Perkins L4 Workshop Manual - L-36 Fleet

Perkins L4 Workshop Manual - L-36 Fleet

Perkins L4 Workshop Manual - L-36 Fleet

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

1<br />

,<br />

Cylinder Head ..\-faintenance-eontinued<br />

Should it be necessary to remove these covers<br />

ncw copper joints should be fitted when they are<br />

replaced.<br />

lf ncw copper joints are not available the old<br />

unes may be used provided they are softened<br />

before being re-fitted.<br />

To soften the joints heat them to a dull red heat<br />

and quench in cold water.<br />

Special care is necessary when refitting these<br />

covers to ensure that there are no leaks at the<br />

joints otherwise there will be a loss of compression<br />

and the efficiency of the engine -:vill be impaired.<br />

Re-assembly Cylinder Head.<br />

Replace valves, valve springs, collars and collet~.<br />

Replace combustion chamber caps and joints.<br />

Fit exhaust manifold gaskets and exhaust<br />

manifold.<br />

Replacing Cylinder Head.<br />

Before replacing cylinder head it is extremely<br />

important to ensure that the cylinder block and<br />

cylinder head races are perfectly clean.<br />

When replacing the cylinder head a new gasket<br />

should be used. Cover both sides with a thin<br />

coating of good jointing compound and before<br />

placing over the cylinder head studs ensure that<br />

the gasket is correctly positioned. The gasket is<br />

marked to indicate hcw it should be replaced.<br />

Having placed the gas ket in position ensure that<br />

the cylinder bead face is perfectly clean and place<br />

in position over the cylinder head studs.<br />

[J.- @~6 2~ ."<br />

Page H3<br />

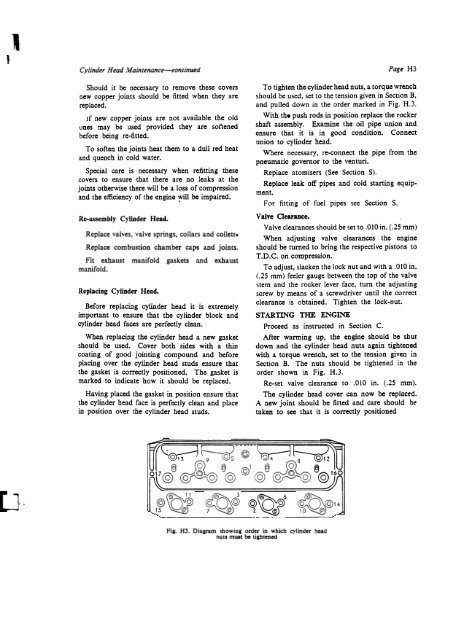

To tighten the cylinder head Duts, a torque wrench<br />

should be used, set to the tension given in Section B,<br />

and pulled down in the order marked in Fig. H.3.<br />

With tb. push rods in position replace tbe rocker<br />

shaft assembly. Examine the oil pipe union and<br />

ensure that it is in good condition. Connect<br />

union to cylinder head.<br />

Where necessary, re-connect the pipe from the<br />

pneumatic governor to the venturi.<br />

Replace atomisers (See Section S).<br />

Replace leak off pipes and cold starting equipment.<br />

For fitting of fuel pipes see Section S.<br />

Valve Clearance.<br />

Valve clearances should be set to .010 in. (.25 mIn)<br />

When adjusting valve clearances the engine<br />

should he turned to bring the respective pistons to<br />

T .D.C. on compression.<br />

To adjust, slacken the lock nut and with a .010 in.<br />

(.25 mm) feeIer gauge between the top of the valve<br />

stem and the rocker lever face, turn the adjusting<br />

screw by means of a screwdriver until the correct<br />

clearance is obtained. Tighten the lock-nut.<br />

STARTING THE ENGINE<br />

Proceed as instructed in Section C.<br />

Af ter warming up, tbe engine should be sbut<br />

down and the cylinder head Duts again tightened<br />

witb a torque wrench, set to the tension given in<br />

Section B. The nuts should be tightened in the<br />

order shown in Fig. H.3.<br />

Re-set valve clearance to .010 in. (.25 mm).<br />

Tbe cylinder head cover cao aow be replac~d.<br />

A ncw joint should be fitted and care should b~<br />

taken to sec that it is correctly positioned<br />

§<br />

'-;;;;'<br />

Fig. H3. Diagram showing order in which cylinder head<br />

nut.! must bc tightened