SIMOTION software - Gregbotos.com

SIMOTION software - Gregbotos.com

SIMOTION software - Gregbotos.com

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

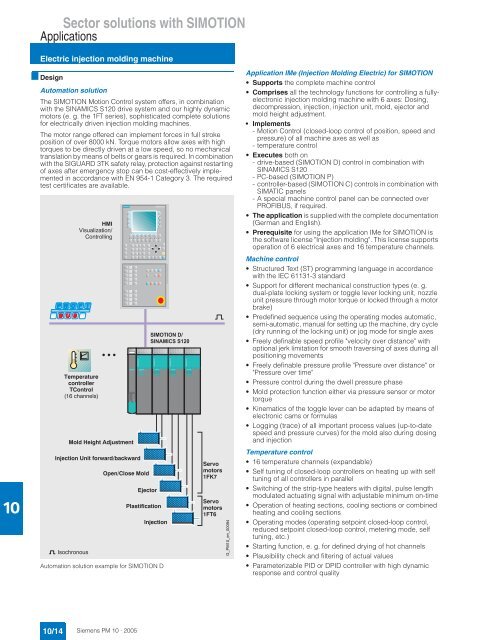

Sector solutions with <strong>SIMOTION</strong>ApplicationsElectric injection molding machine10■ DesignAutomation solutionThe <strong>SIMOTION</strong> Motion Control system offers, in <strong>com</strong>binationwith the SINAMICS S120 drive system and our highly dynamicmotors (e. g. the 1FT series), sophisticated <strong>com</strong>plete solutionsfor electrically driven injection molding machines.The motor range offered can implement forces in full strokeposition of over 8000 kN. Torque motors allow axes with hightorques to be directly driven at a low speed, so no mechanicaltranslation by means of belts or gears is required. In <strong>com</strong>binationwith the SIGUARD 3TK safety relay, protection against restartingof axes after emergency stop can be cost-effectively implementedin accordance with EN 954-1 Category 3. The requiredtest certificates are available.°CTemperaturecontrollerTControl(16 channels)•••Mold Height AdjustmentInjection Unit forward/backwardIsochronousHMIVisualization/ControllingOpen/Close MoldEjectorPlastificationAutomation solution example for <strong>SIMOTION</strong> D<strong>SIMOTION</strong> D/SINAMICS S120InjectionServomotors1FK7Servomotors1FT6G_PM10_en_00094Application IMe (Injection Molding Electric) for <strong>SIMOTION</strong>• Supports the <strong>com</strong>plete machine control• Comprises all the technology functions for controlling a fullyelectronicinjection molding machine with 6 axes: Dosing,de<strong>com</strong>pression, injection, injection unit, mold, ejector andmold height adjustment.• Implements- Motion Control (closed-loop control of position, speed andpressure) of all machine axes as well as- temperature control• Executes both on- drive-based (<strong>SIMOTION</strong> D) control in <strong>com</strong>bination withSINAMICS S120- PC-based (<strong>SIMOTION</strong> P)- controller-based (<strong>SIMOTION</strong> C) controls in <strong>com</strong>bination withSIMATIC panels- A special machine control panel can be connected overPROFIBUS, if required.• The application is supplied with the <strong>com</strong>plete documentation(German and English).• Prerequisite for using the application IMe for <strong>SIMOTION</strong> isthe <strong>software</strong> license "Injection molding". This license supportsoperation of 6 electrical axes and 16 temperature channels.Machine control• Structured Text (ST) programming language in accordancewith the IEC 61131-3 standard• Support for different mechanical construction types (e. g.dual-plate locking system or toggle lever locking unit, nozzleunit pressure through motor torque or locked through a motorbrake)• Predefined sequence using the operating modes automatic,semi-automatic, manual for setting up the machine, dry cycle(dry running of the locking unit) or jog mode for single axes• Freely definable speed profile "velocity over distance" withoptional jerk limitation for smooth traversing of axes during allpositioning movements• Freely definable pressure profile "Pressure over distance" or"Pressure over time"• Pressure control during the dwell pressure phase• Mold protection function either via pressure sensor or motortorque• Kinematics of the toggle lever can be adapted by means ofelectronic cams or formulas• Logging (trace) of all important process values (up-to-datespeed and pressure curves) for the mold also during dosingand injectionTemperature control• 16 temperature channels (expandable)• Self tuning of closed-loop controllers on heating up with selftuning of all controllers in parallel• Switching of the strip-type heaters with digital, pulse lengthmodulated actuating signal with adjustable minimum on-time• Operation of heating sections, cooling sections or <strong>com</strong>binedheating and cooling sections• Operating modes (operating setpoint closed-loop control,reduced setpoint closed-loop control, metering mode, selftuning, etc.)• Starting function, e. g. for defined drying of hot channels• Plausibility check and filtering of actual values• Parameterizable PID or DPID controller with high dynamicresponse and control quality10/14 Siemens PM 10 · 2005