BOGIES AND SUSPENSION - South Central Railway

BOGIES AND SUSPENSION - South Central Railway

BOGIES AND SUSPENSION - South Central Railway

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

CHAPTER 6 – <strong>BOGIES</strong> <strong>AND</strong> <strong>SUSPENSION</strong><br />

WAGON MAINTENANCE MANUAL<br />

Page 90 of 121<br />

To be able to introduce the procedure mentioned above, 2 soaking tanks with<br />

perforated trays would be required, one for soaking new waste and the second for<br />

reclaimed waste and the requirement of shallow containers would be three, one for<br />

new soaked waste, another for reclaimed waste and the third for the mixed, new and<br />

reclaimed waste. This would be the minimum requirement and may be increased<br />

depending upon consumption of soaked waste. The steam heated vacuum waste<br />

soaking plant is an alternative to the conventional method for preparation of soaked<br />

waste, which is also in use on <strong>Railway</strong>s.<br />

The requisite quantity of cleared waste is placed in the soaking chamber and<br />

the temperature maintained at about 200 o with 25 cms. of vacuum. After an interval<br />

of 10 minutes which period has been found sufficient to remove the moisture from<br />

waste, the requisite quantity of oil (the ratio of oil to waste being 4:1) is discharged<br />

into the soaking chamber through the oil control valves. The oil flowing over the<br />

perforated plate fixed to the inside of the lid, assists proper distribution. The soaking<br />

time should be 40 minutes. No draining is necessary. Thoroughly impregnated<br />

packing is thereafter ready and this should be transferred to a shallow container.<br />

Steam soaking of the reclaimed waste to be carried out by adding 1 Kg. of oil<br />

to 5 Kgs. of old waste. Soaking for a period of 10 minutes would be adequate. In the<br />

case of old waste which may thereafter be transferred to a separate shallow container<br />

for being used along with new steam soaked waste in the proportion already laid<br />

down earlier.<br />

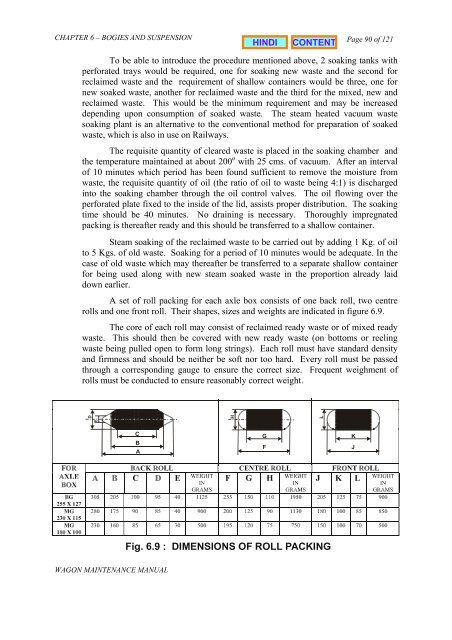

A set of roll packing for each axle box consists of one back roll, two centre<br />

rolls and one front roll. Their shapes, sizes and weights are indicated in figure 6.9.<br />

The core of each roll may consist of reclaimed ready waste or of mixed ready<br />

waste. This should then be covered with new ready waste (on bottoms or reeling<br />

waste being pulled open to form long strings). Each roll must have standard density<br />

and firmness and should be neither be soft nor too hard. Every roll must be passed<br />

through a corresponding gauge to ensure the correct size. Frequent weighment of<br />

rolls must be conducted to ensure reasonably correct weight.<br />

D<br />

C<br />

B<br />

A<br />

Fig. 6.9 : DIMENSIONS OF ROLL PACKING<br />

G<br />

F<br />

K<br />

J