GENERAL CATALOG - K-Flex USA

GENERAL CATALOG - K-Flex USA

GENERAL CATALOG - K-Flex USA

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

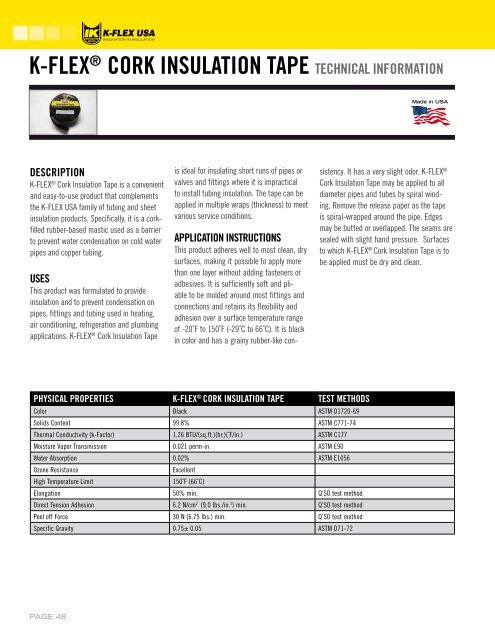

K-FLEX ® CORK INSULATION TAPE TECHNICAL INFORMATIONMade in <strong>USA</strong>DESCRIPTIONK-FLEX ® Cork Insulation Tape is a convenientand easy-to-use product that complementsthe K-FLEX <strong>USA</strong> family of tubing and sheetinsulation products. Specifically, it is a corkfilledrubber-based mastic used as a barrierto prevent water condensation on cold waterpipes and copper tubing.USESThis product was formulated to provideinsulation and to prevent condensation onpipes, fittings and tubing used in heating,air conditioning, refrigeration and plumbingapplications. K-FLEX ® Cork Insulation Tapeis ideal for insulating short runs of pipes orvalves and fittings where it is impracticalto install tubing insulation. The tape can beapplied in multiple wraps (thickness) to meetvarious service conditions.APPLICATION INSTRUCTIONSThis product adheres well to most clean, drysurfaces, making it possible to apply morethan one layer without adding fasteners oradhesives. It is sufficiently soft and pliableto be molded around most fittings andconnections and retains its flexibility andadhesion over a surface temperature rangeof -20˚F to 150˚F (-29˚C to 66˚C). It is blackin color and has a grainy rubber-like consistency.It has a very slight odor. K-FLEX ®Cork Insulation Tape may be applied to alldiameter pipes and tubes by spiral winding.Remove the release paper as the tapeis spiral-wrapped around the pipe. Edgesmay be butted or overlapped. The seams aresealed with slight hand pressure. Surfacesto which K-FLEX ® Cork Insulation Tape is tobe applied must be dry and clean.PHYSICAL PROPERTIES K-FLEX ® CORK INSULATION TAPE TEST METHODSColor Black ASTM D1720-69Solids Content 99.8% ASTM C771-74Thermal Conductivity (k-Factor) 1.26 BTU/(sq.ft.)(hr.)(˚F/in.) ASTM C177Moisture Vapor Transmission 0.021 perm-in ASTM E90Water Absorption 0.02% ASTM E1056Ozone ResistanceExcellentHigh Temperature Limit150˚F (66˚C)Elongation 50% min. Q’SO test methodDirect Tension Adhesion 6.2 N/cm 2 (9.0 lbs./in. 2 ) min. Q’SO test methodPeel off Force 30 N (6.75 lbs.) min. Q’SO test methodSpecific Gravity 0.75± 0.05 ASTM D71-72PAGE 48