Perkins L4 Workshop Manual - L-36 Fleet

Perkins L4 Workshop Manual - L-36 Fleet

Perkins L4 Workshop Manual - L-36 Fleet

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

1<br />

(J'<br />

J.<br />

CYLINDER HEAO<br />

The Diesel engine rarely, if ever, needs the<br />

periodical decarbonising that is accepted as a<br />

matter of course with the petrol engine, insofar<br />

that in an engine operating on the diesel cycle,<br />

carbon, beyond a superficial coating, does not<br />

fonn and accumulate in the combustion chamber<br />

and on the pistons as in the case of the petrol<br />

engine.<br />

O~ing to its higher therm al efficiency, the valves<br />

of the Diesel engine are also much more free from<br />

trouble due to overheating; that is, of course,<br />

providing the engine is reasonably maintained.<br />

Af ter aperiod, depending upon the condition~<br />

under which the engine is operated, the valves<br />

may need attention. This will become apparent<br />

by loss of compression, in which case a top overhaul<br />

may be necessary.<br />

Preparation.<br />

Begin by assembling all the joints and other<br />

parts required, as called for in the <strong>Perkins</strong> parts<br />

List.<br />

Drain all water from the radiator and cylinder<br />

block. The drain cock for the cylinder block is<br />

on the fuel pump side of the engine. Disconnec<br />

the exhaust pipe from the engine exhaust manifold t<br />

Uncouple extemal connections to the cylinder head.<br />

Cylinder Head. To Remove.<br />

Remove the air cleaner.<br />

Take oir cylinder head cover.<br />

Uncouple union on oil pipe to rocker assembly.<br />

Remove Duts holding rocker shaft assembly.<br />

Remove retaining plates and lift oir rocker<br />

assembly, bringing above named oil pipe with it.<br />

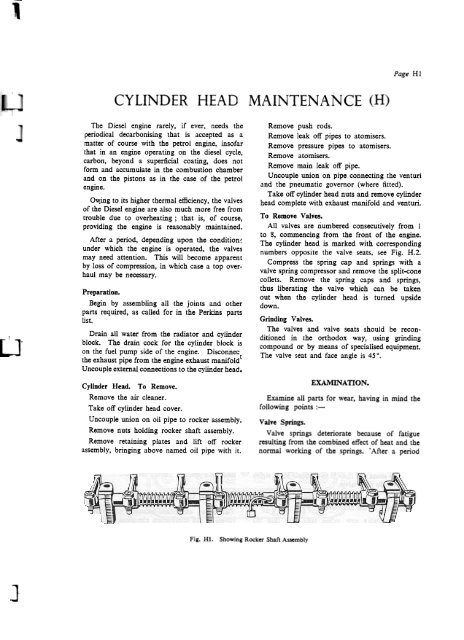

Fig. Hl Showing Rocker Shaft Assembly<br />

Page Hl<br />

Remove push rods.<br />

Remove leak off pipes to atomisers.<br />

Remove pressure pipes to atomisers.<br />

Remove atomisers.<br />

Remove main leak off pipe.<br />

Uncouple union on pipe connecting the venturi<br />

and the pneuma tic governor (where fitted).<br />

Take off cylinder head Duts and remove cylinder<br />

head complete with exhaust manifold and venturi.<br />

To Remove Valves.<br />

All valves are numbered consecutively from I<br />

to 8, commencing from the front of the engine.<br />

The cylinder head is marked with corresponding<br />

numbers opposite the valve seats, see Fig. H.2.<br />

Compress the spring cap and springs with a<br />

valve spring compressor and remove the split-cone<br />

collets. Remove the spring caps and springs,<br />

thus liberating the valve which can be taken<br />

out when the cylinder head is turned upside<br />

down.<br />

Grinding Valves.<br />

The valves and valve seats should be reconditioned<br />

in the orthodox way, using grinding<br />

compound or by means of specialised equipment.<br />

The valve seat and face angle is 45°,<br />

EXA1\IUN A nON.<br />

Examine all parts for wear, having in mind tbe<br />

following points:-<br />

Valve Springs.<br />

Valve springs deteriorate because of fatigue<br />

resulting from the combined effect of heat and the<br />

normal working of the springs. . Af ter aperiod