BOGIES AND SUSPENSION - South Central Railway

BOGIES AND SUSPENSION - South Central Railway

BOGIES AND SUSPENSION - South Central Railway

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

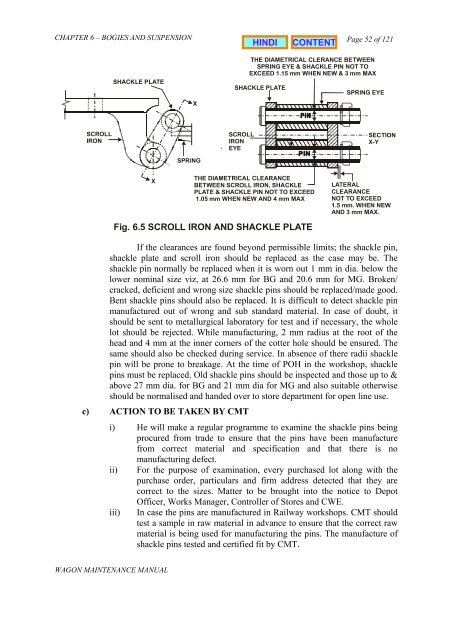

CHAPTER 6 – <strong>BOGIES</strong> <strong>AND</strong> <strong>SUSPENSION</strong><br />

SCROLL<br />

IRON<br />

SHACKLE PLATE<br />

WAGON MAINTENANCE MANUAL<br />

X<br />

X<br />

SPRING<br />

SHACKLE PLATE<br />

SCROLL<br />

IRON<br />

EYE<br />

THE DIAMETRICAL CLEARANCE<br />

BETWEEN SCROLL IRON, SHACKLE<br />

PLATE & SHACKLE PIN NOT TO EXCEED<br />

1.05 mm WHEN NEW <strong>AND</strong> 4 mm MAX<br />

Fig. 6.5 SCROLL IRON <strong>AND</strong> SHACKLE PLATE<br />

Page 52 of 121<br />

THE DIAMETRICAL CLERANCE BETWEEN<br />

SPRING EYE & SHACKLE PIN NOT TO<br />

EXCEED 1.15 mm WHEN NEW & 3 mm MAX<br />

SPRING EYE<br />

SECTION<br />

X-Y<br />

LATERAL<br />

CLEARANCE<br />

NOT TO EXCEED<br />

1.5 mm. WHEN NEW<br />

<strong>AND</strong> 3 mm MAX.<br />

If the clearances are found beyond permissible limits; the shackle pin,<br />

shackle plate and scroll iron should be replaced as the case may be. The<br />

shackle pin normally be replaced when it is worn out 1 mm in dia. below the<br />

lower nominal size viz, at 26.6 mm for BG and 20.6 mm for MG. Broken/<br />

cracked, deficient and wrong size shackle pins should be replaced/made good.<br />

Bent shackle pins should also be replaced. It is difficult to detect shackle pin<br />

manufactured out of wrong and sub standard material. In case of doubt, it<br />

should be sent to metallurgical laboratory for test and if necessary, the whole<br />

lot should be rejected. While manufacturing, 2 mm radius at the root of the<br />

head and 4 mm at the inner corners of the cotter hole should be ensured. The<br />

same should also be checked during service. In absence of there radii shackle<br />

pin will be prone to breakage. At the time of POH in the workshop, shackle<br />

pins must be replaced. Old shackle pins should be inspected and those up to &<br />

above 27 mm dia. for BG and 21 mm dia for MG and also suitable otherwise<br />

should be normalised and handed over to store department for open line use.<br />

c) ACTION TO BE TAKEN BY CMT<br />

i) He will make a regular programme to examine the shackle pins being<br />

procured from trade to ensure that the pins have been manufacture<br />

from correct material and specification and that there is no<br />

manufacturing defect.<br />

ii) For the purpose of examination, every purchased lot along with the<br />

purchase order, particulars and firm address detected that they are<br />

correct to the sizes. Matter to be brought into the notice to Depot<br />

Officer, Works Manager, Controller of Stores and CWE.<br />

iii) In case the pins are manufactured in <strong>Railway</strong> workshops. CMT should<br />

test a sample in raw material in advance to ensure that the correct raw<br />

material is being used for manufacturing the pins. The manufacture of<br />

shackle pins tested and certified fit by CMT.