- Page 1 and 2:

WELDING GUNS OF AUSTRALIA PTY LTD W

- Page 3 and 4:

ORDERS AND ENQUIRIES Welding Guns O

- Page 5 and 6:

MMA/TIG DC INVERTER WELDERS Page UN

- Page 7 and 8:

MIG - TIG - MMA DC INVERTER WELDERS

- Page 9 and 10:

INDUSTRIAL MIG TRANSFORMER WELDERS

- Page 11 and 12:

AC/DC TIG/MMA INVERTER WELDERS Page

- Page 13 and 14:

SPOT WELDING MACHINES Page TECNA 70

- Page 15 and 16:

UNIMIG VIPER ARC 140 MMA/TIG - 140

- Page 17 and 18:

UNIMIG VIPER ARC 160 MMA/TIG - 160

- Page 19 and 20:

RAZORWELD ARC 140 MMA/TIG - 140 Amp

- Page 21 and 22:

RAZORWELD ARC 180 MMA/TIG - 180 Amp

- Page 23 and 24:

RAZORWELD ARC 160 MMA/TIG - 160 Amp

- Page 25 and 26:

RAZORWELD ARC 200 MMA/TIG - 200 Amp

- Page 27 and 28:

ARC 400 TIG/MMA - 400 Amp DC Invert

- Page 29 and 30:

VIPER 200 DC TIG 200 Amp TIG/MMA We

- Page 31 and 32:

DIGITAL TIG 200 DC TIG/MMA - 200 Am

- Page 33 and 34:

VIPER 150 MIG/MMA 150 Amp MIG Welde

- Page 35 and 36:

VIPER 182 MIG/MMA 182 Amp MIG Welde

- Page 37 and 38:

RAZOR MIG 175 MIG/MMA - 175 Amp DC

- Page 39 and 40:

RAZOR MIG 200 MIG/MMA - 200 Amp DC

- Page 41 and 42:

RAZOR MIG 205 SMART SET MIG/TIG/MMA

- Page 43 and 44:

RAZOR 250 MTS MIG/TIG/MMA - 250 Amp

- Page 45 and 46:

RAZOR DIGITAL 250 MIG/TIG/MMA - 250

- Page 47 and 48:

RAZOR MIG 250 SWF MIG/TIG/MMA - 250

- Page 49 and 50:

RAZOR MIG 350 SWF MIG/TIG/MMA - 350

- Page 51 and 52:

RAZOR MIG 500 SWF Standard Torch Sp

- Page 53 and 54:

RAZORWELD 200 COMPACT MIG/TIG/MMA -

- Page 55 and 56:

RAZORWELD 250 COMPACT MIG/TIG/MMA -

- Page 57 and 58:

RAZORWELD 350 COMPACT MIG/TIG/MMA -

- Page 59 and 60:

WORKSHOP 270 Compact / 270SWF Torch

- Page 61 and 62:

WORKSHOP 345 Compact / 345SWF Torch

- Page 63 and 64:

WORKSHOP 390 Compact / 390SWF Torch

- Page 65 and 66:

WORKSHOP 425SWF / 500SWF Torch Spar

- Page 67 and 68:

DC PULSE MIG WELDER 206 Multi Funct

- Page 69 and 70:

MULTI 250KT - PLUS CONCEPT DC Multi

- Page 71 and 72:

MULTI 500SWF - Plus Concept DC Mult

- Page 73 and 74:

MULTI SYNERGIC 500SWF DC Multifunct

- Page 75 and 76:

RAZOR DIGITAL 200 AC/DC TIG/MMA - D

- Page 77 and 78:

UNIMIG TIG 200 AC/DC Square Wave, P

- Page 79 and 80:

UNIMIG TIG 315 AC/DC Square Wave, P

- Page 81 and 82:

AC/DC MULTIWAVE INVERTER WELDER DIG

- Page 83 and 84:

SITECUT 10 Plasma - 25Amp Inverter

- Page 85 and 86:

VIPERCUT 40 PLASMA Plasma - 40 Amp

- Page 87 and 88:

RAZOR CUT 45 Plasma - 45 Amp Invert

- Page 89 and 90:

RAZOR CUT 80 Plasma - 80 Amp Invert

- Page 91 and 92:

P-TRONIC 100 Plasma - 100 Amp Plasm

- Page 93 and 94:

MACHINE OPTIONS Accessories UMJRTRO

- Page 95 and 96:

ENGINE DRIVEN GENERATOR WELDER Raz

- Page 97 and 98:

RWS WIRE FEEDING UNIT Pulse MIG / D

- Page 99 and 100:

AUTOMATIC WELDERS HIT-8SS AUTOMATIC

- Page 101 and 102:

SPOT WELDERS Accessories for Models

- Page 103 and 104:

SUSPENDED GUNS Items 3321-3328 - 16

- Page 105 and 106:

Foot operated spot welders Items 46

- Page 107 and 108:

Pneumatic spot welders - Items 4645

- Page 109 and 110:

FUME EXTRACTION EQUIPMENT Mobile Si

- Page 111 and 112:

FUME EXTRACTION EQUIPMENT Mobile Do

- Page 113 and 114:

INDUSTRIAL GAS EQUIPMENT UNI-FLAME

- Page 115 and 116:

INDUSTRIAL GAS EQUIPMENT Pressure R

- Page 117 and 118:

INDUSTRIAL GAS EQUIPMENT Cutting Eq

- Page 119 and 120:

INDUSTRIAL GAS EQUIPMENT Flash Back

- Page 121 and 122:

INDUSTRIAL GAS EQUIPMENT CG30 Strai

- Page 123 and 124:

INDUSTRIAL GAS EQUIPMENT Straight L

- Page 125 and 126:

INDUSTRIAL GAS EQUIPMENT SG-30 Pipe

- Page 127 and 128:

PROTECTIVE SAFETY WEAR Welding Glov

- Page 129 and 130:

PROTECTIVE SAFETY WEAR Welding Jack

- Page 131 and 132:

PROTECTIVE SAFETY WEAR Welding Appa

- Page 133 and 134:

STARTER KITS UNIMIG Apprentice Bag

- Page 135 and 136:

PROTECTIVE SAFETY WEAR PAPR UNIT Po

- Page 137 and 138:

PROTECTIVE SAFETY WEAR Automatic We

- Page 139 and 140:

PROTECTIVE SAFETY WEAR Automatic We

- Page 141 and 142:

PROTECTIVE SAFETY WEAR Automatic We

- Page 143 and 144:

ARC ACCESSORIES Electrode Holders,

- Page 145 and 146:

ARC ACCESSORIES Cable Lugs, Chippin

- Page 147 and 148:

ARC ACCESSORIES Chalk, Testing Spra

- Page 149 and 150:

3 Years Warranty MIG ACCESSORIES Al

- Page 151 and 152:

MIG WELDING TORCHES Suregrip Series

- Page 153 and 154:

Suregrip Series SB15 MIG TORCH Fron

- Page 155 and 156:

Suregrip Series SB24 MIG TORCH Fron

- Page 157 and 158:

Suregrip Series SB25 MIG TORCH Fron

- Page 159 and 160:

Suregrip Series SB36 MIG TORCH Fron

- Page 161 and 162:

Suregrip Series SB38 MIG TORCH Fron

- Page 163 and 164:

Suregrip Series SB500 MIG TORCH Fro

- Page 165 and 166:

MIG WELDING TORCHES Suregrip Series

- Page 167 and 168:

Suregrip Series 360AMP PUSH PULL MI

- Page 169 and 170:

Suregrip Series 400AMP PUSH PULL WC

- Page 171 and 172:

AUTOGEN RITTER PPL 260/360 MIG TORC

- Page 173 and 174:

DIGITAL MIG WELDING TORCHES Suregri

- Page 175 and 176:

Suregrip Series DM24 DIGITAL MIG TO

- Page 177 and 178:

Suregrip Series DM26 DIGITAL MIG TO

- Page 179 and 180:

Suregrip Series DM36 DIGITAL MIG TO

- Page 181 and 182:

SPG135 AMP SPOOL GUN Duty Cycle 30%

- Page 183 and 184:

SPG200II AMP SPOOL GUN Front end co

- Page 185 and 186:

Suregrip Series 240AMP SPOOL GUN Fr

- Page 187 and 188:

MIG WELDING TORCHES Suregrip TWC Se

- Page 189 and 190:

Suregrip Series BND 300 MIG TORCH F

- Page 191 and 192:

Suregrip Series BND 400 MIG TORCH F

- Page 193 and 194:

Suregrip Series TWC2 STYLE MIG TORC

- Page 195 and 196:

Suregrip Series TWC4 STYLE MIG TORC

- Page 197 and 198:

Suregrip Series TWC5 STYLE MIG TORC

- Page 199 and 200:

TIG WELDING TORCHES Suregrip Series

- Page 201 and 202:

Suregrip Series 9V ERGO TIG TORCH S

- Page 203 and 204:

Suregrip Series 17V TIG TORCH Stand

- Page 205 and 206:

Suregrip Series 26V TIG TORCH Stand

- Page 207 and 208:

TIG WELDING TORCHES Suregrip Series

- Page 209 and 210:

Suregrip Series SR9 ERGO TIG TORCH

- Page 211 and 212:

Suregrip Series SR17 ERGO TIG TORCH

- Page 213 and 214:

Suregrip Series SR26 ERGO TIG TORCH

- Page 215 and 216:

Suregrip Series SR18 ERGO TIG TORCH

- Page 217 and 218:

WELDING CONSUMABLE RED NECK TIG KIT

- Page 219 and 220:

PLASMA CUTTING TORCHES PT25C S25 Pl

- Page 221 and 222:

PLASMA CUTTING TORCHES TD35 SC80 Pl

- Page 223 and 224:

PLASMA CUTTING TORCHES TD35 CBR150

- Page 225 and 226:

PLASMA CUTTING TORCHES TD35 S45 Pla

- Page 227 and 228:

PLASMA CUTTING TORCHES PTM-100 Plas

- Page 229 and 230:

7 7a 7b 7c 7d 5 5a 5b1 5c1a5d1b5e1c

- Page 231 and 232:

11 12 PLASMA CUTTING 13a 13a 13a TO

- Page 233 and 234:

PLASMA CUTTING TORCHES TD35 T100 Pl

- Page 235 and 236:

PLASMA CUTTING TORCHES TD35 T150 Pl

- Page 237 and 238:

12 11 PLASMA CUTTING TORCHES TD35 P

- Page 239 and 240:

PLASMA CUTTING TORCHES TD35 PCH/M25

- Page 241 and 242:

PLASMA CUTTING TORCHES TD35 PCH/M35

- Page 243 and 244:

PLASMA CUTTING TORCHES TD35 PCH/M52

- Page 245 and 246:

PLASMA CUTTING TORCHES TD35 PCH/M15

- Page 247 and 248:

PLASMA CUTTING TORCHES PCH 75 / 100

- Page 249 and 250: PLASMA CUTTING TORCHES TD35 MAX Pla

- Page 251 and 252: PLASMA CUTTING TORCHES TD35 MAX Pla

- Page 253 and 254: PLASMA CUTTING TORCHES MAX 200 Plas

- Page 255 and 256: PLASMA CUTTING TORCHES ICE 25 Plasm

- Page 257 and 258: PLASMA CUTTING TORCHES TD35 ICE 70/

- Page 259 and 260: WELDING EQUIPMENT & CONSUMABLE Prod

- Page 261 and 262: WIRE FEED DRIVE ROLLERS To Suit UNI

- Page 263 and 264: WELDING CONSUMABLES ER70S-6 Solid M

- Page 265 and 266: WELDING CONSUMABLE Aluminium MIG Wi

- Page 267 and 268: WELDING CONSUMABLE Silicon Bronze M

- Page 269 and 270: WELDING CONSUMABLE Aluminium TIG Ro

- Page 271 and 272: ELECTRODE CLASSIFICATION & SELECTIO

- Page 273 and 274: WELDING CONSUMABLE General Purpose

- Page 275 and 276: WELDING CONSUMABLE Low Hydrogen Ele

- Page 277 and 278: WELDING CONSUMABLE Hard Facing Elec

- Page 279 and 280: WELDING CONSUMABLE Stainless Steel

- Page 281 and 282: WELDING CONSUMABLE Cast Iron ENI 40

- Page 283 and 284: TECHNICAL NOTES MMA MMA (Manual Met

- Page 285 and 286: TECHNICAL NOTES MIG MIG (Metal Iner

- Page 287 and 288: TECHNICAL NOTES MIG Basic MIG Weldi

- Page 289 and 290: TECHNICAL NOTES MIG Travel Speed -

- Page 291 and 292: TECHNICAL NOTES MIG Wire Feed Rolle

- Page 293 and 294: TECHNICAL NOTES TIG DC Pulse TIG We

- Page 295 and 296: TECHNICAL NOTES TIG TIG Welding Fus

- Page 297 and 298: TECHNICAL NOTES TIG In older machin

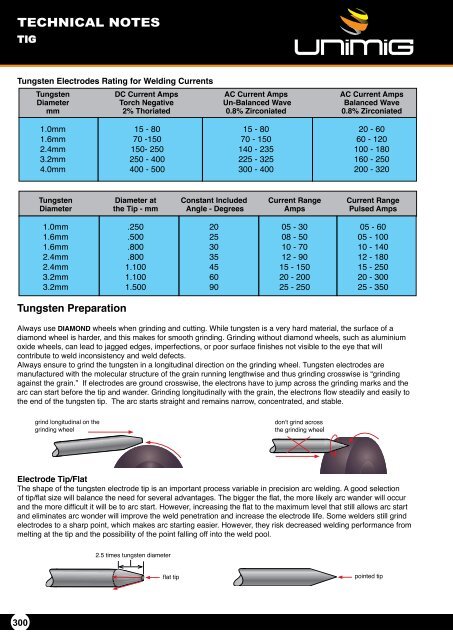

- Page 299: TECHNICAL NOTES TIG Tungsten Electr

- Page 303 and 304: TECHNICAL NOTES Operating Procedure

- Page 305 and 306: TECHNICAL NOTES PLASMA Hold the tor

- Page 307 and 308: Welding Guns of Australia Pty Ltd -