FM 1-506 Fundamentals of Aircraft Power Plants ... - Survival Books

FM 1-506 Fundamentals of Aircraft Power Plants ... - Survival Books

FM 1-506 Fundamentals of Aircraft Power Plants ... - Survival Books

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

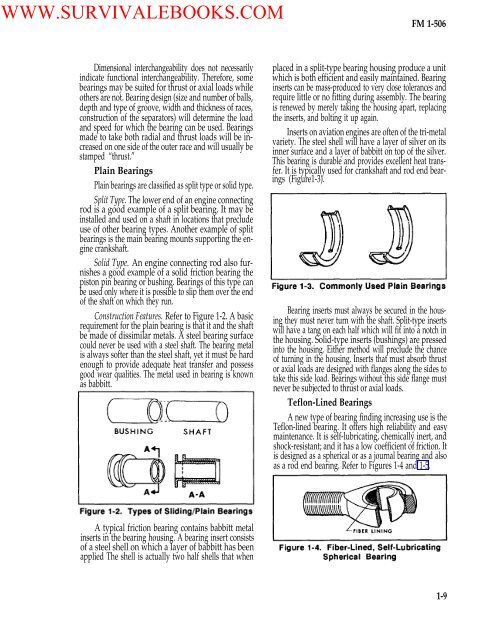

WWW.SURVIVALEBOOKS.COM<strong>FM</strong> 1-<strong>506</strong>Dimensional interchangeability does not necessarilyindicate functional interchangeability. Therefore, somebearings may be suited for thrust or axial loads whileothers are not. Bearing design (size and number <strong>of</strong> balls,depth and type <strong>of</strong> groove, width and thickness <strong>of</strong> races,construction <strong>of</strong> the separators) will determine the loadand speed for which the bearing can be used. Bearingsmade to take both radial and thrust loads will be increasedon one side <strong>of</strong> the outer race and will usually bestamped “thrust.”Plain BearingsPlain bearings are classified as split type or solid type.Split Type. The lower end <strong>of</strong> an engine connectingrod is a good example <strong>of</strong> a split bearing. It may beinstalled and used on a shaft in locations that precludeuse <strong>of</strong> other bearing types. Another example <strong>of</strong> splitbearings is the main bearing mounts supporting the enginecrankshaft.Solid Type. An engine connecting rod also furnishesa good example <strong>of</strong> a solid friction bearing thepiston pin bearing or bushing. Bearings <strong>of</strong> this type canbe used only where it is possible to slip them over the end<strong>of</strong> the shaft on which they run.Construction Features. Refer to Figure 1-2. A basicrequirement for the plain bearing is that it and the shaftbe made <strong>of</strong> dissimilar metals. A steel bearing surfacecould never be used with a steel shaft. The bearing metalis always s<strong>of</strong>ter than the steel shaft, yet it must be hardenough to provide adequate heat transfer and possessgood wear qualities. The metal used in bearing is knownas babbitt.placed in a split-type bearing housing produce a unitwhich is both efficient and easily maintained. Bearinginserts can be mass-produced to very close tolerances andrequire little or no fitting during assembly. The bearingis renewed by merely taking the housing apart, replacingthe inserts, and bolting it up again.Inserts on aviation engines are <strong>of</strong>ten <strong>of</strong> the tri-metalvariety. The steel shell will have a layer <strong>of</strong> silver on itsinner surface and a layer <strong>of</strong> babbitt on top <strong>of</strong> the silver.This bearing is durable and provides excellent heat transfer.It is typically used for crankshaft and rod end bearings(Figure1-3).Bearing inserts must always be secured in the housingthey must never turn with the shaft. Split-type insertswill have a tang on each half which will fit into a notch inthe housing. Solid-type inserts (bushings) are pressedinto the housing. Either method will preclude the chance<strong>of</strong> turning in the housing. Inserts that must absorb thrustor axial loads are designed with flanges along the sides totake this side load. Bearings without this side flange mustnever be subjected to thrust or axial loads.Teflon-Lined BearingsA new type <strong>of</strong> bearing finding increasing use is theTeflon-lined bearing. It <strong>of</strong>fers high reliability and easymaintenance. It is self-lubricating, chemically inert, andshock-resistant; and it has a low coefficient <strong>of</strong> friction. Itis designed as a spherical or as a journal bearing and alsoas a rod end bearing. Refer to Figures 1-4 and 1-5.A typical friction bearing contains babbitt metalinserts in the bearing housing. A bearing insert consists<strong>of</strong> a steel shell on which a layer <strong>of</strong> babbitt has beenapplied The shell is actually two half shells that when1-9