BOGIES AND SUSPENSION - South Central Railway

BOGIES AND SUSPENSION - South Central Railway

BOGIES AND SUSPENSION - South Central Railway

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

CHAPTER 6 – <strong>BOGIES</strong> <strong>AND</strong> <strong>SUSPENSION</strong><br />

603 E. REPAIR <strong>AND</strong> MAINTENANCE DURING ROH & POH<br />

WAGON MAINTENANCE MANUAL<br />

Page 44 of 121<br />

The following additional work also to be carried out during maintenance at<br />

the time of ROH and POH including the above repair work at sick line:-<br />

i. Bogie is to be fully dismantled.<br />

ii. Side frame should be examined for cracks, distortion, excessive pitting etc.<br />

iii. Longitudinal, transverse and diagonal distances of the journal centres should<br />

be checked to ascertain the squareness and correct alignment of the trolley.<br />

iv. <strong>Central</strong> distance of axle box holes and the diameter should be checked. Holes<br />

should be built up by welding & drilled to correct distance, when the dia<br />

exceeds by 2 mm above the nominal size.<br />

v. The steel bushes in the bracket of the brake beam hanger should be checked<br />

for wear and replaced when dia exceeds 0.75 mm above the nominal size.<br />

vi. The rivets of the spring plank and tie bar should be checked for soundness. It<br />

should be replaced if found unsound.<br />

vii. The alignment of the tie bar with corresponding top surface and side frame<br />

should be checked If found defective, it should be rectified.<br />

viii. There is one drain hole in each of the top extended portion, and two in bottom<br />

central portion of the side frame, these holes should be cleaned and kept clear.<br />

ix. Maintenance of spring plank is to be done as given in para 603C(b)<br />

x. Maintenance of floating bogie bolster is to be done as given in para 603C(c)<br />

xi. Maintenance of bogie centre pivot is to be done as given in para 603C(d)<br />

xii. Maintenance of bogie side bearer is to be done as given in para 603C(e)<br />

xiii. Maintenance of spring plate is to be done as given in para 603C(f)<br />

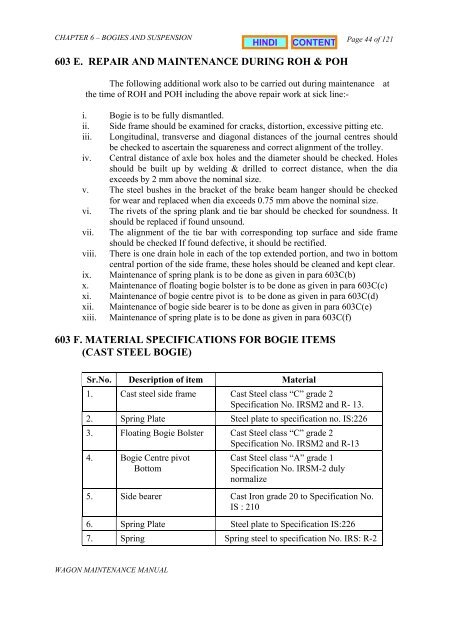

603 F. MATERIAL SPECIFICATIONS FOR BOGIE ITEMS<br />

(CAST STEEL BOGIE)<br />

Sr.No. Description of item Material<br />

1. Cast steel side frame Cast Steel class “C” grade 2<br />

Specification No. IRSM2 and R- 13.<br />

2. Spring Plate Steel plate to specification no. IS:226<br />

3. Floating Bogie Bolster Cast Steel class “C” grade 2<br />

Specification No. IRSM2 and R-13<br />

4. Bogie Centre pivot Cast Steel class “A” grade 1<br />

Bottom<br />

Specification No. IRSM-2 duly<br />

normalize<br />

5. Side bearer<br />

Cast Iron grade 20 to Specification No.<br />

IS : 210<br />

6. Spring Plate Steel plate to Specification IS:226<br />

7. Spring Spring steel to specification No. IRS: R-2