Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

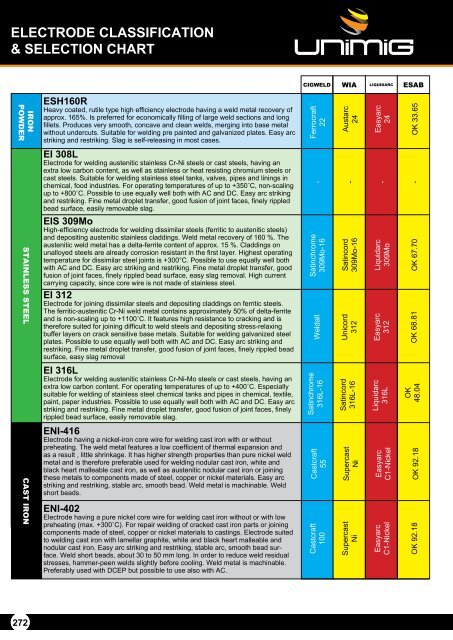

ELECTRODE CLASSIFICATION<br />

& SELECTION CHART<br />

CIGWELD WIA LIQUIDARC ESAB<br />

IRON<br />

POWDER<br />

ESH160R<br />

Heavy coated, rutile type high efficiency electrode having a weld metal recovery of<br />

approx. 165%. Is preferred for economically filling of large weld sections and long<br />

fillets. Produces very smooth, concave and clean welds, merging into base metal<br />

without undercuts. Suitable for welding pre painted and galvanized plates. Easy arc<br />

striking and <strong>res</strong>triking. Slag is self-releasing in most cases.<br />

Ferrocraft<br />

22<br />

Austarc<br />

24<br />

Easyarc<br />

24<br />

OK 33.65<br />

EI 308L<br />

Electrode for welding austenitic stainless Cr-Ni steels or cast steels, having an<br />

extra <strong>low</strong> carbon content, as well as stainless or heat <strong>res</strong>isting chromium steels or<br />

cast steels. Suitable for welding stainless steel tanks, valves, pipes and linings in<br />

chemical, food industries. For operating temperatu<strong>res</strong> of up to +350˚C, non-scaling<br />

up to +800˚C. Possible to use equally well both with AC and DC. Easy arc striking<br />

and <strong>res</strong>triking. Fine metal droplet transfer, good fusion of joint faces, finely rippled<br />

bead surface, easily removable slag.<br />

EIS 309Mo<br />

High-efficiency electrode for welding dissimilar steels (ferritic to austenitic steels)<br />

and depositing austenitic stainless claddings. Weld metal recovery of 160 %. The<br />

austenitic weld metal has a delta-ferrite content of approx. 15 %. Claddings on<br />

unalloyed steels are already corrosion <strong>res</strong>istant in the first layer. Highest operating<br />

temperature for dissimilar steel joints is +300°C. Possible to use equally well both<br />

with AC and DC. Easy arc striking and <strong>res</strong>triking. Fine metal droplet transfer, good<br />

fusion of joint faces, finely rippled bead surface, easy slag removal. High current<br />

carrying capacity, since core wire is not made of stainless steel.<br />

EI 312<br />

Electrode for joining dissimilar steels and depositing claddings on ferritic steels.<br />

The ferritic-austenitic Cr-Ni weld metal contains approximately 50% of delta-ferrite<br />

and is non-scaling up to +1100˚C. It featu<strong>res</strong> high <strong>res</strong>istance to cracking and is<br />

therefore suited for joining difficult to weld steels and depositing st<strong>res</strong>s-relaxing<br />

buffer layers on crack sensitive base metals. Suitable for welding galvanized steel<br />

plates. Possible to use equally well both with AC and DC. Easy arc striking and<br />

<strong>res</strong>triking. Fine metal droplet transfer, good fusion of joint faces, finely rippled bead<br />

surface, easy slag removal<br />

EI 316L<br />

Electrode for welding austenitic stainless Cr-Ni-Mo steels or cast steels, having an<br />

extra <strong>low</strong> carbon content. For operating temperatu<strong>res</strong> of up to +400˚C. Especially<br />

suitable for welding of stainless steel chemical tanks and pipes in chemical, textile,<br />

paint, paper industries. Possible to use equally well both with AC and DC. Easy arc<br />

striking and <strong>res</strong>triking. Fine metal droplet transfer, good fusion of joint faces, finely<br />

rippled bead surface, easily removable slag.<br />

-<br />

-<br />

-<br />

-<br />

STAINLESS STEEL<br />

Satinchrome<br />

309Mo-16<br />

Weldall<br />

Satincord <br />

309Mo-16<br />

Unicord<br />

312<br />

Liquidarc<br />

309Mo<br />

Easyarc<br />

312<br />

OK 67.70<br />

OK 68.81<br />

Satinchrome<br />

316L-16<br />

Satincord<br />

316L-16<br />

Liquidarc<br />

316L<br />

OK<br />

48.04<br />

CAST IRON<br />

ENI-416<br />

Electrode having a nickel-iron core wire for welding cast iron with or without <br />

preheating. The weld metal featu<strong>res</strong> a <strong>low</strong> coefficient of thermal expansion and<br />

as a <strong>res</strong>ult , little shrinkage. It has higher strength properties than pure nickel weld<br />

metal and is therefore preferable used for welding nodular cast iron, white and<br />

black heart malleable cast iron, as well as austenitic nodular cast iron or joining<br />

these metals to components made of steel, copper or nickel materials. Easy arc<br />

striking and <strong>res</strong>triking, stable arc, smooth bead. Weld metal is machinable. Weld<br />

short beads.<br />

ENI-402<br />

Electrode having a pure nickel core wire for welding cast iron without or with <strong>low</strong><br />

preheating (max. +300˚C). For repair welding of cracked cast iron parts or joining<br />

components made of steel, copper or nickel materials to castings. Electrode suited<br />

to welding cast iron with lamellar graphite, white and black heart malleable and<br />

nodular cast iron. Easy arc striking and <strong>res</strong>triking, stable arc, smooth bead surface.<br />

Weld short beads, about 30 to 50 mm long. In order to reduce weld <strong>res</strong>idual<br />

st<strong>res</strong>ses, hammer-peen welds slightly before cooling. Weld metal is machinable.<br />

Preferably used with DCEP but possible to use also with AC.<br />

Castcraft<br />

55<br />

Castcraft<br />

100<br />

Supercast<br />

Ni<br />

Supercast<br />

Ni<br />

Easyarc<br />

C1-Nickel<br />

Easyarc<br />

C1-Nickel<br />

OK 92.18<br />

OK 92.18<br />

272