© 2006 by Taylor & Francis Group, LLC

© 2006 by Taylor & Francis Group, LLC

© 2006 by Taylor & Francis Group, LLC

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Corrosion Testing — Background and Theoretical Considerations 119<br />

ln (D)<br />

2<br />

1<br />

0<br />

0 20 40 60 80 100<br />

−1<br />

−2<br />

Rdry<br />

CRS, 0 Zn<br />

EGS, 20 Zn<br />

EGS, 40 Zn<br />

HDG, 90 Zn<br />

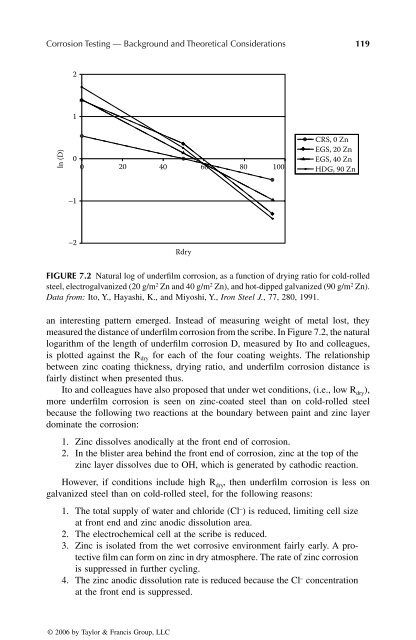

FIGURE 7.2 Natural log of underfilm corrosion, as a function of drying ratio for cold-rolled<br />

steel, electrogalvanized (20 g/m 2 Zn and 40 g/m 2 Zn), and hot-dipped galvanized (90 g/m 2 Zn).<br />

Data from: Ito, Y., Hayashi, K., and Miyoshi, Y., Iron Steel J., 77, 280, 1991.<br />

an interesting pattern emerged. Instead of measuring weight of metal lost, they<br />

measured the distance of underfilm corrosion from the scribe. In Figure 7.2, the natural<br />

logarithm of the length of underfilm corrosion D, measured <strong>by</strong> Ito and colleagues,<br />

is plotted against the R dry for each of the four coating weights. The relationship<br />

between zinc coating thickness, drying ratio, and underfilm corrosion distance is<br />

fairly distinct when presented thus.<br />

Ito and colleagues have also proposed that under wet conditions, (i.e., low R dry),<br />

more underfilm corrosion is seen on zinc-coated steel than on cold-rolled steel<br />

because the following two reactions at the boundary between paint and zinc layer<br />

dominate the corrosion:<br />

1. Zinc dissolves anodically at the front end of corrosion.<br />

2. In the blister area behind the front end of corrosion, zinc at the top of the<br />

zinc layer dissolves due to OH, which is generated <strong>by</strong> cathodic reaction.<br />

However, if conditions include high R dry, then underfilm corrosion is less on<br />

galvanized steel than on cold-rolled steel, for the following reasons:<br />

1. The total supply of water and chloride (Cl – ) is reduced, limiting cell size<br />

at front end and zinc anodic dissolution area.<br />

2. The electrochemical cell at the scribe is reduced.<br />

3. Zinc is isolated from the wet corrosive environment fairly early. A protective<br />

film can form on zinc in dry atmosphere. The rate of zinc corrosion<br />

is suppressed in further cycling.<br />

4. The zinc anodic dissolution rate is reduced because the Cl – concentration<br />

at the front end is suppressed.<br />

<strong>©</strong> <strong>2006</strong> <strong>by</strong> <strong>Taylor</strong> & <strong>Francis</strong> <strong>Group</strong>, <strong>LLC</strong>