EDC 2014 SR (UPDATED)

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>EDC</strong> <strong>2014</strong> Performance Report<br />

2<br />

RECORD-HIGH CASH FLOW TO DATE<br />

The second building block is our<br />

beginning cash balance of ₱16 billion,<br />

which was further strengthened by<br />

cash generated from operations<br />

amounting to ₱16.9 billion. More<br />

importantly, despite the impact of<br />

Typhoons Yolanda, Glenda, Seniang,<br />

and Ruby on our business, our EBITDA<br />

margin still stood at 58%. This cash<br />

flow is the lifeblood of the company,<br />

with which we will both sustain and<br />

grow the business.<br />

Our cash flows would have been<br />

stronger had it not been for the<br />

impact of the typhoons on our<br />

Bacman and Leyte business units,<br />

which combined made us lose a total<br />

of about ₱1.0 billion in cash revenues.<br />

In response to this clear, present, and<br />

worsening threat, we have brought<br />

serious engineering resources to<br />

bear. We have enhanced our systems<br />

for monitoring tropical depressions<br />

and storms. Most crucially, we are<br />

also improving the resiliency of<br />

our facilities through innovative<br />

engineering starting with the most<br />

vulnerable equipment: the cooling<br />

towers. We commissioned SPX Marley,<br />

maker of 68% of our cooling towers,<br />

to design solutions for our cooling<br />

towers so that these can withstand<br />

typhoon winds up to 300 kilometers<br />

per hour (kph). SPX Marley completed<br />

their designs in <strong>2014</strong> and these will be<br />

installed starting this July 2015.<br />

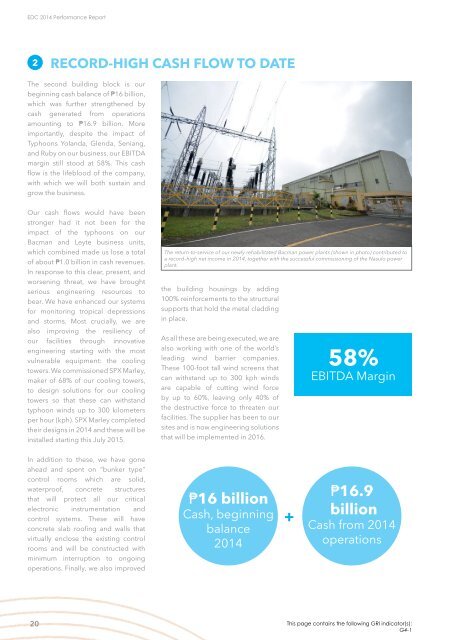

The return-to-service of our newly rehabilitated Bacman power plants (shown in photo) contributed to<br />

a record–high net income in <strong>2014</strong>, together with the successful commissioning of the Nasulo power<br />

plant.<br />

the building housings by adding<br />

100% reinforcements to the structural<br />

supports that hold the metal cladding<br />

in place.<br />

As all these are being executed, we are<br />

also working with one of the world’s<br />

leading wind barrier companies.<br />

These 100-foot tall wind screens that<br />

can withstand up to 300 kph winds<br />

are capable of cutting wind force<br />

by up to 60%, leaving only 40% of<br />

the destructive force to threaten our<br />

facilities. The supplier has been to our<br />

sites and is now engineering solutions<br />

that will be implemented in 2016.<br />

58%<br />

EBITDA Margin<br />

In addition to these, we have gone<br />

ahead and spent on “bunker type”<br />

control rooms which are solid,<br />

waterproof, concrete structures<br />

that will protect all our critical<br />

electronic instrumentation and<br />

control systems. These will have<br />

concrete slab roofing and walls that<br />

virtually enclose the existing control<br />

rooms and will be constructed with<br />

minimum interruption to ongoing<br />

operations. Finally, we also improved<br />

₱16 billion<br />

Cash, beginning<br />

balance<br />

<strong>2014</strong><br />

+<br />

₱16.9<br />

billion<br />

Cash from <strong>2014</strong><br />

operations<br />

20<br />

This page contains the following GRI indicator(s):<br />

G4-1