BOGIES AND SUSPENSION - South Central Railway

BOGIES AND SUSPENSION - South Central Railway

BOGIES AND SUSPENSION - South Central Railway

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

CHAPTER 6 – <strong>BOGIES</strong> <strong>AND</strong> <strong>SUSPENSION</strong><br />

WAGON MAINTENANCE MANUAL<br />

Page 86 of 121<br />

The ovalty and taper on the journal should be within the permissible limit of<br />

0.1 mm. The ovalty and taper of the journal should be checked by measuring the<br />

diameter with micrometer at 3 locations both on the vertical and horizontal axis. If<br />

required, measurements at more locations should also be taken. If cases of ovalty and<br />

taper going beyond the permissible limits, are detected, the grinding and burnishing<br />

machine should be checked and its defects should be rectified. Cent percent check for<br />

ovality and taper should be carried out. Diameter of all journals coming one of the<br />

wheel shop should be measured & a record be maintained. The dia of the journal<br />

should be written with chalk on inner surface of the wheel for guidance of the staff in<br />

the lifting section. The top surface of the outer collar, where necessary, must be<br />

finished by a suitable form tool either on grinding or burnishing machines or on<br />

another suitable lathe.<br />

As indicated above, normally the minimum length of the journal for a<br />

particular step size diameter is automatically re-ensured. However, there may be<br />

exception and the minimum length of the journal should, therefore, be checked by<br />

means of a gauge.<br />

Wheels which are required to be send to out stations after repair or which are<br />

required to be kept in spare pool, for some days, should be carefully painted with 3<br />

coats of bituminous solution to IS : Specification No. 158. To protect the journal<br />

surface of the wheels being sent to out stations against mechanical damage, it should<br />

be fitted with tightly bound wood lagging extending outside the collar and up to<br />

wheel seat, completely surrounding the journal.<br />

Concentricity of the journal and wheel tread is an important matter for<br />

satisfactory performance of the bearings and this should be occasionally checked<br />

when wheels are attended to in shop or in sick lines.<br />

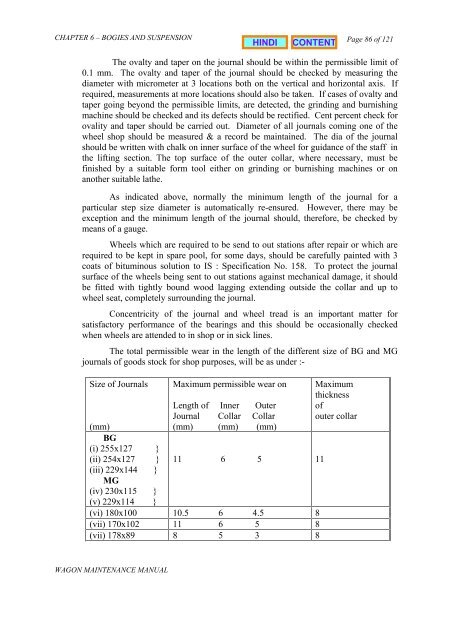

The total permissible wear in the length of the different size of BG and MG<br />

journals of goods stock for shop purposes, will be as under :-<br />

Size of Journals<br />

Maximum permissible wear on<br />

Length of Inner Outer<br />

Journal Collar Collar<br />

(mm) (mm) (mm)<br />

(mm)<br />

BG<br />

(i) 255x127 }<br />

(ii) 254x127 }<br />

(iii) 229x144 }<br />

MG<br />

(iv) 230x115 }<br />

(v) 229x114 }<br />

11 6 5 11<br />

(vi) 180x100 10.5 6 4.5 8<br />

(vii) 170x102 11 6 5 8<br />

(vii) 178x89 8 5 3 8<br />

Maximum<br />

thickness<br />

of<br />

outer collar