You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Grundfos</strong> E-<strong>pumps</strong><br />

2<br />

Application examples<br />

As discussed earlier, speed control of <strong>pumps</strong> is an<br />

efficient way of adjusting pump performance to the<br />

system.<br />

In this section, we will discuss the possibilities of<br />

combining speed-controlled <strong>pumps</strong> with PI controllers<br />

and sensors measuring system parameters, such as<br />

pressure, differential pressure and temperature.<br />

On the following pages, the different options will be<br />

presented through examples.<br />

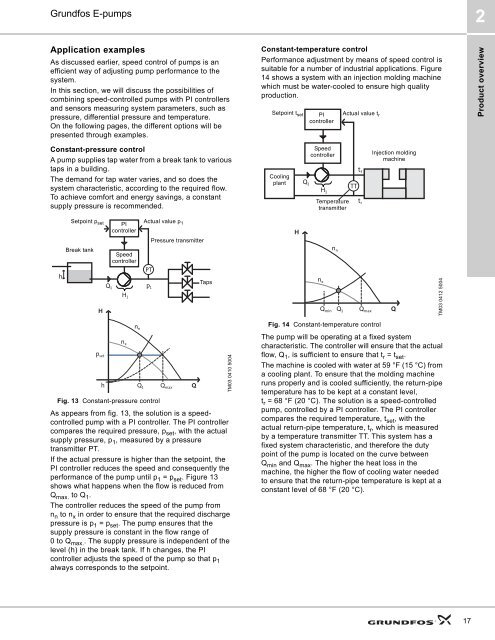

Constant-temperature control<br />

Performance adjustment by means of speed control is<br />

suitable for a number of industrial applications. Figure<br />

14 shows a system with an injection molding machine<br />

which must be water-cooled to ensure high quality<br />

production.<br />

Setpoint t set t set<br />

PI<br />

controller<br />

Actual value t r<br />

Product overview<br />

Constant-pressure control<br />

A pump supplies tap water from a break tank to various<br />

taps in a building.<br />

The demand for tap water varies, and so does the<br />

system characteristic, according to the required flow.<br />

To achieve comfort and energy savings, a constant<br />

supply pressure is recommended.<br />

Cooling<br />

plant<br />

Speed<br />

controller<br />

Temperature<br />

transmitter<br />

Injection molding<br />

machine<br />

h<br />

Setpoint p set set<br />

Break Break tank<br />

tank<br />

PT<br />

Q 1<br />

p 1<br />

H 1<br />

H<br />

n n<br />

n x<br />

p set<br />

h<br />

PI-<br />

controller<br />

Speed<br />

controller<br />

Q 1<br />

Fig. 13 Constant-pressure control<br />

Actual value p 1<br />

Pressure transmitter<br />

transmitter<br />

Q max<br />

As appears from fig. 13, the solution is a speedcontrolled<br />

pump with a PI controller. The PI controller<br />

compares the required pressure, p set , with the actual<br />

supply pressure, p 1 , measured by a pressure<br />

transmitter PT.<br />

If the actual pressure is higher than the setpoint, the<br />

PI controller reduces the speed and consequently the<br />

performance of the pump until p 1 = p set . Figure 13<br />

shows what happens when the flow is reduced from<br />

Q max. to Q 1 .<br />

The controller reduces the speed of the pump from<br />

n n to n x in order to ensure that the required discharge<br />

pressure is p 1 = p set . The pump ensures that the<br />

supply pressure is constant in the flow range of<br />

0 to Q max. . The supply pressure is independent of the<br />

level (h) in the break tank. If h changes, the PI<br />

controller adjusts the speed of the pump so that p 1<br />

always corresponds to the setpoint.<br />

Q<br />

Taps<br />

TM03 0410 5004<br />

Fig. 14 Constant-temperature control<br />

The pump will be operating at a fixed system<br />

characteristic. The controller will ensure that the actual<br />

flow, Q 1 , is sufficient to ensure that t r = t set .<br />

The machine is cooled with water at 59 °F (15 °C) from<br />

a cooling plant. To ensure that the molding machine<br />

runs properly and is cooled sufficiently, the return-pipe<br />

temperature has to be kept at a constant level,<br />

t r = 68 °F (20 °C). The solution is a speed-controlled<br />

pump, controlled by a PI controller. The PI controller<br />

compares the required temperature, t set , with the<br />

actual return-pipe temperature, t r , which is measured<br />

by a temperature transmitter TT. This system has a<br />

fixed system characteristic, and therefore the duty<br />

point of the pump is located on the curve between<br />

Q min and Q max . The higher the heat loss in the<br />

machine, the higher the flow of cooling water needed<br />

to ensure that the return-pipe temperature is kept at a<br />

constant level of 68 °F (20 °C).<br />

TM03 0412 5004<br />

17