Perkins L4 Workshop Manual - L-36 Fleet

Perkins L4 Workshop Manual - L-36 Fleet

Perkins L4 Workshop Manual - L-36 Fleet

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

~<br />

Page Q2<br />

di stance piece and then press on front bearing.<br />

Ensure that each hearing end cover faces<br />

outwards towards the ends of the shaft.<br />

2. The front seal retaining plate should then he<br />

placed in position against the back face of<br />

the rear hearing. This retaining plate is<br />

. dished' and when positioned, the centre<br />

of the plate must not be in contact with the<br />

rear bearing.<br />

3. Fit the feit seal and seal housing, so that these<br />

bear on the retaining plate.<br />

4. Prcss the water pump thrower on to the shaft<br />

so that the thrower Range faces towards the<br />

rear bearing.<br />

S. The whole of the foregoing assembly should<br />

then be pressed into the water pump body<br />

from the front end, and the circlip securely<br />

positioned in the recess forward of the front<br />

bearing. Before pressing the assembly into<br />

the pump body, however, the bearings and<br />

the space between the two bearings should be<br />

half filled with a high melting point grease.<br />

6. Fit the rear seal into the pump body ensuring<br />

that the carbon face is positioned towards the<br />

rear ofthe pump body. When fitted, the seal<br />

must rest squarelyon its scat and not be<br />

canted in any way.<br />

7. At this stage the shaft should be turned by<br />

0<br />

~<br />

hand to ensure that ther\: is no undue re.<br />

.istance to rotation.<br />

8. Press on the pulley making certain that no<br />

rearward axial movemem of the shaft is<br />

incurred.<br />

9. The impelle( should now be pressed on to the<br />

shaft. With the impeller fitted. care should<br />

be taken to ensure that a clearance of .015-<br />

.025 in. (.38 to .64 mm) is maimained between<br />

the inner edge of the impeller vanes and the<br />

water pump body. As a guide to obtaining a<br />

correct clearance in this respect, the impeller<br />

should be so positioned as to allow a straight<br />

edge to simultaneously touch the back face of<br />

the pump body and the two raised extractor<br />

hole races in the teat of the impeller.<br />

10. Refit plain washer and slotted nut and secure<br />

with a new split pin.<br />

Modified Water Pump<br />

0 Cl)<br />

---<br />

@<br />

.015<br />

I<br />

~<br />

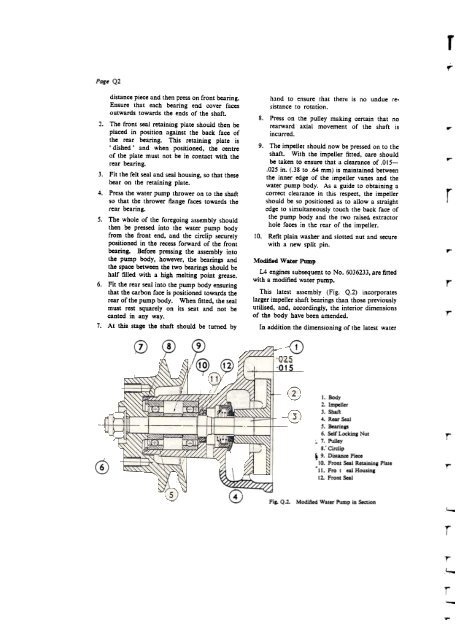

<strong>L4</strong> engines subsequent to No. 60<strong>36</strong>233, arc fittcd<br />

with a modificd water pump.<br />

This latcst assembly (Fig. Q.2) incorporates<br />

largcr impcller shaft bcarings than those prcviously<br />

utiliscd, and, accordingJy, thc interior dimensions<br />

of tbc body have been amcnded.<br />

-'<br />

~~~~~.7?"j<br />

In addition the dimensioning of the latcst water<br />

1. Body<br />

2. Impe11cr<br />

3. Shaft<br />

4. Rcar Scal<br />

5. Bcarings<br />

6. Sclf Locking Nut<br />

;. 7. Pulley<br />

8: Circlip<br />

k 9. Distancc Piccc<br />

'10. Front ScaI Rctaining Platc<br />

-11. Fro t cal Housing<br />

12. Front Scal<br />

0~. Q.l. Modified Water Pump in Section<br />

r<br />

f'"<br />

r<br />

,...<br />

r<br />

r<br />

r<br />

r<br />

r<br />

r<br />

-