BOGIES AND SUSPENSION - South Central Railway

BOGIES AND SUSPENSION - South Central Railway

BOGIES AND SUSPENSION - South Central Railway

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

CHAPTER 6 – <strong>BOGIES</strong> <strong>AND</strong> <strong>SUSPENSION</strong><br />

WAGON MAINTENANCE MANUAL<br />

Page 84 of 121<br />

The particular step size of bearing should always be fitted on the<br />

corresponding step size journal. ‘B’ size bearing should not be fitted on ‘A’ size<br />

journal. The dia of ‘B’ size bearings less than it will rest against the journal on its side<br />

instead of at centre and will result in hot box. In extreme cases, step size ‘A’ bearing<br />

can be used on ‘B’ size journal and the ‘B’ size bearing on ‘C’ size journals. Care<br />

should, however, be exercised that length suits the journal for which lateral play<br />

should be checked. In no case, ‘C’ size bearing should be used on ‘B’ and ‘A’ size<br />

journals and ‘B’ size bearing on ‘A’ size journals.<br />

It is important to identify the step sizes of the bearing and journals.<br />

Identification color strips should be painted at one of the recesses on the top of the<br />

bearing brass to know its step size with following color scheme :-<br />

Step size ‘A’ - Green<br />

Step size ‘B’ - Yellow<br />

Step size ‘C’ - Red.<br />

Suitable span gauges should be used for measuring the diameter of the<br />

journals by which step size of journal can be decided. The length of the journal<br />

mostly falls within step size of the journal based on dia. The lateral play of the brass<br />

may be checked on a dummy journal or on a journal on which the brass will be used.<br />

The gauge to be used for checking the lateral play. Step size brasses, however ensure<br />

adequate initial lateral clearances. The prescribed minimum and maximum lateral<br />

play of the brasses is tabulated below:-<br />

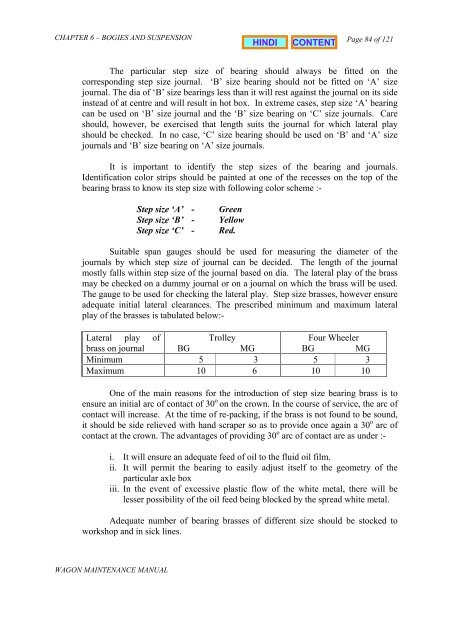

Lateral play of<br />

Trolley<br />

Four Wheeler<br />

brass on journal BG MG<br />

BG MG<br />

Minimum 5 3 5 3<br />

Maximum 10 6 10 10<br />

One of the main reasons for the introduction of step size bearing brass is to<br />

ensure an initial arc of contact of 30 o on the crown. In the course of service, the arc of<br />

contact will increase. At the time of re-packing, if the brass is not found to be sound,<br />

it should be side relieved with hand scraper so as to provide once again a 30 o arc of<br />

contact at the crown. The advantages of providing 30 o arc of contact are as under :-<br />

i. It will ensure an adequate feed of oil to the fluid oil film.<br />

ii. It will permit the bearing to easily adjust itself to the geometry of the<br />

particular axle box<br />

iii. In the event of excessive plastic flow of the white metal, there will be<br />

lesser possibility of the oil feed being blocked by the spread white metal.<br />

Adequate number of bearing brasses of different size should be stocked to<br />

workshop and in sick lines.