BOGIES AND SUSPENSION - South Central Railway

BOGIES AND SUSPENSION - South Central Railway

BOGIES AND SUSPENSION - South Central Railway

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

CHAPTER 6 – <strong>BOGIES</strong> <strong>AND</strong> <strong>SUSPENSION</strong><br />

WAGON MAINTENANCE MANUAL<br />

Page 63 of 121<br />

There are ten rivet holes on MG & 11 on BG on each axle guard leg. The<br />

bottom hole/holes is/are meant for riveting briddle bar with axle guard leg. Its dia is<br />

17.5 mm (for 16 mm rivet) starting from top two holes in the vertical row and 2/3<br />

holes on the indicated row are meant to rivet the axle guard with the sole bar. The 3rd<br />

rivet hole in case of BG and 3rd & 4th rivet hole in case of MG, from top of the first<br />

row are chamfered on outer face of the axle guard to enable use of countersunk rivets,<br />

thus preventing infringement of bearing spring with axle guard rivets. The horn cheek<br />

is riveted to axle guard with a packing plate in between them through 3rd to 6th rivet<br />

hole in case of BG and 4th to 7th rivet hole in case of MG. In case of MG, the<br />

packing plate is riveted through the third rivet hole in addition.<br />

The bridle bar is riveted to the axle guard through the 8th rivet hole in case of<br />

MG and 7th & 8th rivet hole in case of BG. In addition to the above, BG axle guards<br />

are further secured with the bottom flange of the sole bar channel by an angle cleat.<br />

Angle cleat is riveted to the sole bar and axle guard by three rivets on its each side.<br />

It is very important that the 10/11 th rivet holes are correctly drilled otherwise it<br />

will cause difficulty in securing the axle guard with the sole bar, horn cheek packing<br />

plate and bridle bar with axle guards.<br />

b) AXLE GUARD (LEG TYPE IRCA)<br />

It is made of steel plate Grade ST 42-S ‘A’ to specification No. IS:226. It has<br />

a vertical leg with a sloping arm branching upwards from about 1/3rd distance from<br />

the bottom. The sloping arm after certain distance is again bent to become vertical<br />

and parallel to the main vertical leg. All the three arms are made out of one plate with<br />

vertical arm and sloping arm close to each other. After cutting the sloping arm is hot<br />

bent to required shape. The important sizes of MG axle guard are :-<br />

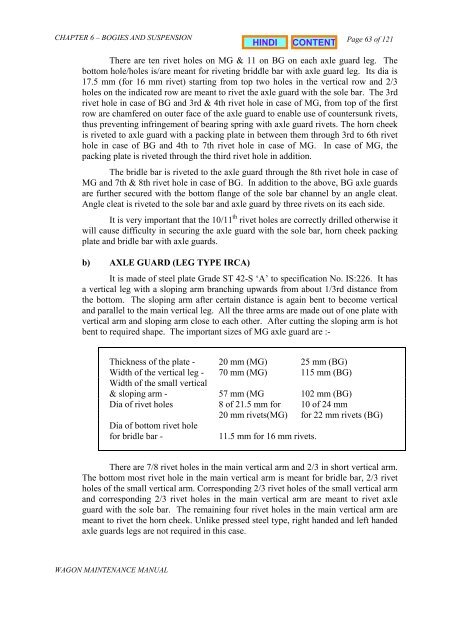

Thickness of the plate - 20 mm (MG) 25 mm (BG)<br />

Width of the vertical leg - 70 mm (MG) 115 mm (BG)<br />

Width of the small vertical<br />

& sloping arm - 57 mm (MG 102 mm (BG)<br />

Dia of rivet holes 8 of 21.5 mm for 10 of 24 mm<br />

20 mm rivets(MG) for 22 mm rivets (BG)<br />

Dia of bottom rivet hole<br />

for bridle bar - 11.5 mm for 16 mm rivets.<br />

There are 7/8 rivet holes in the main vertical arm and 2/3 in short vertical arm.<br />

The bottom most rivet hole in the main vertical arm is meant for bridle bar, 2/3 rivet<br />

holes of the small vertical arm. Corresponding 2/3 rivet holes of the small vertical arm<br />

and corresponding 2/3 rivet holes in the main vertical arm are meant to rivet axle<br />

guard with the sole bar. The remaining four rivet holes in the main vertical arm are<br />

meant to rivet the horn cheek. Unlike pressed steel type, right handed and left handed<br />

axle guards legs are not required in this case.