Voltage References

Voltage References

Voltage References

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Quality improvement for a task or a process can be quickly<br />

described in terms of the target, current status with respect to<br />

target (variability), reduction of variability (commitment to<br />

never ending improvement), customer requirements (who<br />

receives output, what are a person's requirements/<br />

expectations) and economics (cost of nonconformance, loss<br />

function, etc.).<br />

Application of quality to the whole company has come to be<br />

known by such names as "Total Quality Control" (TQC);<br />

"Company Wide Quality Control" (CWQC); "Total Quality<br />

Excellence" or "Total Quality Engineering" (TQE); "Total<br />

Quality Involvement" (TQI). These names attempt to convey<br />

the idea that quality is a process (a way of acting continuously)<br />

rather than a program (implying a beginning and an end).<br />

Nevertheless for this process to be successful it must be able<br />

to show measurable results.<br />

"Six Sigma is the required capability level to approach the<br />

standard. The standard is zero defects. Our goal is to be<br />

Best-in-Class in product, sales and service." (For a more<br />

detailed explanation, contact your Motorola Representative<br />

for a pamphlet of the Six Sigma Challenge.)<br />

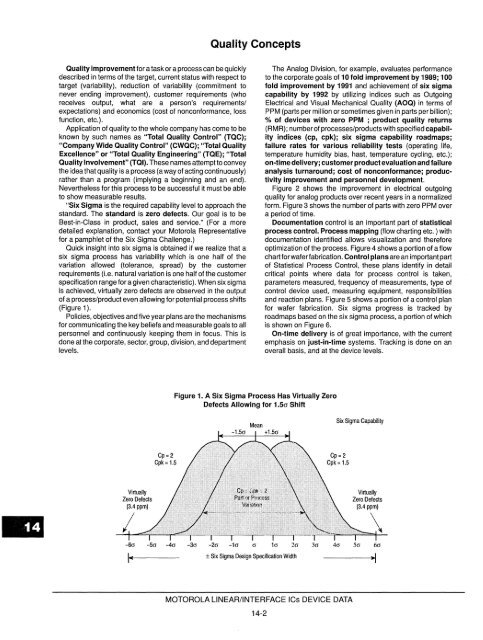

Quick insight into six sigma is obtained if we realize that a<br />

six sigma process has variability which is one half of the<br />

variation allowed (tolerance, spread) by the customer<br />

requirements (i.e. natural variation is one half of the customer<br />

specification range for a given characteristic). When six sigma<br />

is achieved, virtually zero defects are observed in the output<br />

of a process/product even allowing for potential process shifts<br />

(Figure 1).<br />

Policies, objectives and five year plans are the mechanisms<br />

for communicating the key beliefs and measurable goals to all<br />

personnel and continuously keeping them in focus. This is<br />

done at the corporate, sector, group, division, and department<br />

levels.<br />

Virtually<br />

Zero Defects<br />

(3.4 ppm)<br />

I<br />

Cp = 2<br />

Cpk=I.5<br />

Quality Concepts<br />

Figure 1. A Six Sigma Process Has Virtually Zero<br />

Defects Allowing for 1.50" Shift<br />

The Analog Division, for example, evaluates performance<br />

to the corporate goals of 10 fold improvement by 1989; 100<br />

fold improvement by 1991 and achievement of six sigma<br />

capability by 1992 by utilizing indices such as Outgoing<br />

Electrical and Visual Mechanical Quality (AOQ) in terms of<br />

PPM (parts per million or sometimes given in parts per billion);<br />

% of devices with zero PPM ; product quality returns<br />

(RMR); number of processes/products with specified capability<br />

indices (cp, cpk); six sigma capability roadmaps;<br />

failure rates for various reliability tests (operating life,<br />

temperature humidity bias, hast, temperature cycling, etc.);<br />

on-time delivery; customer product evaluation and failure<br />

analysis turnaround; cost of nonconformance; productivity<br />

improvement and personnel development.<br />

Figure 2 shows the improvement in electrical outgoing<br />

quality for analog products over recent years in a normalized<br />

form. Figure 3 shows the number of parts with zero PPM over<br />

a period of time.<br />

Documentation control is an important part of statistical<br />

process control. Process mapping (flow charting etc. ) with<br />

documentation identified allows visualization and therefore<br />

optimization of the process. Figure 4 shows a portion of a flow<br />

chartforwaferfabrication. Control plans are an important part<br />

of Statistical Process Control, these plans identify in detail<br />

critical points where data for process control is taken,<br />

parameters measured, frequency of measurements, type of<br />

control device used, measuring equipment, responsibilities<br />

and reaction plans. Figure 5 shows a portion of a control plan<br />

for wafer fabrication. Six sigma progress is tracked by<br />

roadmaps based on the six sigma process, a portion of which<br />

is shown on Figure 6.<br />

On-time delivery is of great importance, with the current<br />

emphasis on just-in-time systems. Tracking is done on an<br />

overall basis, and at the device levels.<br />

Six Sigma Capability<br />

Cp = 2<br />

Cpk = 1.5<br />

-60" -50" -40" -30" -20" -10 0" 10" 20 30" 40"<br />

± Six Sigma Design Specification Width<br />

MOTOROLA LINEAR/INTERFACE ICs DEVICE DATA<br />

14-2<br />

50" 60"