BIR-Herbsttagung, 25. - 26- Oktober 2010 in Brüssel - Metall-web.de

BIR-Herbsttagung, 25. - 26- Oktober 2010 in Brüssel - Metall-web.de

BIR-Herbsttagung, 25. - 26- Oktober 2010 in Brüssel - Metall-web.de

Sie wollen auch ein ePaper? Erhöhen Sie die Reichweite Ihrer Titel.

YUMPU macht aus Druck-PDFs automatisch weboptimierte ePaper, die Google liebt.

METALL-FORSCHUNG<br />

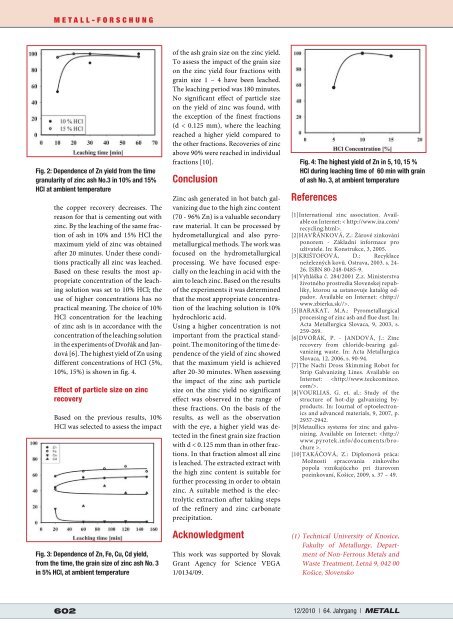

Fig. 2: Depen<strong>de</strong>nce of Zn yield from the time<br />

granularity of z<strong>in</strong>c ash No.3 <strong>in</strong> 10% and 15%<br />

HCl at ambient temperature<br />

the copper recovery <strong>de</strong>creases. The<br />

reason for that is cement<strong>in</strong>g out with<br />

z<strong>in</strong>c. By the leach<strong>in</strong>g of the same fraction<br />

of ash <strong>in</strong> 10% and 15% HCl the<br />

maximum yield of z<strong>in</strong>c was obta<strong>in</strong>ed<br />

after 20 m<strong>in</strong>utes. Un<strong>de</strong>r these conditions<br />

practically all z<strong>in</strong>c was leached.<br />

Based on these results the most appropriate<br />

concentration of the leach<strong>in</strong>g<br />

solution was set to 10% HCl; the<br />

use of higher concentrations has no<br />

practical mean<strong>in</strong>g. The choice of 10%<br />

HCl concentration for the leach<strong>in</strong>g<br />

of z<strong>in</strong>c ash is <strong>in</strong> accordance with the<br />

concentration of the leach<strong>in</strong>g solution<br />

<strong>in</strong> the experiments of Dvořák and Jandová<br />

[6]. The highest yield of Zn us<strong>in</strong>g<br />

different concentrations of HCl (5%,<br />

10%, 15%) is shown <strong>in</strong> fig. 4.<br />

Effect of particle size on z<strong>in</strong>c<br />

recovery<br />

Based on the previous results, 10%<br />

HCl was selected to assess the impact<br />

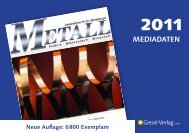

Fig. 3: Depen<strong>de</strong>nce of Zn, Fe, Cu, Cd yield,<br />

from the time, the gra<strong>in</strong> size of z<strong>in</strong>c ash No. 3<br />

<strong>in</strong> 5% HCl, at ambient temperature<br />

602<br />

of the ash gra<strong>in</strong> size on the z<strong>in</strong>c yield.<br />

To assess the impact of the gra<strong>in</strong> size<br />

on the z<strong>in</strong>c yield four fractions with<br />

gra<strong>in</strong> size 1 – 4 have been leached.<br />

The leach<strong>in</strong>g period was 180 m<strong>in</strong>utes.<br />

No significant effect of particle size<br />

on the yield of z<strong>in</strong>c was found, with<br />

the exception of the f<strong>in</strong>est fractions<br />

(d < 0.125 mm), where the leach<strong>in</strong>g<br />

reached a higher yield compared to<br />

the other fractions. Recoveries of z<strong>in</strong>c<br />

above 90% were reached <strong>in</strong> <strong>in</strong>dividual<br />

fractions [10].<br />

Conclusion<br />

Z<strong>in</strong>c ash generated <strong>in</strong> hot batch galvaniz<strong>in</strong>g<br />

due to the high z<strong>in</strong>c content<br />

(70 - 96% Zn) is a valuable secondary<br />

raw material. It can be processed by<br />

hydrometallurgical and also pyrometallurgical<br />

methods. The work was<br />

focused on the hydrometallurgical<br />

process<strong>in</strong>g. We have focused especially<br />

on the leach<strong>in</strong>g <strong>in</strong> acid with the<br />

aim to leach z<strong>in</strong>c. Based on the results<br />

of the experiments it was <strong>de</strong>term<strong>in</strong>ed<br />

that the most appropriate concentration<br />

of the leach<strong>in</strong>g solution is 10%<br />

hydrochloric acid.<br />

Us<strong>in</strong>g a higher concentration is not<br />

important from the practical standpo<strong>in</strong>t.<br />

The monitor<strong>in</strong>g of the time <strong>de</strong>pen<strong>de</strong>nce<br />

of the yield of z<strong>in</strong>c showed<br />

that the maximum yield is achieved<br />

after 20-30 m<strong>in</strong>utes. When assess<strong>in</strong>g<br />

the impact of the z<strong>in</strong>c ash particle<br />

size on the z<strong>in</strong>c yield no significant<br />

effect was observed <strong>in</strong> the range of<br />

these fractions. On the basis of the<br />

results, as well as the observation<br />

with the eye, a higher yield was <strong>de</strong>tected<br />

<strong>in</strong> the f<strong>in</strong>est gra<strong>in</strong> size fraction<br />

with d < 0.125 mm than <strong>in</strong> other fractions.<br />

In that fraction almost all z<strong>in</strong>c<br />

is leached. The extracted extract with<br />

the high z<strong>in</strong>c content is suitable for<br />

further process<strong>in</strong>g <strong>in</strong> or<strong>de</strong>r to obta<strong>in</strong><br />

z<strong>in</strong>c. A suitable method is the electrolytic<br />

extraction after tak<strong>in</strong>g steps<br />

of the ref<strong>in</strong>ery and z<strong>in</strong>c carbonate<br />

precipitation.<br />

Acknowledgment<br />

This work was supported by Slovak<br />

Grant Agency for Science VEGA<br />

1/0134/09.<br />

Fig. 4: The highest yield of Zn <strong>in</strong> 5, 10, 15 %<br />

HCl dur<strong>in</strong>g leach<strong>in</strong>g time of 60 m<strong>in</strong> with gra<strong>in</strong><br />

of ash No. 3, at ambient temperature<br />

References<br />

[1] International z<strong>in</strong>c association. Available<br />

on Internet: < http://www.iza.com/<br />

recycl<strong>in</strong>g.html>.<br />

[2] HAVŘÁNKOVÁ, Z.: Žárové z<strong>in</strong>kování<br />

ponorem - Základní <strong>in</strong>formace pro<br />

uživatele. In: Konstrukce, 3, 2005.<br />

[3] KRIŠTOFOVÁ, D.: Recyklace<br />

neželezných kovů. Ostrava, 2003. s. 24-<br />

<strong>26</strong>. ISBN 80-248-0485-9.<br />

[4] Vyhláška č. 284/2001 Z.z. M<strong>in</strong>isterstva<br />

životného prostredia Slovenskej republiky,<br />

ktorou sa ustanovuje katalóg odpadov.<br />

Available on Internet: .<br />

[5] BARAKAT, M.A.: Pyrometallurgical<br />

process<strong>in</strong>g of z<strong>in</strong>c ash and flue dust. In:<br />

Acta <strong>Metall</strong>urgica Slovaca, 9, 2003, s.<br />

259-<strong>26</strong>9.<br />

[6] DVOŘÁK, P. - JANDOVÁ, J.: Z<strong>in</strong>c<br />

recovery from chlori<strong>de</strong>-bear<strong>in</strong>g galvaniz<strong>in</strong>g<br />

waste. In: Acta <strong>Metall</strong>urgica<br />

Slovaca, 12, 2006, s. 90-94.<br />

[7] The Nachi Dross Skimm<strong>in</strong>g Robot for<br />

Strip Galvaniz<strong>in</strong>g L<strong>in</strong>es. Available on<br />

Internet: .<br />

[8] VOURLIAS, G. et. al.: Study of the<br />

structure of hot-dip galvaniz<strong>in</strong>g byproducts.<br />

In: Journal of optoelectronics<br />

and advanced materials, 9, 2007, p.<br />

2937-2942.<br />

[9] Metaullics systems for z<strong>in</strong>c and galvaniz<strong>in</strong>g.<br />

Available on Internet: .<br />

[10] TAKÁČOVÁ, Z.: Diplomová práca:<br />

Možnosti spracovania z<strong>in</strong>kového<br />

popola vznikajúceho pri žiarovom<br />

poz<strong>in</strong>kovaní, Košice, 2009, s. 37 – 49.<br />

(1) Technical University of Knosice,<br />

Fakulty of <strong>Metall</strong>urgy, Department<br />

of Non-Ferrous Metals and<br />

Waste Treatment, Letná 9, 042 00<br />

Košice, Slovensko<br />

12/<strong>2010</strong> | 64. Jahrgang | METALL