BOGIES AND SUSPENSION - South Central Railway

BOGIES AND SUSPENSION - South Central Railway

BOGIES AND SUSPENSION - South Central Railway

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

CHAPTER 6 – <strong>BOGIES</strong> <strong>AND</strong> <strong>SUSPENSION</strong><br />

g) SPRING<br />

WAGON MAINTENANCE MANUAL<br />

Page 54 of 121<br />

It is a laminated bearing made out of a number of spring steel plates of<br />

different lengths fastened together in the centre by means of buckle and other<br />

fastenings. Plates are nibbed at suitable locations or have “rib and groove”<br />

section. On some BG springs a few plates are clamped together near both the<br />

ends by means of clips and its fastenings. Similar clamping has been recently<br />

been introduced on MG spring also. The top plate is rolled at the both ends to<br />

form an eye which receives the shackle pin.<br />

Bearing spring is a medium of transmitting wagon weight including<br />

consignment to the axle box. Any defect in the bearing spring would lead to<br />

undesirable loading of axle box and the bearing brass resulting in derailment<br />

or hot box. Bearing springs on both the ends are connected with the wagon<br />

underframe through the shackle pins, shackle plates and scroll iron. The<br />

central portion sits on the axle box crown.<br />

Springs are manufactured/ repaired in the workshops. It involves<br />

proper heat treatment, inspection and testing. The springs should not be<br />

repaired on open line where adequate repair facilities does not exists. On open<br />

line, inspection and checking of camber of springs should be done, and<br />

defective springs should be replaced.<br />

There are various types and sizes of springs in used on wagons, as<br />

different types of wagons were put on line from time to time. It is not possible<br />

to describe all types of spring here. Only standard types of springs are being<br />

described here. The factors causing difference in springs can be broadly<br />

classified as under:<br />

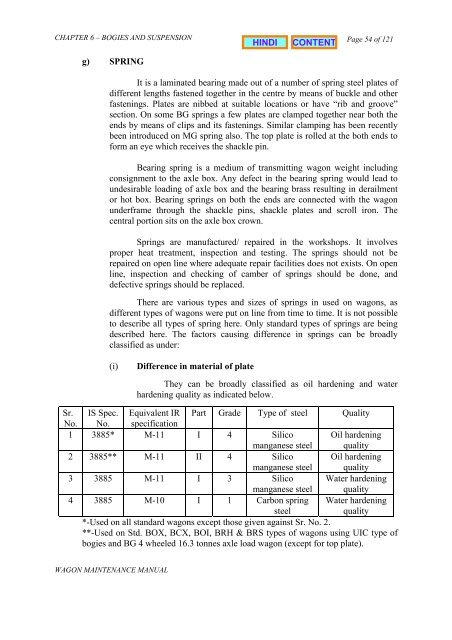

(i) Difference in material of plate<br />

They can be broadly classified as oil hardening and water<br />

hardening quality as indicated below.<br />

Sr. IS Spec. Equivalent IR Part Grade Type of steel Quality<br />

No. No. specification<br />

1 3885* M-11 I 4 Silico Oil hardening<br />

manganese steel quality<br />

2 3885** M-11 II 4 Silico Oil hardening<br />

manganese steel quality<br />

3 3885 M-11 I 3 Silico Water hardening<br />

manganese steel quality<br />

4 3885 M-10 I 1 Carbon spring Water hardening<br />

steel<br />

quality<br />

*-Used on all standard wagons except those given against Sr. No. 2.<br />

**-Used on Std. BOX, BCX, BOI, BRH & BRS types of wagons using UIC type of<br />

bogies and BG 4 wheeled 16.3 tonnes axle load wagon (except for top plate).