© 2006 by Taylor & Francis Group, LLC

© 2006 by Taylor & Francis Group, LLC

© 2006 by Taylor & Francis Group, LLC

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Abrasive Blasting and Heavy-Metal Contamination 87<br />

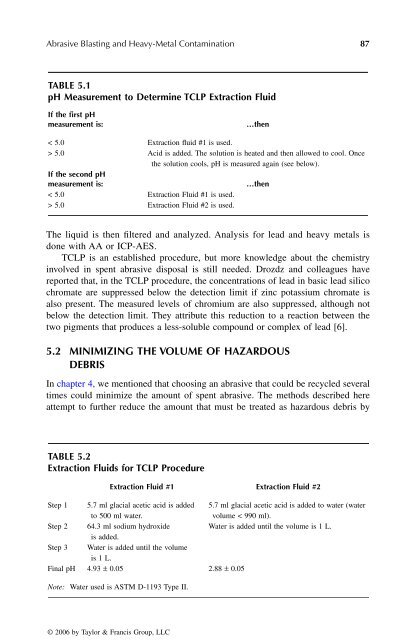

TABLE 5.1<br />

pH Measurement to Determine TCLP Extraction Fluid<br />

If the first pH<br />

measurement is: …then<br />

< 5.0 Extraction fluid #1 is used.<br />

> 5.0 Acid is added. The solution is heated and then allowed to cool. Once<br />

the solution cools, pH is measured again (see below).<br />

If the second pH<br />

measurement is: …then<br />

< 5.0 Extraction Fluid #1 is used.<br />

> 5.0 Extraction Fluid #2 is used.<br />

The liquid is then filtered and analyzed. Analysis for lead and heavy metals is<br />

done with AA or ICP-AES.<br />

TCLP is an established procedure, but more knowledge about the chemistry<br />

involved in spent abrasive disposal is still needed. Drozdz and colleagues have<br />

reported that, in the TCLP procedure, the concentrations of lead in basic lead silico<br />

chromate are suppressed below the detection limit if zinc potassium chromate is<br />

also present. The measured levels of chromium are also suppressed, although not<br />

below the detection limit. They attribute this reduction to a reaction between the<br />

two pigments that produces a less-soluble compound or complex of lead [6].<br />

5.2 MINIMIZING THE VOLUME OF HAZARDOUS<br />

DEBRIS<br />

In chapter 4, we mentioned that choosing an abrasive that could be recycled several<br />

times could minimize the amount of spent abrasive. The methods described here<br />

attempt to further reduce the amount that must be treated as hazardous debris <strong>by</strong><br />

TABLE 5.2<br />

Extraction Fluids for TCLP Procedure<br />

Extraction Fluid #1 Extraction Fluid #2<br />

Step 1 5.7 ml glacial acetic acid is added 5.7 ml glacial acetic acid is added to water (water<br />

to 500 ml water.<br />

volume < 990 ml).<br />

Step 2 64.3 ml sodium hydroxide<br />

is added.<br />

Water is added until the volume is 1 L.<br />

Step 3 Water is added until the volume<br />

is 1 L.<br />

Final pH 4.93 ± 0.05 2.88 ± 0.05<br />

Note: Water used is ASTM D-1193 Type II.<br />

<strong>©</strong> <strong>2006</strong> <strong>by</strong> <strong>Taylor</strong> & <strong>Francis</strong> <strong>Group</strong>, <strong>LLC</strong>