pdf, 12 MiB - Infoscience - EPFL

pdf, 12 MiB - Infoscience - EPFL

pdf, 12 MiB - Infoscience - EPFL

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

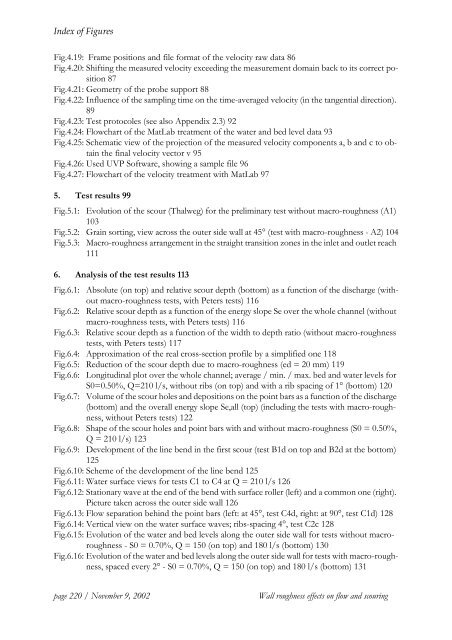

Index of Figures<br />

Fig.4.19: Frame positions and file format of the velocity raw data 86<br />

Fig.4.20: Shifting the measured velocity exceeding the measurement domain back to its correct position<br />

87<br />

Fig.4.21: Geometry of the probe support 88<br />

Fig.4.22: Influence of the sampling time on the time-averaged velocity (in the tangential direction).<br />

89<br />

Fig.4.23: Test protocoles (see also Appendix 2.3) 92<br />

Fig.4.24: Flowchart of the MatLab treatment of the water and bed level data 93<br />

Fig.4.25: Schematic view of the projection of the measured velocity components a, b and c to obtain<br />

the final velocity vector v 95<br />

Fig.4.26: Used UVP Software, showing a sample file 96<br />

Fig.4.27: Flowchart of the velocity treatment with MatLab 97<br />

5. Test results 99<br />

Fig.5.1: Evolution of the scour (Thalweg) for the preliminary test without macro-roughness (A1)<br />

103<br />

Fig.5.2: Grain sorting, view across the outer side wall at 45° (test with macro-roughness - A2) 104<br />

Fig.5.3: Macro-roughness arrangement in the straight transition zones in the inlet and outlet reach<br />

111<br />

6. Analysis of the test results 113<br />

Fig.6.1: Absolute (on top) and relative scour depth (bottom) as a function of the discharge (without<br />

macro-roughness tests, with Peters tests) 116<br />

Fig.6.2: Relative scour depth as a function of the energy slope Se over the whole channel (without<br />

macro-roughness tests, with Peters tests) 116<br />

Fig.6.3: Relative scour depth as a function of the width to depth ratio (without macro-roughness<br />

tests, with Peters tests) 117<br />

Fig.6.4: Approximation of the real cross-section profile by a simplified one 118<br />

Fig.6.5: Reduction of the scour depth due to macro-roughness (ed = 20 mm) 119<br />

Fig.6.6: Longitudinal plot over the whole channel; average / min. / max. bed and water levels for<br />

S0=0.50%, Q=210 l/s, without ribs (on top) and with a rib spacing of 1° (bottom) <strong>12</strong>0<br />

Fig.6.7: Volume of the scour holes and depositions on the point bars as a function of the discharge<br />

(bottom) and the overall energy slope Se,all (top) (including the tests with macro-roughness,<br />

without Peters tests) <strong>12</strong>2<br />

Fig.6.8: Shape of the scour holes and point bars with and without macro-roughness (S0 = 0.50%,<br />

Q = 210 l/s) <strong>12</strong>3<br />

Fig.6.9: Development of the line bend in the first scour (test B1d on top and B2d at the bottom)<br />

<strong>12</strong>5<br />

Fig.6.10: Scheme of the development of the line bend <strong>12</strong>5<br />

Fig.6.11: Water surface views for tests C1 to C4 at Q = 210 l/s <strong>12</strong>6<br />

Fig.6.<strong>12</strong>: Stationary wave at the end of the bend with surface roller (left) and a common one (right).<br />

Picture taken across the outer side wall <strong>12</strong>6<br />

Fig.6.13: Flow separation behind the point bars (left: at 45°, test C4d, right: at 90°, test C1d) <strong>12</strong>8<br />

Fig.6.14: Vertical view on the water surface waves; ribs-spacing 4°, test C2c <strong>12</strong>8<br />

Fig.6.15: Evolution of the water and bed levels along the outer side wall for tests without macroroughness<br />

- S0 = 0.70%, Q = 150 (on top) and 180 l/s (bottom) 130<br />

Fig.6.16: Evolution of the water and bed levels along the outer side wall for tests with macro-roughness,<br />

spaced every 2° - S0 = 0.70%, Q = 150 (on top) and 180 l/s (bottom) 131<br />

page 220 / November 9, 2002<br />

Wall roughness effects on flow and scouring