SIMOTION software - Gregbotos.com

SIMOTION software - Gregbotos.com

SIMOTION software - Gregbotos.com

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

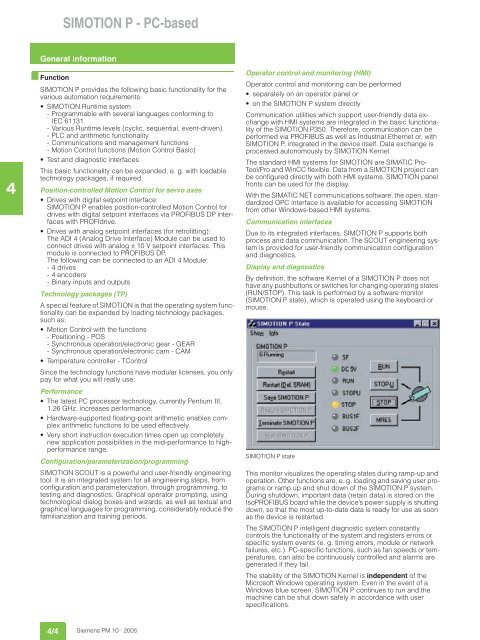

<strong>SIMOTION</strong> P - PC-based4General information■ Function<strong>SIMOTION</strong> P provides the following basic functionality for thevarious automation requirements:• <strong>SIMOTION</strong> Runtime system- Programmable with several languages conforming toIEC 61131- Various Runtime levels (cyclic, sequential, event-driven)- PLC and arithmetic functionality- Communications and management functions- Motion Control functions (Motion Control Basic)• Test and diagnostic interfacesThis basic functionality can be expanded, e. g. with loadabletechnology packages, if required.Position-controlled Motion Control for servo axes• Drives with digital setpoint interface:<strong>SIMOTION</strong> P enables position-controlled Motion Control fordrives with digital setpoint interfaces via PROFIBUS DP interfaceswith PROFIdrive.• Drives with analog setpoint interfaces (for retrofitting):The ADI 4 (Analog Drive Interface) Module can be used toconnect drives with analog ± 10 V setpoint interfaces. Thismodule is connected to PROFIBUS DP.The following can be connected to an ADI 4 Module:- 4 drives- 4 encoders- Binary inputs and outputsTechnology packages (TP)A special feature of <strong>SIMOTION</strong> is that the operating system functionalitycan be expanded by loading technology packages,such as:• Motion Control with the functions- Positioning - POS- Synchronous operation/electronic gear - GEAR- Synchronous operation/electronic cam - CAM• Temperature controller - TControlSince the technology functions have modular licenses, you onlypay for what you will really use.Performance• The latest PC processor technology, currently Pentium III,1.26 GHz, increases performance.• Hardware-supported floating-point arithmetic enables <strong>com</strong>plexarithmetic functions to be used effectively.• Very short instruction execution times open up <strong>com</strong>pletelynew application possibilities in the mid-performance to highperformancerange.Configuration/parameterization/programming<strong>SIMOTION</strong> SCOUT is a powerful and user-friendly engineeringtool. It is an integrated system for all engineering steps, fromconfiguration and parameterization, through programming, totesting and diagnostics. Graphical operator prompting, usingtechnological dialog boxes and wizards, as well as textual andgraphical languages for programming, considerably reduce thefamiliarization and training periods.Operator control and monitoring (HMI)Operator control and monitoring can be performed• separately on an operator panel or• on the <strong>SIMOTION</strong> P system directlyCommunication utilities which support user-friendly data exchangewith HMI systems are integrated in the basic functionalityof the <strong>SIMOTION</strong> P350. Therefore, <strong>com</strong>munication can beperformed via PROFIBUS as well as Industrial Ethernet or, with<strong>SIMOTION</strong> P, integrated in the device itself. Data exchange isprocessed autonomously by <strong>SIMOTION</strong> Kernel.The standard HMI systems for <strong>SIMOTION</strong> are SIMATIC Pro-Tool/Pro and WinCC flexible. Data from a <strong>SIMOTION</strong> project canbe configured directly with both HMI systems. <strong>SIMOTION</strong> panelfronts can be used for the display.With the SIMATIC NET <strong>com</strong>munications <strong>software</strong>, the open, standardizedOPC interface is available for accessing <strong>SIMOTION</strong>from other Windows-based HMI systems.Communication interfacesDue to its integrated interfaces, <strong>SIMOTION</strong> P supports bothprocess and data <strong>com</strong>munication. The SCOUT engineering systemis provided for user-friendly <strong>com</strong>munication configurationand diagnostics.Display and diagnosticsBy definition, the <strong>software</strong> Kernel of a <strong>SIMOTION</strong> P does nothave any pushbuttons or switches for changing operating states(RUN/STOP). This task is performed by a <strong>software</strong> monitor(<strong>SIMOTION</strong> P state), which is operated using the keyboard ormouse.<strong>SIMOTION</strong> P stateThis monitor visualizes the operating states during ramp-up andoperation. Other functions are, e. g. loading and saving user programsor ramp up and shut down of the <strong>SIMOTION</strong> P system.During shutdown, important data (retain data) is stored on theIsoPROFIBUS board while the device’s power supply is shuttingdown, so that the most up-to-date data is ready for use as soonas the device is restarted.The <strong>SIMOTION</strong> P intelligent diagnostic system constantlycontrols the functionality of the system and registers errors orspecific system events (e. g. timing errors, module or networkfailures, etc.). PC-specific functions, such as fan speeds or temperatures,can also be continuously controlled and alarms aregenerated if they fail.The stability of the <strong>SIMOTION</strong> Kernel is independent of theMicrosoft Windows operating system. Even in the event of aWindows blue screen, <strong>SIMOTION</strong> P continues to run and themachine can be shut down safely in accordance with userspecifications.4/4 Siemens PM 10 · 2005