A new face drilling rig for narrow tunnels and ... - Advanced Mining

A new face drilling rig for narrow tunnels and ... - Advanced Mining

A new face drilling rig for narrow tunnels and ... - Advanced Mining

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Having neglected the very complex sound diffusivity,<br />

whose treatment requires the use of a specialized software,<br />

however, it is enabled the admissible sound power of the<br />

<strong>new</strong> coal logistics to be assessed, even with the aid of<br />

simple means.<br />

The sound power levels shown in the table, <strong>and</strong><br />

calculated on the basis of the admissible sound pressure<br />

levels at the places of immission would only be accepted,<br />

if the plant could be considered point sound source. But<br />

since the individual machines <strong>and</strong> plant components are<br />

spread over a large sur<strong>face</strong>, the influence individual sound<br />

sources have on different places of immission is highly<br />

varying. That is why the part in the sound pressure the<br />

slewing crane in the port has at the place of immission 1<br />

will be far bigger than that at the place of immission 2 or<br />

3. So, the position <strong>and</strong> distribution of the individual noise<br />

sources need to be taken into account when fixing their<br />

maximally admissible sound power levels. That is the<br />

direct consequence of the closeness of residential areas<br />

to the plant. It can be made a rule, as <strong>for</strong>mulated in the VDI<br />

2714 no longer valid today, that an accumulation of noise<br />

sources can be considered point sound source then, if the<br />

distance from the centre point of the noise sources will be<br />

at least twice the diameter of the circle surrounding the<br />

noise sources.<br />

Structure of the plant<br />

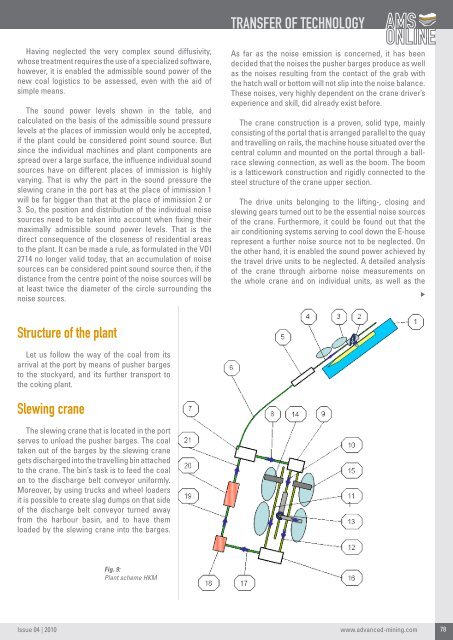

Let us follow the way of the coal from its<br />

arrival at the port by means of pusher barges<br />

to the stockyard, <strong>and</strong> its further transport to<br />

the coking plant.<br />

Slewing crane<br />

The slewing crane that is located in the port<br />

serves to unload the pusher barges. The coal<br />

taken out of the barges by the slewing crane<br />

gets discharged into the travelling bin attached<br />

to the crane. The bin’s task is to feed the coal<br />

on to the discharge belt conveyor uni<strong>for</strong>mly.<br />

Moreover, by using trucks <strong>and</strong> wheel loaders<br />

it is possible to create slag dumps on that side<br />

of the discharge belt conveyor turned away<br />

from the harbour basin, <strong>and</strong> to have them<br />

loaded by the slewing crane into the barges.<br />

Issue 04 | 2010<br />

Fig. 9:<br />

Plant scheme HKM<br />

TRANSFER OF TECHNOLOGY<br />

As far as the noise emission is concerned, it has been<br />

decided that the noises the pusher barges produce as well<br />

as the noises resulting from the contact of the grab with<br />

the hatch wall or bottom will not slip into the noise balance.<br />

These noises, very highly dependent on the crane driver’s<br />

experience <strong>and</strong> skill, did already exist be<strong>for</strong>e.<br />

The crane construction is a proven, solid type, mainly<br />

consisting of the portal that is arranged parallel to the quay<br />

<strong>and</strong> travelling on rails, the machine house situated over the<br />

central column <strong>and</strong> mounted on the portal through a ballrace<br />

slewing connection, as well as the boom. The boom<br />

is a latticework construction <strong>and</strong> <strong>rig</strong>idly connected to the<br />

steel structure of the crane upper section.<br />

The drive units belonging to the lifting-, closing <strong>and</strong><br />

slewing gears turned out to be the essential noise sources<br />

of the crane. Furthermore, it could be found out that the<br />

air conditioning systems serving to cool down the E-house<br />

represent a further noise source not to be neglected. On<br />

the other h<strong>and</strong>, it is enabled the sound power achieved by<br />

the travel drive units to be neglected. A detailed analysis<br />

of the crane through airborne noise measurements on<br />

the whole crane <strong>and</strong> on individual units, as well as the<br />

www.advanced-mining.com<br />

78