Institut za rudarstvo i metalurgiju Bor

Institut za rudarstvo i metalurgiju Bor

Institut za rudarstvo i metalurgiju Bor

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

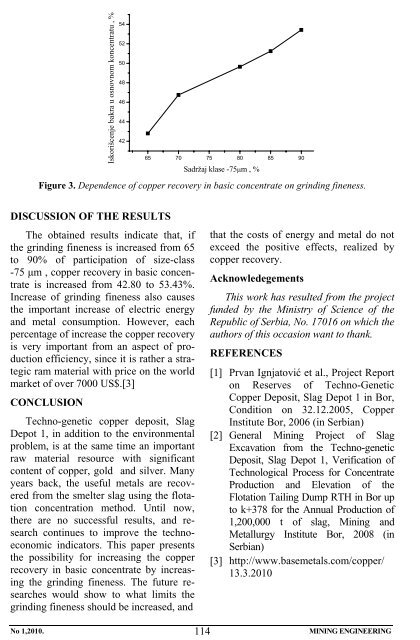

Iskorišcenje bakra u osnovnom koncentratu , %<br />

54<br />

52<br />

50<br />

48<br />

46<br />

44<br />

42<br />

65 70 75 80 85 90<br />

Sadržaj klase -75μm , %<br />

Figure 3. Dependence of copper recovery in basic concentrate on grinding fineness.<br />

DISCUSSION OF THE RESULTS<br />

The obtained results indicate that, if<br />

the grinding fineness is increased from 65<br />

to 90% of participation of size-class<br />

-75 μm , copper recovery in basic concentrate<br />

is increased from 42.80 to 53.43%.<br />

Increase of grinding fineness also causes<br />

the important increase of electric energy<br />

and metal consumption. However, each<br />

percentage of increase the copper recovery<br />

is very important from an aspect of production<br />

efficiency, since it is rather a strategic<br />

ram material with price on the world<br />

market of over 7000 US$.[3]<br />

CONCLUSION<br />

Techno-genetic copper deposit, Slag<br />

Depot 1, in addition to the environmental<br />

problem, is at the same time an important<br />

raw material resource with significant<br />

content of copper, gold and silver. Many<br />

years back, the useful metals are recovered<br />

from the smelter slag using the flotation<br />

concentration method. Until now,<br />

there are no successful results, and research<br />

continues to improve the technoeconomic<br />

indicators. This paper presents<br />

the possibility for increasing the copper<br />

recovery in basic concentrate by increasing<br />

the grinding fineness. The future researches<br />

would show to what limits the<br />

grinding fineness should be increased, and<br />

that the costs of energy and metal do not<br />

exceed the positive effects, realized by<br />

copper recovery.<br />

Acknowledegements<br />

This work has resulted from the project<br />

funded by the Ministry of Science of the<br />

Republic of Serbia, No. 17016 on which the<br />

authors of this occasion want to thank.<br />

REFERENCES<br />

[1] Prvan Ignjatović et al., Project Report<br />

on Reserves of Techno-Genetic<br />

Copper Deposit, Slag Depot 1 in <strong>Bor</strong>,<br />

Condition on 32.12.2005, Copper<br />

<strong>Institut</strong>e <strong>Bor</strong>, 2006 (in Serbian)<br />

[2] General Mining Project of Slag<br />

Excavation from the Techno-genetic<br />

Deposit, Slag Depot 1, Verification of<br />

Technological Process for Concentrate<br />

Production and Elevation of the<br />

Flotation Tailing Dump RTH in <strong>Bor</strong> up<br />

to k+378 for the Annual Production of<br />

1,200,000 t of slag, Mining and<br />

Metallurgy <strong>Institut</strong>e <strong>Bor</strong>, 2008 (in<br />

Serbian)<br />

[3] http://www.basemetals.com/copper/<br />

13.3.2010<br />

No 1,2010. 114<br />

MINING ENGINEERING