FM 1-506 Fundamentals of Aircraft Power Plants ... - Survival Books

FM 1-506 Fundamentals of Aircraft Power Plants ... - Survival Books

FM 1-506 Fundamentals of Aircraft Power Plants ... - Survival Books

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

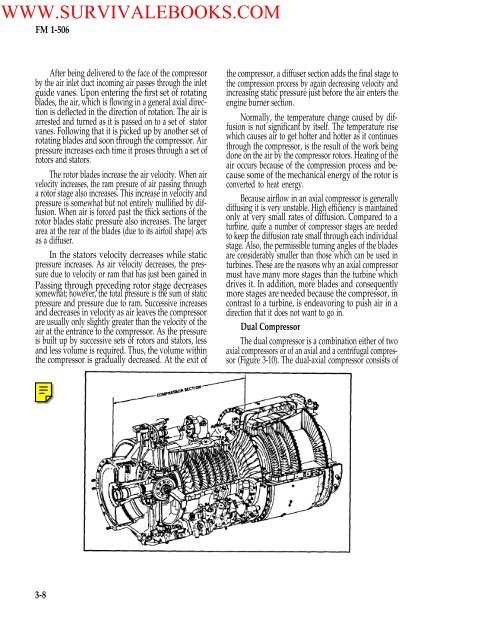

WWW.SURVIVALEBOOKS.COM<strong>FM</strong> 1-<strong>506</strong>After being delivered to the face <strong>of</strong> the compressorby the air inlet duct incoming air passes through the inletguide vanes. Upon entering the first set <strong>of</strong> rotatingblades, the air, which is flowing in a general axial directionis deflected in the direction <strong>of</strong> rotation. The air isarrested and turned as it is passed on to a set <strong>of</strong> statorvanes. Following that it is picked up by another set <strong>of</strong>rotating blades and soon through the compressor. Airpressure increases each time it proses through a set <strong>of</strong>rotors and stators.The rotor blades increase the air velocity. When airvelocity increases, the ram presure <strong>of</strong> air passing througha rotor stage also increases. This increase in velocity andpressure is somewhat but not entirely mullified by diffusion.When air is forced past the thick sections <strong>of</strong> therotor blades static pressure also increases. The largerarea at the rear <strong>of</strong> the blades (due to its airfoil shape) actsas a diffuser.In the stators velocity decreases while staticpressure increases. As air velocity decreases, the pressuredue to velocity or ram that has just been gained inPassing through preceding rotor stage decreasessomewhat; however, the total pressure is the sum <strong>of</strong> staticpressure and pressure due to ram. Successive increasesand decreases in velocity as air leaves the compressorare usually only slightly greater than the velocity <strong>of</strong> theair at the entrance to the compressor. As the pressureis built up by successive sets <strong>of</strong> rotors and stators, lessand less volume is required. Thus, the volume withinthe compressor is gradually decreased. At the exit <strong>of</strong>the compressor, a diffuser section adds the final stage tothe compression process by again decreasing velocity andincreasing static pressure just before the air enters theengine burner section.Normally, the temperature change caused by diffusionis not significant by itself. The temperature risewhich causes air to get hotter and hotter as it continuesthrough the compressor, is the result <strong>of</strong> the work beingdone on the air by the compressor rotors. Heating <strong>of</strong> theair occurs because <strong>of</strong> the compression process and becausesome <strong>of</strong> the mechanical energy <strong>of</strong> the rotor isconverted to heat energy.Because airflow in an axial compressor is generallydiffusing it is very unstable. High efficiency is maintainedonly at very small rates <strong>of</strong> diffusion. Compared to aturbine, quite a number <strong>of</strong> compressor stages are neededto keep the diffusion rate small through each individualstage. Also, the permissible turning angles <strong>of</strong> the bladesare considerably smaller than those which can be used inturbines. These are the reasons why an axial compressormust have many more stages than the turbine whichdrives it. In addition, more blades and consequentlymore stages are needed because the compressor, incontrast to a turbine, is endeavoring to push air in adirection that it does not want to go in.Dual CompressorThe dual compressor is a combination either <strong>of</strong> twoaxial compressors or <strong>of</strong> an axial and a centrifugal compressor(Figure 3-10). The dual-axial compressor consists <strong>of</strong>3-8