actual position/stroke rateSector solutions with <strong>SIMOTION</strong>ApplicationsMechanical universal press■ BenefitsThe automation task demands almost <strong>com</strong>plete integration ofsequencing (logic) functions, motion functions and technologyfunctions. With <strong>SIMOTION</strong>, it has been possible to resolve thedifferent tasks with one system concept.Logic programming can be implemented in the familiar LAD orFBD languages.Technology-specific programs are programmed wherever possiblein high-level languages (similar to Structured Text) and themotion tasks are programmed with the graphical tool MotionControl Chart (MCC).Different tasks are, for example:• Operating mode control• Main drive control with stroke number preset and ramp up• Positioning of the main drive for stroke depth adjustment ortool changing• Cam control with dynamic deceleration angle calculation forTDC Stop (TDC = top dead center)• Process monitoring functions such as tool position safety andpress force monitoringAll these tasks can be programmed using the same engineeringsystem and finally implemented with a machine-specific hardwareplatform.Consequently,• the number of interfaces is reduced,• engineering and <strong>com</strong>missioning costs are optimized,• and standardization is made easier.SSIencoderRotationmovementPlungerEccentric shaft Combinedbrake/couplingFlywheelBelt driveMain driveSpeedLinear settingmovementMain drivecontrolG_PM10_EN_00155Principle of the mechanical universal pressWith insertion presses, the material is introduced by hand andwith automated presses (punching and reforming machines)continuously from a roll and then over the conveyor system bymeans of rollers or extractor tongs to the press itself. The presscontrol performs various tasks such as operator control andmonitoring, general machine control, operating mode control,main drive control, tool management, cam control and positioningtasks.With reforming and punching machines, stringent requirementsapply to the sampling time for time-critical functions (cam control,process controllers, etc.). Universal presses with strokenumbers of up to 100, max. 200 strokes per minute, are usuallysimple presses with a minimal degree of automation. For 200 to500 strokes per minute, and in the case of punching machineseven up to 2000 strokes per minute, the <strong>com</strong>plexity increasesand better response times and an increased degree of automationare required.■ DesignAutomation solutionIn the automation concept presented here, the <strong>SIMOTION</strong> Dhardware platform with the SINAMICS S120 drive system wasselected. Both the machine control and the technology functionsare programmed on <strong>SIMOTION</strong> D and they control and monitorthe machine through the distributed ET200 I/O. The output camsignals are output or sensor signals are acquired for processcontrol over the drive-related, high-speed I/O Modules TM15 orTM17. The motors are controlled via the SINAMICS S120 MotorModules.DRIVE-CLiQFast I/OTM15/TM17Output camsSensorsHMI<strong>SIMOTION</strong> D/SINAMICS S120SMCMain drive1LA/1PHET 200SDistributedI/ORoller feedSlide adjustment1FK7/1FT6 servo motorG_PM10_EN_0016010Automation based on the example of <strong>SIMOTION</strong> DSiemens PM 10 · 200510/17