Perkins L4 Workshop Manual - L-36 Fleet

Perkins L4 Workshop Manual - L-36 Fleet

Perkins L4 Workshop Manual - L-36 Fleet

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

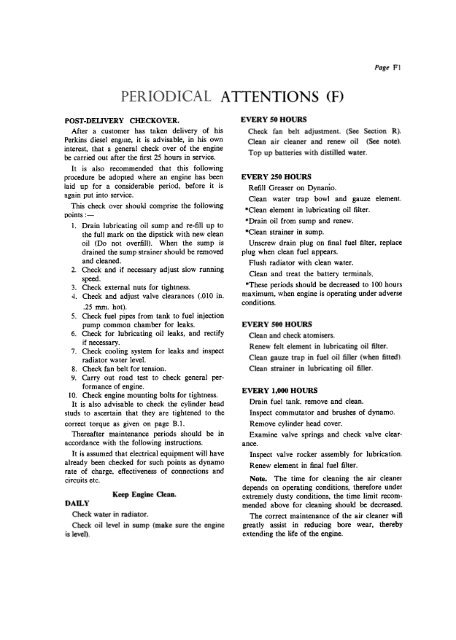

POST-DELIVERY CHECKOVER.<br />

Af ter a customtr bas taken delivery of bis<br />

<strong>Perkins</strong> diesel engille. it is advisable. in bis own<br />

interest. thai a genera I check over of the engine<br />

be carried out af ter the first 25 hours in service.<br />

It is also recommended that this following<br />

procedure he adopted where an engine bas been<br />

laid up tor a considerable period. before it is<br />

again put into service.<br />

This check over should comprise the following<br />

points :-<br />

I. Drain lubricating oil sump and re-fill up to<br />

the ruIl mark on the dipstick with new clean<br />

oil (Do not overfill). When the sump is<br />

drained the sump strainer should he removed<br />

and cleaned.<br />

2. Check and if necessary adjust slow running<br />

speed.<br />

3. Check external nuts tor tightness.<br />

4. Check and adjust valve clearances (.010 in.<br />

.25 mmo hot).<br />

5. Check fuel pipes trom tank to fuel injection<br />

pump common chamher tor leaks.<br />

6. Check tor lubricating oil leaks. and rectify<br />

if necessary.<br />

7. Check cooling system tor leaks and inspect<br />

radiator water level.<br />

8. Check fan belt tor tension.<br />

9. Carry out raad test to check general performance<br />

of engine.<br />

10. Check engine mounting balts tor tightness.<br />

It is also advisable to check the cylinder head<br />

studs to ascertain that they are tightened to the<br />

correct torque as given on page B.l.<br />

Thereafter maintenance periods should he in<br />

accordance with the following instructions.<br />

It is assumed thai electrical equipment will have<br />

already been checked tor such points as dynamo<br />

rate of charge. effectiveness of connections and<br />

circuits etc.<br />

Keep Eogioe Oeso.<br />

DAll..V<br />

Check watc:r in radiator.<br />

Check oil level in sump (make sure the engine<br />

is level),<br />

A TTENTI 0 N S (F)<br />

EVERY SO HOURS<br />

Page FJ<br />

Check fan belt adjustment. (See Section R).<br />

Clean air cleaner and renew Dil (See Date).<br />

Top up batteries with distilled water.<br />

EVERY 250 HOURS<br />

Refill Greaser on Dynamo.<br />

Clean water trap bowl and gauze element.<br />

*Clean element in lubricating oil filter.<br />

*Drain oil trom sump and renew.<br />

*Clean strainer in sump.<br />

Unscrew drain plug on final tuel filter. replace<br />

plug when clean tuel appears.<br />

Flush radiator with clean water.<br />

Clean and treat the battery terminals.<br />

*These periods should be decreased to 100 hours<br />

maximum. when engine is operating under adverse<br />

conditions.<br />

EVERY 500 HOURS<br />

Clean and check atomisers.<br />

Renew feIt element in lubricating oil filter.<br />

Clean gauze trap in fuel oil filler (when fitted)<br />

Clean strainer in lubricating oil filler.<br />

EVERY 1,000 HOURS<br />

Drain fuel tank. remove and clean.<br />

Inspect commutator and brushes of dynamo.<br />

Remove cylinder head cover.<br />

Examine valve springs and check valve clearance.<br />

Inspect valve rocker assembly for lubrication.<br />

Renew element in final fuel filter.<br />

Note. The time for cleaning the air cleaner<br />

depends on operating conditions. therefore under<br />

extremely dusty conditions. the time limit recommended<br />

above for cleaning should he decreased.<br />

The correct maintenance of the air cleaner win<br />

greatly assist in reducing bare wear. thereby<br />

extending the life of the engine.