A new face drilling rig for narrow tunnels and ... - Advanced Mining

A new face drilling rig for narrow tunnels and ... - Advanced Mining

A new face drilling rig for narrow tunnels and ... - Advanced Mining

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

at l a s Co p C o Un d e r g ro U n d ro C k ex C a v a t i o n<br />

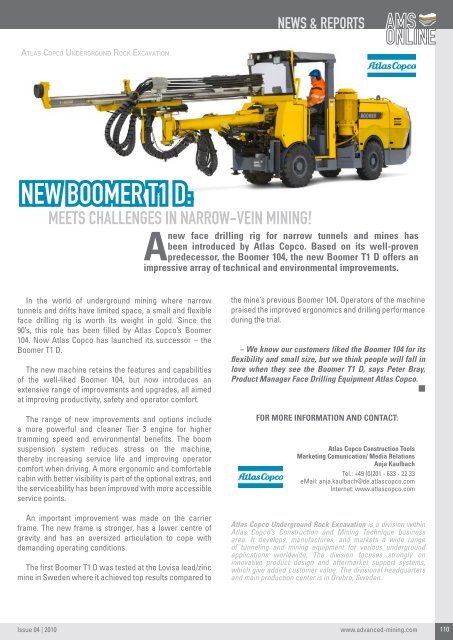

NEW BOOMER T1 D:<br />

Issue 04 | 2010<br />

MEETS CHALLENGES IN NARROW-VEIN MINING!<br />

A<br />

In the world of underground mining where <strong>narrow</strong><br />

<strong>tunnels</strong> <strong>and</strong> drifts have limited space, a small <strong>and</strong> flexible<br />

<strong>face</strong> <strong>drilling</strong> <strong>rig</strong> is worth its weight in gold. Since the<br />

90’s, this role has been filled by Atlas Copco’s Boomer<br />

104. Now Atlas Copco has launched its successor – the<br />

Boomer T1 D.<br />

The <strong>new</strong> machine retains the features <strong>and</strong> capabilities<br />

of the well-liked Boomer 104, but now introduces an<br />

extensive range of improvements <strong>and</strong> upgrades, all aimed<br />

at improving productivity, safety <strong>and</strong> operator com<strong>for</strong>t.<br />

The range of <strong>new</strong> improvements <strong>and</strong> options include<br />

a more powerful <strong>and</strong> cleaner Tier 3 engine <strong>for</strong> higher<br />

tramming speed <strong>and</strong> environmental benefits. The boom<br />

suspension system reduces stress on the machine,<br />

thereby increasing service life <strong>and</strong> improving operator<br />

com<strong>for</strong>t when driving. A more ergonomic <strong>and</strong> com<strong>for</strong>table<br />

cabin with better visibility is part of the optional extras, <strong>and</strong><br />

the serviceability has been improved with more accessible<br />

service points.<br />

An important improvement was made on the carrier<br />

frame. The <strong>new</strong> frame is stronger, has a lower centre of<br />

gravity <strong>and</strong> has an oversized articulation to cope with<br />

dem<strong>and</strong>ing operating conditions.<br />

The first Boomer T1 D was tested at the Lovisa lead/zinc<br />

mine in Sweden where it achieved top results compared to<br />

NEWS & REPORTS<br />

<strong>new</strong> <strong>face</strong> <strong>drilling</strong> <strong>rig</strong> <strong>for</strong> <strong>narrow</strong> <strong>tunnels</strong> <strong>and</strong> mines has<br />

been introduced by Atlas Copco. Based on its well-proven<br />

predecessor, the Boomer 104, the <strong>new</strong> Boomer T1 D offers an<br />

impressive array of technical <strong>and</strong> environmental improvements.<br />

the mine’s previous Boomer 104. Operators of the machine<br />

praised the improved ergonomics <strong>and</strong> <strong>drilling</strong> per<strong>for</strong>mance<br />

during the trial.<br />

– We know our customers liked the Boomer 104 <strong>for</strong> its<br />

flexibility <strong>and</strong> small size, but we think people will fall in<br />

love when they see the Boomer T1 D, says Peter Bray,<br />

Product Manager Face Drilling Equipment Atlas Copco.<br />

FOR MORE INFORMATION AND CONTACT:<br />

Atlas Copco Construction Tools<br />

Marketing Comunication/ Media Relations<br />

Anja Kaulbach<br />

Tel.: +49 (0)201 - 633 - 22 33<br />

eMail: anja.kaulbach@de.atlascopco.com<br />

Internet: www.atlascopco.com<br />

Atlas Copco Underground Rock Excavation is a division within<br />

Atlas Copco’s Construction <strong>and</strong> <strong>Mining</strong> Technique business<br />

area. It develops, manufactures, <strong>and</strong> markets a wide range<br />

of tunneling <strong>and</strong> mining equipment <strong>for</strong> various underground<br />

applications worldwide. The division focuses strongly on<br />

innovative product design <strong>and</strong> aftermarket support systems,<br />

which give added customer value. The divisional headquarters<br />

<strong>and</strong> main production center is in Örebro, Sweden..<br />

www.advanced-mining.com<br />

110