Perkins L4 Workshop Manual - L-36 Fleet

Perkins L4 Workshop Manual - L-36 Fleet

Perkins L4 Workshop Manual - L-36 Fleet

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

. .<br />

~- Pag~<br />

..,<br />

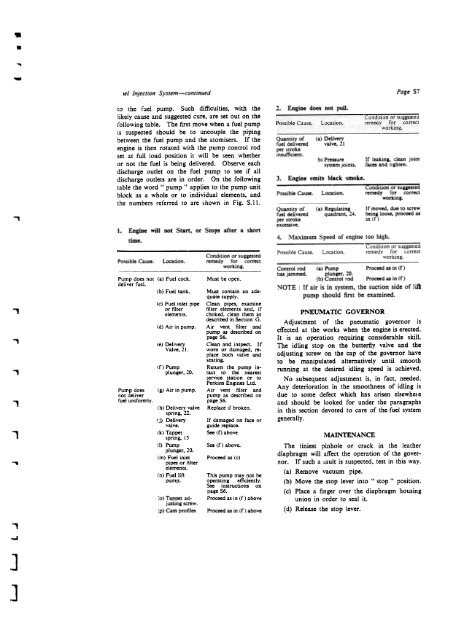

Iel InjectÎon System-continued<br />

to the Cuet pump. Such difficulties, with the<br />

likely cause and suggested cure, are set out on the<br />

following ta bie. The fust move when a Cuel pump<br />

is suspected should be to uncouple the piping<br />

between the fuel pump and the atomisers. If the<br />

engine is then rotated with the pump con trol rod<br />

set at ruil load position it will be seen whether<br />

or not the Cuel is being deliver.ed. Observe each<br />

discharge outlet on the fuel pump to see if all<br />

discharge outlets are in order. On the following<br />

table the word .. pump " applies to the pump unit<br />

block as a whole or to individual elements, and<br />

the numbers reCerred 10 are shown in Fig. S.ll.<br />

1. Engine will not Start, or Stops af ter a short<br />

time.<br />

2. Engine does not pull.<br />

Quantity of (a) Delivery<br />

fuel delivered valve. 21<br />

per stroke<br />

insufficient.<br />

~b) Pressure<br />

system joints.<br />

3. Engine emits black smoke.<br />

57<br />

Ir leaking, clean joint<br />

races and tighten.<br />

Condition or sugaested<br />

Possible Cause. Location. remedy for correct<br />

working.<br />

Quantity of<br />

Cue! delivered<br />

per stroke<br />

excessive.<br />

Ca) Regulating<br />

quadrant, 24.<br />

Ir moved. duo to scrow<br />

being 10050, proceed as<br />

in (r)<br />

Condition or suggcsted<br />

Po~iblc Causc. Location. remedy for correct<br />

,<br />

Pump does not (a) Fuel cock.<br />

deliver fuel.<br />

(b) Fuel tank.<br />

(c) Fuel inlet pipe<br />

or filter<br />

elements.<br />

working.<br />

Must be open.<br />

Must contain an adequate<br />

supply.<br />

Clean pipes. examine<br />

filter elements and. if<br />

choked. clean them as<br />

Control rad (a) Pump Proceed as in (r)<br />

has jammcd. plunger. 20.<br />

(b) Control rod Proceed as in (r)<br />

NOTE : Ir air is in system, the suction side of lift<br />

pump should fust be examined.<br />

PNEUMAnc GOVERNOR<br />

...,<br />

,<br />

,<br />

Pump does<br />

not deliver<br />

fuel uniformly.<br />

(d) Air in pump.<br />

(e) Delivery<br />

Valve.21.<br />

(f) Pump<br />

plunger.20.<br />

(g) Air in pump.<br />

(h) Delivery valve<br />

spring, 22.<br />

(j) Delivery<br />

descnbed in Section G.<br />

Air vent filter and<br />

pump as described on<br />

page 56.<br />

Clean and inspect. Ir<br />

worn or damaged. replace<br />

both valve and<br />

seating.<br />

Return the pump in-<br />

tact to the nearest<br />

service station or to<br />

<strong>Perkins</strong> Engines ltd.<br />

Air vent filter and<br />

pump as described on<br />

page 56.<br />

Replace if broken.<br />

If damaged on face or<br />

Adjustment of tbe pneumatic govemor is<br />

etfected at the works when the engine is erected.<br />

It is an operation requiring considerable skill.<br />

Tbe idling stop on the buttertly valve and tbe<br />

adjusting screw on the cap of the govemor have<br />

to be manipulated altematively until smooth<br />

running at the desired idling speed is achieved.<br />

No subsequent adjustment is, in fact, needed.<br />

Any deterioration in the smoothness of idling is<br />

due to some defect which bas arisen elsewhele<br />

and should he looked for under the paragraphs<br />

in tbis section devoted to care of tbe fuel system<br />

generally.<br />

1<br />

valve.<br />

(k) Tappet<br />

spring, 1 S<br />

guide replace.<br />

See (f) above.<br />

MAINTENANCE<br />

...<br />

(1) Pump<br />

plunger. 20.<br />

(m) Fuel inlet<br />

pipes or filter<br />

elements.<br />

(n) Fuellift<br />

pump.<br />

5ee (f) above.<br />

Proceed as (c)<br />

This pump may not he<br />

operating efficiently.<br />

See instructions on<br />

page 56.<br />

Tbe tmiest pinhole or crack in the leather<br />

diaphragm will affect the operation of the governor.<br />

If such a .ault is suspected. test in this way.<br />

(a) Remove vacuüm pipe.<br />

(b) Move the stop lever into " stop" position.<br />

(c) Place a finger over the diaphragm housing<br />

:0) Tappet adjusting<br />

scrcw.<br />

:p) Cam profiles<br />

Proceed as in (f) above<br />

Proceed as in (f) above<br />

union in order to seal it.<br />

(d) Release the stop lever.<br />

I<br />

,<br />

J<br />

J