BOGIES AND SUSPENSION - South Central Railway

BOGIES AND SUSPENSION - South Central Railway

BOGIES AND SUSPENSION - South Central Railway

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

CHAPTER 6 – <strong>BOGIES</strong> <strong>AND</strong> <strong>SUSPENSION</strong><br />

B 1<br />

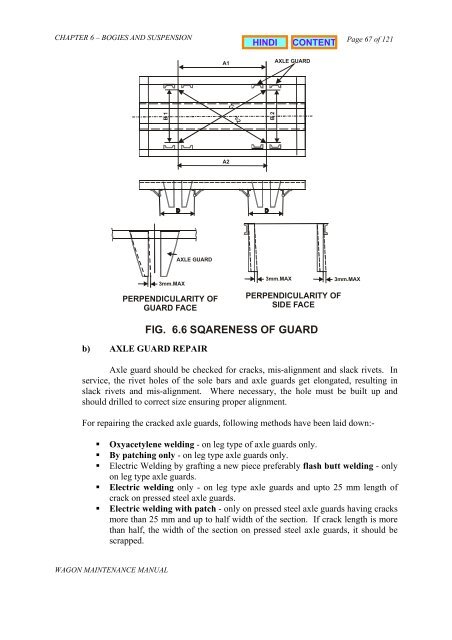

b) AXLE GUARD REPAIR<br />

WAGON MAINTENANCE MANUAL<br />

3mm.MAX<br />

AXLE GUARD<br />

PERPENDICULARITY OF<br />

GUARD FACE<br />

A1<br />

C1<br />

A2<br />

AXLE GUARD<br />

FIG. 6.6 SQARENESS OF GUARD<br />

Page 67 of 121<br />

Axle guard should be checked for cracks, mis-alignment and slack rivets. In<br />

service, the rivet holes of the sole bars and axle guards get elongated, resulting in<br />

slack rivets and mis-alignment. Where necessary, the hole must be built up and<br />

should drilled to correct size ensuring proper alignment.<br />

For repairing the cracked axle guards, following methods have been laid down:-<br />

c2<br />

Oxyacetylene welding - on leg type of axle guards only.<br />

By patching only - on leg type axle guards only.<br />

Electric Welding by grafting a new piece preferably flash butt welding - only<br />

on leg type axle guards.<br />

Electric welding only - on leg type axle guards and upto 25 mm length of<br />

crack on pressed steel axle guards.<br />

Electric welding with patch - only on pressed steel axle guards having cracks<br />

more than 25 mm and up to half width of the section. If crack length is more<br />

than half, the width of the section on pressed steel axle guards, it should be<br />

scrapped.<br />

B 2<br />

3mm.MAX 3mm.MAX<br />

PERPENDICULARITY OF<br />

SIDE FACE