Institut za rudarstvo i metalurgiju Bor

Institut za rudarstvo i metalurgiju Bor

Institut za rudarstvo i metalurgiju Bor

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

copper ores, that is, now, almost exclusively<br />

copper concentrates (with the previous<br />

agglomerations) are: SiO2, FeO, Fe2O3<br />

and MgO. In addition to thesecomponents,<br />

slag often contains: Fe3O4, BaO, ZnO,<br />

Cu2S, and almost always fine droplets of<br />

mechanically affected matte (copper<br />

matte). The composition of slag may not<br />

correspond to the chemical compounds:<br />

for example, FeO in slag may be present in<br />

a form of fayalite (FeO)2SiO2, but the excess<br />

of free FeO in basic slags may be also<br />

dissolved in fayalite.<br />

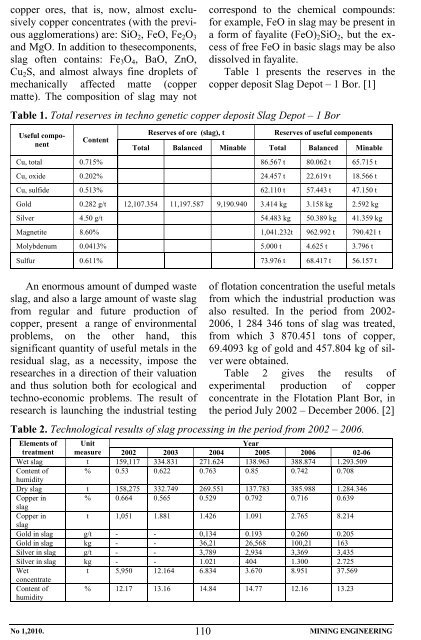

Table 1 presents the reserves in the<br />

copper deposit Slag Depot – 1 <strong>Bor</strong>. [1]<br />

Table 1. Total reserves in techno genetic copper deposit Slag Depot – 1 <strong>Bor</strong><br />

Useful component<br />

Content<br />

Reserves of ore (slag), t Reserves of useful components<br />

Total Balanced Minable Total Balanced Minable<br />

Cu, total 0.715% 86.567 t 80.062 t 65.715 t<br />

Cu, oxide 0.202% 24.457 t 22.619 t 18.566 t<br />

Cu, sulfide 0.513% 62.110 t 57.443 t 47.150 t<br />

Gold 0.282 g/t 12,107.354 11,197.587 9,190.940 3.414 kg 3.158 kg 2.592 kg<br />

Silver 4.50 g/t 54.483 kg 50.389 kg 41.359 kg<br />

Magnetite 8.60% 1,041.232t 962.992 t 790.421 t<br />

Molybdenum 0.0413% 5.000 t 4.625 t 3.796 t<br />

Sulfur 0.611% 73.976 t 68.417 t 56.157 t<br />

An enormous amount of dumped waste<br />

slag, and also a large amount of waste slag<br />

from regular and future production of<br />

copper, present a range of environmental<br />

problems, on the other hand, this<br />

significant quantity of useful metals in the<br />

residual slag, as a necessity, impose the<br />

researches in a direction of their valuation<br />

and thus solution both for ecological and<br />

techno-economic problems. The result of<br />

research is launching the industrial testing<br />

of flotation concentration the useful metals<br />

from which the industrial production was<br />

also resulted. In the period from 2002-<br />

2006, 1 284 346 tons of slag was treated,<br />

from which 3 870.451 tons of copper,<br />

69.4093 kg of gold and 457.804 kg of silver<br />

were obtained.<br />

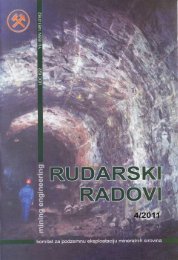

Table 2 gives the results of<br />

experimental production of copper<br />

concentrate in the Flotation Plant <strong>Bor</strong>, in<br />

the period July 2002 – December 2006. [2]<br />

Table 2. Technological results of slag processing in the period from 2002 – 2006.<br />

Elements of Unit<br />

Year<br />

treatment measure 2002 2003 2004 2005 2006 02-06<br />

Wet slag t 159,117 334.831 271.624 138.963 388.874 1.293.509<br />

Content of<br />

humidity<br />

% 0.53 0.622 0.763 0.85 0.742 0.708<br />

Dry slag t 158,275 332.749 269.551 137.783 385.988 1.284.346<br />

Copper in<br />

slag<br />

% 0.664 0.565 0.529 0.792 0.716 0.639<br />

Copper in<br />

slag<br />

t 1,051 1.881 1.426 1.091 2.765 8.214<br />

Gold in slag g/t - - 0,134 0.193 0.260 0.205<br />

Gold in slag kg - - 36,21 26,568 100,21 163<br />

Silver in slag g/t - - 3,789 2,934 3,369 3,435<br />

Silver in slag kg - - 1.021 404 1.300 2.725<br />

Wet<br />

concentrate<br />

t 5,950 12.164 6.834 3.670 8.951 37.569<br />

Content of<br />

humidity<br />

% 12.17 13.16 14.84 14.77 12.16 13.23<br />

No 1,2010. 110<br />

MINING ENGINEERING