Occupational Exposure to Carbon Nanotubes and Nanofibers

Occupational Exposure to Carbon Nanotubes and Nanofibers

Occupational Exposure to Carbon Nanotubes and Nanofibers

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

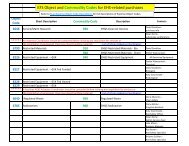

6.2 Engineering ControlsOne of the best ways <strong>to</strong> prevent adverse health effectsfrom exposure <strong>to</strong> CNT <strong>and</strong> CNF is <strong>to</strong> eliminateexposure <strong>and</strong> minimize risks early in the design orre-design of manufacturing <strong>and</strong> down-stream userprocesses (see NIOSH prevention through design(PtD) at: www.cdc.gov/niosh/<strong>to</strong>pics/PtD/). Thiscan be accomplished through the establishmen<strong>to</strong>f a process safety management (PSM) program.PSM entails the development <strong>and</strong> implementationof programs or systems <strong>to</strong> ensure that the practices<strong>and</strong> equipment used in potentially hazardous processesare adequate <strong>and</strong> appropriately maintained.An integral part of the PSM program is the conduc<strong>to</strong>f a process hazard analysis prior <strong>to</strong> the initiationof work <strong>to</strong> identify where sources of exposure <strong>to</strong>CNT or CNF may occur so that process equipmentcan be designed or re-designed <strong>to</strong> minimize therisk of exposure. At a minimum, the elements ofthe PSM program should be consistent with thoserequired in the OSHA Process Safety ManagementSt<strong>and</strong>ard [29 CFR 1910.119].In workplaces where CNT or CNF can’t be substitutedwith a less hazardous or nonhazardous materialthen all process equipment <strong>and</strong> other equipmentinvolved with the h<strong>and</strong>ling of CNT <strong>and</strong> CNFshould incorporate the necessary engineering controlmeasures <strong>to</strong> prevent worker exposure <strong>to</strong> CNT<strong>and</strong> CNF. Because of limited published workplaceexposure data for CNT <strong>and</strong> CNF, it is unknownwhether worker respirable mass exposures <strong>to</strong> CNT<strong>and</strong> CNF can be maintained at all workplaces belowthe NIOSH REL of 1 µg/m 3 EC as an 8-hourTWA. However, exposure control techniques suchas source enclosure (i.e., isolating the generationsource from the worker) <strong>and</strong> well-designed localexhaust ventilation (LEV) systems equipped withhigh efficiency particulate air (HEPA) filters havebeen shown <strong>to</strong> be effective for capturing airbornenanoparticles including CNT <strong>and</strong> CNF [Old <strong>and</strong>Methner 2008; NIOSH 2009a; Evans et al. 2010]. Ageneral description of exposure control techniques<strong>and</strong> their advantages <strong>and</strong> disadvantages is given inTable 6–6. The selection of the exposure controltechnique should take in<strong>to</strong> account the quantity<strong>and</strong> physical form of the nanomaterial (e.g., dispersiblepowder, liquid slurry, contained in a matrix)<strong>and</strong> the task duration <strong>and</strong> frequency in whichworkers come in<strong>to</strong> contact with the material (Table6–7). For instance, working with materials containingCNT or CNF (e.g., encapsulated in a solid) mayrequire a different type of an exposure control systemthan would be required for large quantities ofCNT <strong>and</strong> CNF in a highly dispersed free form. Processesinvolved in the cutting, grinding, or drillingof solid materials containing CNT or CNF shouldincorporate appropriate engineering controls (e.g.,local exhaust ventilation) <strong>to</strong> prevent aerosol release,whereas the manufacturing (i.e., product collectionat reac<strong>to</strong>r) <strong>and</strong> h<strong>and</strong>ling of dry bulk CNT orCNF should be performed in enclosed, <strong>and</strong> whenwarranted, HEPA-ventilated systems. HEPA filtrationhas been shown <strong>to</strong> be effective in capturingnanoscale particles <strong>and</strong> should be considered insituations where emissions may be regular, whereprocesses are repeated, <strong>and</strong> where higher quantitiesare used in a way that may lead <strong>to</strong> emissions. Theh<strong>and</strong>ling of research quantities of CNT <strong>and</strong> CNFin labora<strong>to</strong>ries is best performed using a labora<strong>to</strong>ryfume hood, such as a low-flow or air-curtain hood[Tsai et al. 2010], or use of a glove box <strong>to</strong> minimizeworker exposure [NIOSH 2012]. All exposure controlsystems should be properly designed, tested,<strong>and</strong> routinely maintained <strong>to</strong> ensure maximumefficiency [ACGIH 2007].6.3 Worker Education<strong>and</strong> TrainingEstablishing a program that includes the education<strong>and</strong> training of workers on the potential hazards ofCNT <strong>and</strong> CNF <strong>and</strong> their safe h<strong>and</strong>ling is critical<strong>to</strong> preventing adverse health effects from exposure.Research has shown that training can attain immediate<strong>and</strong> long-term objectives when (1) workersare educated about the potential hazards of theirjob, (2) there are improvements in knowledge <strong>and</strong>work practices, (3) workers are provided the necessaryskills <strong>to</strong> perform their job safely, <strong>and</strong> (4) there58 NIOSH CIB 65 • <strong>Carbon</strong> <strong>Nanotubes</strong> <strong>and</strong> <strong>Nanofibers</strong>