BOGIES AND SUSPENSION - South Central Railway

BOGIES AND SUSPENSION - South Central Railway

BOGIES AND SUSPENSION - South Central Railway

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

CHAPTER 6 – <strong>BOGIES</strong> <strong>AND</strong> <strong>SUSPENSION</strong><br />

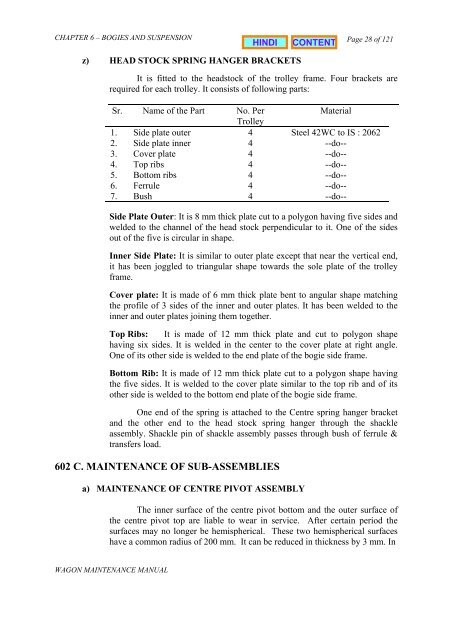

z) HEAD STOCK SPRING HANGER BRACKETS<br />

WAGON MAINTENANCE MANUAL<br />

Page 28 of 121<br />

It is fitted to the headstock of the trolley frame. Four brackets are<br />

required for each trolley. It consists of following parts:<br />

Sr. Name of the Part No. Per<br />

Trolley<br />

Material<br />

1. Side plate outer 4 Steel 42WC to IS : 2062<br />

2. Side plate inner 4 --do--<br />

3. Cover plate 4 --do--<br />

4. Top ribs 4 --do--<br />

5. Bottom ribs 4 --do--<br />

6. Ferrule 4 --do--<br />

7. Bush 4 --do--<br />

Side Plate Outer: It is 8 mm thick plate cut to a polygon having five sides and<br />

welded to the channel of the head stock perpendicular to it. One of the sides<br />

out of the five is circular in shape.<br />

Inner Side Plate: It is similar to outer plate except that near the vertical end,<br />

it has been joggled to triangular shape towards the sole plate of the trolley<br />

frame.<br />

Cover plate: It is made of 6 mm thick plate bent to angular shape matching<br />

the profile of 3 sides of the inner and outer plates. It has been welded to the<br />

inner and outer plates joining them together.<br />

Top Ribs: It is made of 12 mm thick plate and cut to polygon shape<br />

having six sides. It is welded in the center to the cover plate at right angle.<br />

One of its other side is welded to the end plate of the bogie side frame.<br />

Bottom Rib: It is made of 12 mm thick plate cut to a polygon shape having<br />

the five sides. It is welded to the cover plate similar to the top rib and of its<br />

other side is welded to the bottom end plate of the bogie side frame.<br />

One end of the spring is attached to the Centre spring hanger bracket<br />

and the other end to the head stock spring hanger through the shackle<br />

assembly. Shackle pin of shackle assembly passes through bush of ferrule &<br />

transfers load.<br />

602 C. MAINTENANCE OF SUB-ASSEMBLIES<br />

a) MAINTENANCE OF CENTRE PIVOT ASSEMBLY<br />

The inner surface of the centre pivot bottom and the outer surface of<br />

the centre pivot top are liable to wear in service. After certain period the<br />

surfaces may no longer be hemispherical. These two hemispherical surfaces<br />

have a common radius of 200 mm. It can be reduced in thickness by 3 mm. In