FM 1-506 Fundamentals of Aircraft Power Plants ... - Survival Books

FM 1-506 Fundamentals of Aircraft Power Plants ... - Survival Books

FM 1-506 Fundamentals of Aircraft Power Plants ... - Survival Books

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

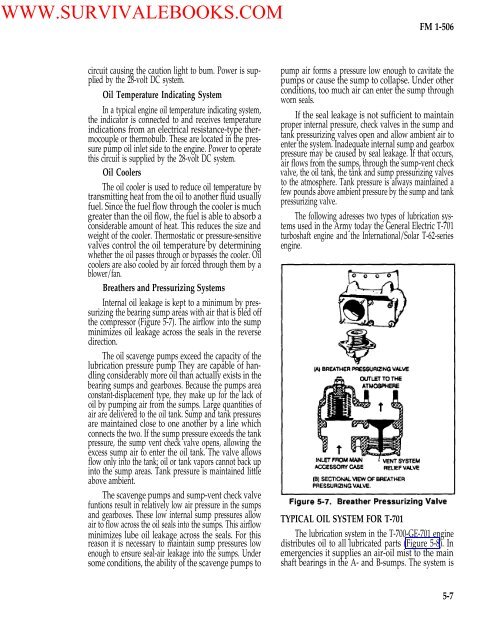

WWW.SURVIVALEBOOKS.COM<strong>FM</strong> 1-<strong>506</strong>circuit causing the caution light to bum. <strong>Power</strong> is suppliedby the 28-volt DC system.Oil Temperature Indicating SystemIn a typical engine oil temperature indicating system,the indicator is connected to and receives temperatureindications from an electrical resistance-type thermocoupleor thermobulb. These are located in the pressurepump oil inlet side to the engine. <strong>Power</strong> to operatethis circuit is supplied by the 28-volt DC system.Oil CoolersThe oil cooler is used to reduce oil temperature bytransmitting heat from the oil to another fluid usuallyfuel. Since the fuel flow through the cooler is muchgreater than the oil flow, the fuel is able to absorb aconsiderable amount <strong>of</strong> heat. This reduces the size andweight <strong>of</strong> the cooler. Thermostatic or pressure-sensitivevalves control the oil temperature by determiningwhether the oil passes through or bypasses the cooler. Oilcoolers are also cooled by air forced through them by ablower/fan.Breathers and Pressurizing SystemsInternal oil leakage is kept to a minimum by pressurizingthe bearing sump areas with air that is bled <strong>of</strong>fthe compressor (Figure 5-7). The airflow into the sumpminimizes oil leakage across the seals in the reversedirection.The oil scavenge pumps exceed the capacity <strong>of</strong> thelubrication pressure pump They are capable <strong>of</strong> handlingconsiderably more oil than actually exists in thebearing sumps and gearboxes. Because the pumps areaconstant-displacement type, they make up for the lack <strong>of</strong>oil by pumping air from the sumps. Large quantities <strong>of</strong>air are delivered to the oil tank. Sump and tank pressuresare maintained close to one another by a line whichconnects the two. If the sump pressure exceeds the tankpressure, the sump vent check valve opens, allowing theexcess sump air to enter the oil tank. The valve allowsflow only into the tank; oil or tank vapors cannot back upinto the sump areas. Tank pressure is maintained littleabove ambient.The scavenge pumps and sump-vent check valvefuntions result in relatively low air pressure in the sumpsand gearboxes. These low internal sump pressures allowair to flow across the oil seals into the sumps. This airflowminimizes lube oil leakage across the seals. For thisreason it is necessary to maintain sump pressures lowenough to ensure seal-air leakage into the sumps. Undersome conditions, the ability <strong>of</strong> the scavenge pumps topump air forms a pressure low enough to cavitate thepumps or cause the sump to collapse. Under otherconditions, too much air can enter the sump throughworn seals.If the seal leakage is not sufficient to maintainproper internal pressure, check valves in the sump andtank pressurizing valves open and allow ambient air toenter the system. Inadequate internal sump and gearboxpressure may be caused by seal leakage. If that occurs,air flows from the sumps, through the sump-vent checkvalve, the oil tank, the tank and sump pressurizing valvesto the atmosphere. Tank pressure is always maintained afew pounds above ambient pressure by the sump and tankpressurizing valve.The following adresses two types <strong>of</strong> lubrication systemsused in the Army today the General Electric T-701turboshaft engine and the International/Solar T-62-seriesengine.TYPICAL OIL SYSTEM FOR T-701The lubrication system in the T-700-GE-701 enginedistributes oil to all lubricated parts (Figure 5-8). Inemergencies it supplies an air-oil mist to the mainshaft bearings in the A- and B-sumps. The system is5-7