WWW.SURVIVALEBOOKS.COM<strong>FM</strong> 1-<strong>506</strong>Thermal shock resistance—the ability <strong>of</strong> a metalto withstand extreme changes in temperature inshort periods <strong>of</strong> time.Hardness—the ability <strong>of</strong> a metal to resistabrasion penetration cutting action or permanentdistortion. Hardness may be increasedby working the metal or by heat treatment.Alloying—the combining <strong>of</strong> metals in their moltenstate to create desirable qualities or reduceor eliminate undesirable qualities.Common metal working terms include the following:Casting—a process whereby molten metalsolidifies in a mold.Forging—a process <strong>of</strong> plastic deformationunder pressure that may be slowly or quicklyappliedElectrochemical machining (ECM)—controlledhigh-speed deplating using a shaped tool(cathode), an electricity-conducting solutionand the workpiece (anode).Machining—any process where metal is formedby cuttin,- hot or cold rolling pinching, punching,grinding, or by laser beams.Extrusion—pushing through a die to formvarious cross-sectional shapes.Welding—a process <strong>of</strong> fusing two pieces <strong>of</strong>metal together by locally melting part <strong>of</strong> thematerial by arc welders, plasmas, lasers, orelectron beams.Pressing—a process <strong>of</strong> blending, pressing,sintering (fusing the power particles togetherthrough heat), and coining metals out <strong>of</strong> prealloyedpowders.Protective finish and surface treatment—includesplating by electrical and chemicalprocesses ceramic coatings, or painting. Surfacetreatments for increased wear may take theform <strong>of</strong> nitriding, cyaniding, carburizing, diffusioncoating and flame plating.Shot peening—a plastic flow or stretching <strong>of</strong> ametal’s surface by a rain <strong>of</strong> round metallic shotthrown at high velocity. Shot peening alsoserves to work-harden metals, especiallyaluminum alloy.Heat treatment—a series <strong>of</strong> operations involvingthe controlled heating and cooling <strong>of</strong> metalsin the solid state. Its purposes is to change amechanical property or combination <strong>of</strong> propertiesso that the metal will be more useful,serviceable, and safe for a specific purpose. Itincludes normalizing annealing stress relievingtemperingand hardening.Inspection (strictly speaking not a part <strong>of</strong> themetalworking process but integrally associatedwith it) – includes magnetic particle and dyepenetrant inspection, X-ray inspection dimensionaland visual inspection, and inspection bydevices using sound, light, and air.Heat Ranges <strong>of</strong> MetalsThe operating conditions inside a gas turbine enginevary considerably, and metals differ in their ability tosatisfactorily meet these conditions.Aluminum Alloys. Aluminum and its alloys areused in temperature ranges up to 500ºF. With low densityand good strength-to-weight ratios, aluminum forgingsand castings are used extensively for centrifugal compressorwheels and housings, air inlet sections, accessorysections, and for the accessories themselves.Magnesium Alloys. Magnesium is the world’slightest structural metal. Aluminum is 15 times heavier,titanium 25 times heavier, steel 4 times heavier, andcopper and nickel alloys are 5 times heavier. Magnesiumis combined with small amounts <strong>of</strong> certain other metals,including aluminum, manganese, zinc, zirconium,thorium, and others, to obtain the strong lightweightalloys needed for structural purposes.Titanium Alloys. Titanium and its alloys are usedfor axial-flow compressor wheels, blades, and otherforged components in many large, high-performanceengines. Titanium combines high strength with low densityand is suitable for applications up to 100ºF.Steel Alloys. This group includes high-chromium,molybdenum, high-nickel, and iron-base alloys in additionto low-alloy steels. Because <strong>of</strong> the relatively lowmaterial cost, ease <strong>of</strong> fabrication, and good mechanicalproperties, low-alloy steels are commonly used for bothrotating and static engine components such as compressorrotor blades, wheels, spacers, stator vanes and structuralmembers. Low-alloy steels can be heat-treated andcan withstand temperatures up to 100°F. High nickelchromiumiron-base alloys can be used up to 1250ºF.Nickel-Base Alloys. Nickel-base alloys are some <strong>of</strong>the best metals for use between 1200ºF and 1800ºF. Mostcontain little or no iron. They develop high-temperaturestrength by age hardening and are chacterized by longtimecreep-rupture strength as well as high ultimate andyield strength combined with good ductility. Many <strong>of</strong>these materials, originally developed for turbine bucket3-25

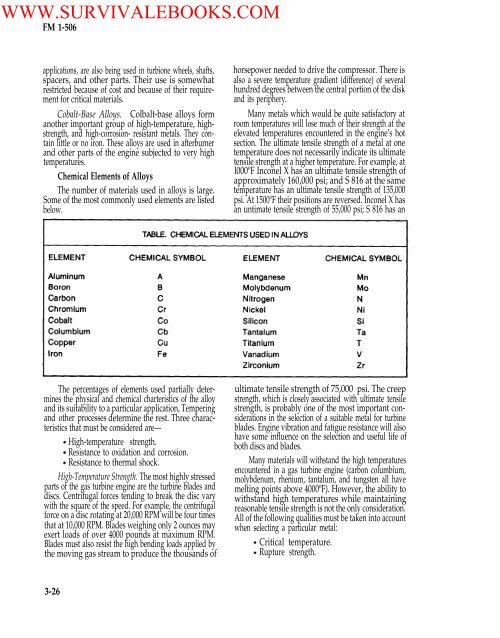

WWW.SURVIVALEBOOKS.COM<strong>FM</strong> 1-<strong>506</strong>applications, are also being used in turbione wheels, shafts,spacers, and other parts. Their use is somewhatrestricted because <strong>of</strong> cost and because <strong>of</strong> their requirementfor critical materials.Cobalt-Base Alloys. Colbalt-base alloys formanother important group <strong>of</strong> high-temperature, highstrength,and high-corrosion- resistant metals. They containlittle or no iron. These alloys are used in afterburnerand other parts <strong>of</strong> the engine subjected to very hightemperatures.Chemical Elements <strong>of</strong> AlloysThe number <strong>of</strong> materials used in alloys is large.Some <strong>of</strong> the most commonly used elements are listedbelow.horsepower needed to drive the compressor. There isalso a severe temperature gradient (difference) <strong>of</strong> severalhundred degrees between the central portion <strong>of</strong> the diskand its periphery.Many metals which would be quite satisfactory atroom temperatures will lose much <strong>of</strong> their strength at theelevated temperatures encountered in the engine’s hotsection. The ultimate tensile strength <strong>of</strong> a metal at onetemperature does not necessarily indicate its ultimatetensile strength at a higher temperature. For example, atl000ºF Inconel X has an ultimate tensile strength <strong>of</strong>approximately 160,000 psi; and S 816 at the sametemperature has an ultimate tensile strength <strong>of</strong> 135,000psi. At 1500ºF their positions are reversed. Inconel X hasan untimate tensile strength <strong>of</strong> 55,000 psi; S 816 has anThe percentages <strong>of</strong> elements used partially determinesthe physical and chemical charteristics <strong>of</strong> the alloyand its suitability to a particular application, Temperingand other processes determine the rest. Three characteristicsthat must be considered are—High-temperature strength.Resistance to oxidation and corrosion.Resistance to thermal shock.High-Temperature Strength. The most highly stressedparts <strong>of</strong> the gas turbine engine are the turbine blades anddiscs. Centrifugal forces tending to break the disc varywith the square <strong>of</strong> the speed. For example, the centrifugalforce on a disc rotating at 20,000 RPM will be four timesthat at 10,000 RPM. Blades weighing only 2 ounces mayexert loads <strong>of</strong> over 4000 pounds at maximum RPM.Blades must also resist the high bending loads applied bythe moving gas stream to produce the thousands <strong>of</strong>ultimate tensile strength <strong>of</strong> 75,000 psi. The creepstrength, which is closely associated with ultimate tensilestrength, is probably one <strong>of</strong> the most important considerationsin the selection <strong>of</strong> a suitable metal for turbineblades. Engine vibration and fatigue resistance will alsohave some influence on the selection and useful life <strong>of</strong>both discs and blades.Many materials will withstand the high temperaturesencountered in a gas turbine engine (carbon columbium,molybdenum, rhenium, tantalum, and tungsten all havemelting points above 4000ºF). However, the ability towithstand high temperatures while maintainingreasonable tensile strength is not the only consideration.All <strong>of</strong> the following qualities must be taken into accountwhen selecting a particular metal:Critical temperature.Rupture strength.3-26