© 2006 by Taylor & Francis Group, LLC

© 2006 by Taylor & Francis Group, LLC

© 2006 by Taylor & Francis Group, LLC

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Abrasive Blasting and Heavy-Metal Contamination 91<br />

While it is arguable that iron could form temporary, weak, ionic complexes…so that<br />

when analyzed <strong>by</strong> the TCLP test the lead appears to have been stabilized, the Agency<br />

believes that this ‘‘stabilization” is temporary, based upon the nature of the complexing.<br />

In fact, a report prepared <strong>by</strong> the EPA on Iron Chemistry in Lead-Contaminated Materials<br />

(Feb. 22 1994), which specifically addressed this issue, found that iron-lead bonds are<br />

weak, adsorptive surface bonds, and therefore not likely to be permanent. Furthermore,<br />

as this iron-rich mixture is exposed to moisture and oxidative conditions over time,<br />

interstitial water would likely acidify, which could potentially reverse any temporary<br />

stabilization, as well as increase the leachability of the lead…. Therefore, the addition<br />

of iron dust or filings to…waste…does not appear to provide long-term treatment.<br />

5.3.2 STABILIZATION OF LEAD THROUGH PH ADJUSTMENT<br />

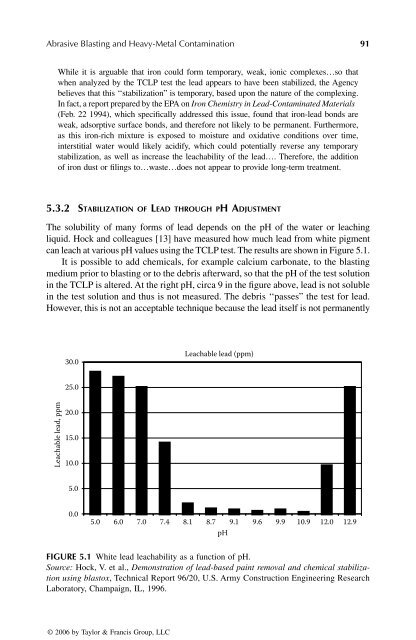

The solubility of many forms of lead depends on the pH of the water or leaching<br />

liquid. Hock and colleagues [13] have measured how much lead from white pigment<br />

can leach at various pH values using the TCLP test. The results are shown in Figure 5.1.<br />

It is possible to add chemicals, for example calcium carbonate, to the blasting<br />

medium prior to blasting or to the debris afterward, so that the pH of the test solution<br />

in the TCLP is altered. At the right pH, circa 9 in the figure above, lead is not soluble<br />

in the test solution and thus is not measured. The debris ‘‘passes” the test for lead.<br />

However, this is not an acceptable technique because the lead itself is not permanently<br />

Leachable lead, ppm<br />

30.0<br />

25.0<br />

20.0<br />

15.0<br />

10.0<br />

5.0<br />

0.0<br />

Leachable lead (ppm)<br />

5.0 6.0 7.0 7.4 8.1 8.7 9.1 9.6 9.9 10.9 12.0 12.9<br />

pH<br />

FIGURE 5.1 White lead leachability as a function of pH.<br />

Source: Hock, V. et al., Demonstration of lead-based paint removal and chemical stabilization<br />

using blastox, Technical Report 96/20, U.S. Army Construction Engineering Research<br />

Laboratory, Champaign, IL, 1996.<br />

<strong>©</strong> <strong>2006</strong> <strong>by</strong> <strong>Taylor</strong> & <strong>Francis</strong> <strong>Group</strong>, <strong>LLC</strong>