SIMOTION software - Gregbotos.com

SIMOTION software - Gregbotos.com

SIMOTION software - Gregbotos.com

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

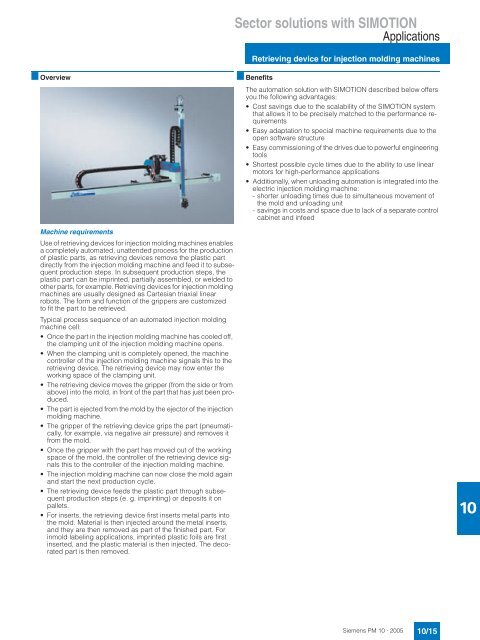

Sector solutions with <strong>SIMOTION</strong>ApplicationsRetrieving device for injection molding machines■ Overview■ BenefitsThe automation solution with <strong>SIMOTION</strong> described below offersyou the following advantages:• Cost savings due to the scalability of the <strong>SIMOTION</strong> systemthat allows it to be precisely matched to the performance requirements• Easy adaptation to special machine requirements due to theopen <strong>software</strong> structure• Easy <strong>com</strong>missioning of the drives due to powerful engineeringtools• Shortest possible cycle times due to the ability to use linearmotors for high-performance applications• Additionally, when unloading automation is integrated into theelectric injection molding machine:- shorter unloading times due to simultaneous movement ofthe mold and unloading unit- savings in costs and space due to lack of a separate controlcabinet and infeedMachine requirementsUse of retrieving devices for injection molding machines enablesa <strong>com</strong>pletely automated, unattended process for the productionof plastic parts, as retrieving devices remove the plastic partdirectly from the injection molding machine and feed it to subsequentproduction steps. In subsequent production steps, theplastic part can be imprinted, partially assembled, or welded toother parts, for example. Retrieving devices for injection moldingmachines are usually designed as Cartesian triaxial linearrobots. The form and function of the grippers are customizedto fit the part to be retrieved.Typical process sequence of an automated injection moldingmachine cell:• Once the part in the injection molding machine has cooled off,the clamping unit of the injection molding machine opens.• When the clamping unit is <strong>com</strong>pletely opened, the machinecontroller of the injection molding machine signals this to theretrieving device. The retrieving device may now enter theworking space of the clamping unit.• The retrieving device moves the gripper (from the side or fromabove) into the mold, in front of the part that has just been produced.• The part is ejected from the mold by the ejector of the injectionmolding machine.• The gripper of the retrieving device grips the part (pneumatically,for example, via negative air pressure) and removes itfrom the mold.• Once the gripper with the part has moved out of the workingspace of the mold, the controller of the retrieving device signalsthis to the controller of the injection molding machine.• The injection molding machine can now close the mold againand start the next production cycle.• The retrieving device feeds the plastic part through subsequentproduction steps (e. g. imprinting) or deposits it onpallets.• For inserts, the retrieving device first inserts metal parts intothe mold. Material is then injected around the metal inserts,and they are then removed as part of the finished part. Forinmold labeling applications, imprinted plastic foils are firstinserted, and the plastic material is then injected. The decoratedpart is then removed.10Siemens PM 10 · 200510/15