special - Alu-web.de

special - Alu-web.de

special - Alu-web.de

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

SPECIAL<br />

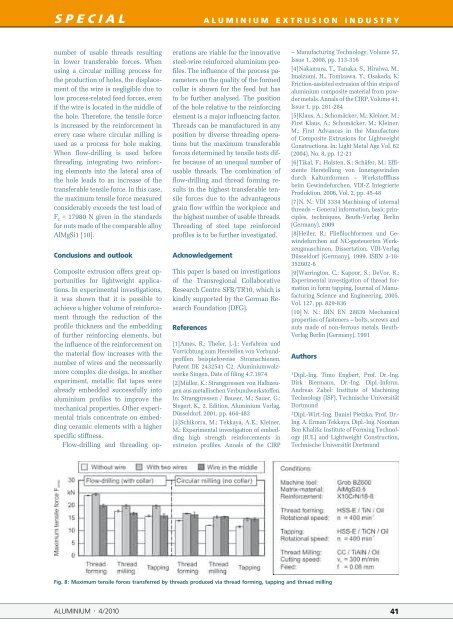

number of usable threads resulting<br />

in lower transferable forces. When<br />

using a circular milling process for<br />

the production of holes, the displacement<br />

of the wire is negligible due to<br />

low process-related feed forces, even<br />

if the wire is located in the middle of<br />

the hole. Therefore, the tensile force<br />

is increased by the reinforcement in<br />

every case where circular milling is<br />

used as a process for hole making.<br />

When flow-drilling is used before<br />

threading, integrating two reinforcing<br />

elements into the lateral area of<br />

the hole leads to an increase of the<br />

transferable tensile force. In this case,<br />

the maximum tensile force measured<br />

consi<strong>de</strong>rably exceeds the test load of<br />

F z = 17980 N given in the standards<br />

for nuts ma<strong>de</strong> of the comparable alloy<br />

AlMgSi1 [10].<br />

Conclusions and outlook<br />

Composite extrusion offers great opportunities<br />

for lightweight applications.<br />

In experimental investigations,<br />

it was shown that it is possible to<br />

achieve a higher volume of reinforcement<br />

through the reduction of the<br />

profile thickness and the embedding<br />

of further reinforcing elements, but<br />

the influence of the reinforcement on<br />

the material flow increases with the<br />

number of wires and the necessarily<br />

more complex die <strong>de</strong>sign. In another<br />

experiment, metallic flat tapes were<br />

already embed<strong>de</strong>d successfully into<br />

aluminium profiles to improve the<br />

mechanical properties. Other experimental<br />

trials concentrate on embedding<br />

ceramic elements with a higher<br />

specific stiffness.<br />

Flow-drilling and threading op-<br />

ALUMINIUM · 4/2010<br />

ALUMINIUM EXTRUSION INDUSTRY<br />

erations are viable for the innovative<br />

steel-wire reinforced aluminium profiles.<br />

The influence of the process parameters<br />

on the quality of the formed<br />

collar is shown for the feed but has<br />

to be further analysed. The position<br />

of the hole relative to the reinforcing<br />

element is a major influencing factor.<br />

Threads can be manufactured in any<br />

position by diverse threading operations<br />

but the maximum transferable<br />

forces <strong>de</strong>termined by tensile tests differ<br />

because of an unequal number of<br />

usable threads. The combination of<br />

flow-drilling and thread forming results<br />

in the highest transferable tensile<br />

forces due to the advantageous<br />

grain flow within the workpiece and<br />

the highest number of usable threads.<br />

Threading of steel tape reinforced<br />

profiles is to be further investigated.<br />

Acknowledgement<br />

This paper is based on investigations<br />

of the Transregional Collaborative<br />

Research Centre SFB/TR10, which is<br />

kindly supported by the German Research<br />

Foundation (DFG).<br />

References<br />

[1] Ames, R.; Theler, J.-J.: Verfahren und<br />

Vorrichtung zum Herstellen von Verbundprofilen<br />

beispielsweise Stromschienen.<br />

Patent DE 2432541 C2, <strong>Alu</strong>miniumwalzwerke<br />

Singen, Date of filing 4.7.1974<br />

[2] Müller, K.: Strangpressen von Halbzeugen<br />

aus metallischen Verbundwerkstoffen.<br />

In: Strangpressen / Bauser, M.; Sauer, G.;<br />

Siegert, K., 2. Edition, <strong>Alu</strong>minium Verlag,<br />

Düsseldorf, 2001, pp. 464-483<br />

[3] Schikorra, M.; Tekkaya, A. E.; Kleiner,<br />

M.: Experimental investigation of embedding<br />

high strength reinforcements in<br />

extrusion profiles. Annals of the CIRP<br />

Fig. 8: Maximum tensile forces transferred by threads produced via thread forming, tapping and thread milling<br />

– Manufacturing Technology, Volume 57,<br />

Issue 1, 2008, pp. 313-316<br />

[4] Nakamura, T., Tanaka, S., Hiraiwa, M.,<br />

Imaizumi, H., Tomizawa, Y., Osakada, K:<br />

Friction-assisted extrusion of thin strips of<br />

aluminium composite material from pow<strong>de</strong>r<br />

metals. Annals of the CIRP, Volume 41,<br />

Issue 1, pp. 281-284<br />

[5] Klaus, A.; Schomäcker, M.; Kleiner, M.:<br />

First Klaus, A.; Schomäcker, M.; Kleiner,<br />

M.: First Advances in the Manufacture<br />

of Composite Extrusions for Lightweight<br />

Constructions. In: Light Metal Age Vol. 62<br />

(2004), No. 8, pp. 12-21<br />

[6] Tikal, F.; Holsten, S.; Schäfer, M.: Effiziente<br />

Herstellung von Innengewin<strong>de</strong>n<br />

durch Kaltumformen – Werkstofffluss<br />

beim Gewin<strong>de</strong>furchen, VDI-Z Integrierte<br />

Produktion, 2006, Vol. 2, pp. 45-48<br />

[7] N. N.: VDI 3334 Machining of internal<br />

threads – General information, basic principles,<br />

techniques, Beuth-Verlag Berlin<br />

(Germany), 2009<br />

[8] Heiler, R.: Fließlochformen und Gewin<strong>de</strong>furchen<br />

auf NC-gesteuerten Werkzeugmaschinen,<br />

Dissertation, VDI-Verlag<br />

Düsseldorf (Germany), 1999, ISBN 3-18-<br />

352602-6<br />

[9] Warrington, C.; Kapoor, S.; DeVor, R.:<br />

Experimental investigation of thread formation<br />

in form tapping, Journal of Manufacturing<br />

Science and Engineering, 2005,<br />

Vol. 127, pp. 829-836<br />

[10] N. N.: DIN EN 28839 Mechanical<br />

properties of fasteners – bolts, screws and<br />

nuts ma<strong>de</strong> of non-ferrous metals, Beuth-<br />

Verlag Berlin (Germany), 1991<br />

Authors<br />

1 Dipl.-Ing. Timo Engbert, Prof. Dr.-Ing.<br />

Dirk Biermann, Dr.-Ing. Dipl.-Inform.<br />

Andreas Zabel: Institute of Machining<br />

Technology (ISF), Technische Universität<br />

Dortmund<br />

2 Dipl.-Wirt.-Ing. Daniel Pietzka, Prof. Dr.-<br />

Ing. A. Erman Tekkaya, Dipl.-Ing. Nooman<br />

Ben Khalifa: Institute of Forming Technology<br />

(IUL) and Lightweight Construction,<br />

Technische Universität Dortmund<br />

41