Inorganic Microporous Membranes for Gas Separation in Fossil Fuel ...

Inorganic Microporous Membranes for Gas Separation in Fossil Fuel ...

Inorganic Microporous Membranes for Gas Separation in Fossil Fuel ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

4 Results and discussion<br />

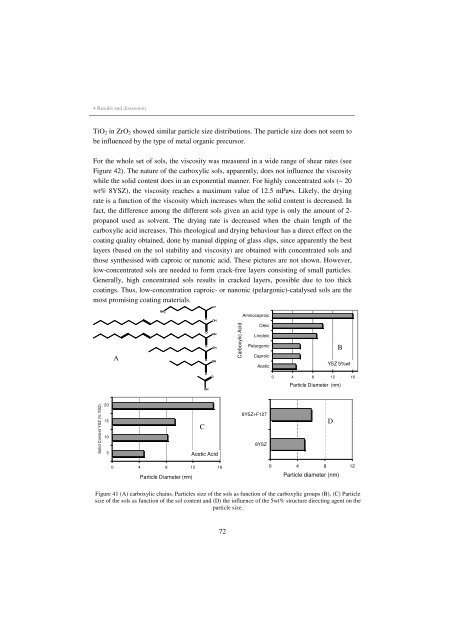

TiO2 <strong>in</strong> ZrO2 showed similar particle size distributions. The particle size does not seem to<br />

be <strong>in</strong>fluenced by the type of metal organic precursor.<br />

For the whole set of sols, the viscosity was measured <strong>in</strong> a wide range of shear rates (see<br />

Figure 42). The nature of the carboxylic sols, apparently, does not <strong>in</strong>fluence the viscosity<br />

while the solid content does <strong>in</strong> an exponential manner. For highly concentrated sols (~ 20<br />

wt% 8YSZ), the viscosity reaches a maximum value of 12.5 mPa•s. Likely, the dry<strong>in</strong>g<br />

rate is a function of the viscosity which <strong>in</strong>creases when the solid content is decreased. In<br />

fact, the difference among the different sols given an acid type is only the amount of 2propanol<br />

used as solvent. The dry<strong>in</strong>g rate is decreased when the cha<strong>in</strong> length of the<br />

carboxylic acid <strong>in</strong>creases. This rheological and dry<strong>in</strong>g behaviour has a direct effect on the<br />

coat<strong>in</strong>g quality obta<strong>in</strong>ed, done by manual dipp<strong>in</strong>g of glass slips, s<strong>in</strong>ce apparently the best<br />

layers (based on the sol stability and viscosity) are obta<strong>in</strong>ed with concentrated sols and<br />

those synthesised with caproic or nanonic acid. These pictures are not shown. However,<br />

low-concentrated sols are needed to <strong>for</strong>m crack-free layers consist<strong>in</strong>g of small particles.<br />

Generally, high concentrated sols results <strong>in</strong> cracked layers, possible due to too thick<br />

coat<strong>in</strong>gs. Thus, low-concentration caproic- or nanonic (pelargonic)-catalysed sols are the<br />

most promis<strong>in</strong>g coat<strong>in</strong>g materials.<br />

Solid Content YSZ (% YSZ)<br />

20<br />

15<br />

10<br />

5<br />

A<br />

NH 2<br />

O<br />

OH<br />

OH<br />

O<br />

OH<br />

O<br />

OH<br />

O<br />

OH<br />

O<br />

O<br />

OH<br />

0 4 8 12 16<br />

Particle Diameter (nm)<br />

C<br />

Acetic Acid<br />

72<br />

Carboxylic Acid<br />

Am<strong>in</strong>ocaproic<br />

Oleic<br />

L<strong>in</strong>oleic<br />

Pelargonic<br />

Caproic<br />

Acetic<br />

8YSZ+F127<br />

8YSZ<br />

YSZ 5%wt<br />

0 4 8 12 16<br />

Particle Diameter (nm)<br />

0 4 8 12<br />

Particle diameter (nm)<br />

Figure 41 (A) carboxylic cha<strong>in</strong>s. Particles size of the sols as function of the carboxylic groups (B), (C) Particle<br />

size of the sols as function of the sol content and (D) the <strong>in</strong>fluence of the 5wt% structure direct<strong>in</strong>g agent on the<br />

particle size.<br />

D<br />

B