Occupational Exposure to Carbon Nanotubes and Nanofibers

Occupational Exposure to Carbon Nanotubes and Nanofibers

Occupational Exposure to Carbon Nanotubes and Nanofibers

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

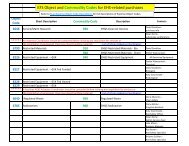

Table 6–7. Engineering controls <strong>to</strong> reduce CNT <strong>and</strong> CNF exposuresProcess/activityA. Pilot <strong>and</strong> research developmen<strong>to</strong>perationsPotential exposure source <strong>and</strong> recommendedcontainment of exposure*<strong>Exposure</strong> Source: Synthesis of CNT <strong>and</strong> CNF by fluidized-bed, chemicalvapor deposition, etc.: a) collection/harvesting after synthesis, b) powdertransfer, c) cleaning reac<strong>to</strong>r, d) removal of CNT <strong>and</strong> CNF from a substrate,e) purification <strong>and</strong>/or functionalization of CNT or CNF [note: potentialexposures are generally <strong>to</strong> small quantities of CNT <strong>and</strong> CNF (i.e., µg,mg) compared <strong>to</strong> exposure <strong>to</strong> larger amounts (e.g., kg) during full-scalemanufacturing/synthesis (see C below)].<strong>Exposure</strong> Controls: a) labora<strong>to</strong>ry fume hood (with HEPA filtered exhaustwhen warranted), b) HEPA-filtered exhausted enclosure (glove box), or c)biological safety cabinet. Local exhaust ventilation (LEV) may be requiredwhen opening reac<strong>to</strong>r <strong>and</strong> during harvesting.B. Research labora<strong>to</strong>ries <strong>Exposure</strong> Source: H<strong>and</strong>ling (e.g., mixing, weighing, blending, transferring)small quantities (e.g., µg, mg) of CNT or CNF powder or during sonicationof a CNT or CNF liquid suspension.<strong>Exposure</strong> Controls: a) labora<strong>to</strong>ry fume hood (with HEPA filtered exhaustwhen warranted), b) HEPA-filtered exhausted enclosure (glove boxisola<strong>to</strong>r), or c) biological safety cabinet.C. CNT <strong>and</strong> CNF manufacturing<strong>and</strong> synthesis<strong>Exposure</strong> Source: Synthesis of CNT <strong>and</strong> CNF by fluidized-bed, chemicalvapor deposition, etc., including: a) collection/harvesting after synthesis,b) drum <strong>and</strong> bag filling, c) powder transfer, d) cleaning reac<strong>to</strong>r, e) removalof CNT <strong>and</strong> CNF from a substrate, f) purification <strong>and</strong>/or functionalizationof CNT or CNF [Note: potential exposures are generally <strong>to</strong> large quantities(e.g., kg) of CNT <strong>and</strong> CNF].<strong>Exposure</strong> Controls: Dedicated ventilated room with HEPA filtered exhaust,<strong>and</strong>/or LEV at source of exposure with HEPA filtered exhaust. Examples:ventilated bagging/weighing station <strong>and</strong>/or laminar down-flow booth ornon-ventilation options such as continuous liner off-loading systems forbagging operations. Ventilated bag dumping stations for product transfer.See footnotes at end of table.(Continued)NIOSH CIB 65 • <strong>Carbon</strong> <strong>Nanotubes</strong> <strong>and</strong> <strong>Nanofibers</strong>61